U.S. Army Cpl. Kevin Dehaven uses his .300 Win. Mag. U.S. M2010 rifle’s scope to scan the valley while providing security on Observation Post Mangol in the Nari district of Afghanistan’s Kunar province, Feb. 8, 2012. The Mk 248 MOD 1 cartridge is changing the nature of sniping.

"One day, a group of three insurgents appeared on the shore upriver, out of range at around 1,600 yards. Apparently realizing that they were safe, they began mocking us like a bunch of juvenile delinquents. But 1,600 yards was so far that my scope wouldn’t even dial up the shooting solution. So I did a little mental calculation and adjusted my aim with the help of a tree behind one of the grinning insurgent idiots making fun of us. I the shot. The moon, Earth, and stars aligned. God blew on the bullet, and I gut-shot the jackass.”

The above excerpt, taken from Navy SEAL Chris Kyle’s book, American Sniper, illustrates why the .300 Win. Mag.—in this case, the older Mk 248 MOD 0 load—is the “reach-out-and-touch-someone” round of what I call the Special Forces’ “fearsome triad” of precision ammunition: the two other offerings being the Mk 316 MOD 0 (7.62x51 mm NATO) and the Mk 262 MOD 1 (5.56x45 mm NATO). Missing from this assemblage is the newer .338 Lapua Mag., which, although seeing service with U.S. Special Forces since the early 1990s, isn’t nearly as common as the others. Moreover, because the Mk 248 MOD 1 load has external ballistics comparable to the .338 Lapua Mag.—and at a significant cost savings—it’s probable that the popularity of the .300 Win. Mag. will continue to grow disproportionately to that of the .338 Lapua Mag. Indeed, the .300 Win. Mag. is changing the nature of sniping.

An Unusual Journey

Introduced in the Model 70 in 1963, the .300 Win. Mag. was one of Winchester’s four mid-20th-century “short”-magnum cartridges that could be utilized in a hunting rifle with a standard-length action; the three others are the .264 Win. Mag., .338 Win. Mag. and .458 Win. Mag. As a shortened, blown-out .375 H&H Mag. case served as the parent for the .300 Win. Mag., its bottlenecked brass has the same case head diameter and belt of its elder. By reducing the body taper and moving the shoulder forward—to increase propellant capacity—the .300 Win. Mag. case’s short neck length challenged conventional wisdom at the time. Short necks, it was thought, were a detriment to accuracy. It was believed that, at a minimum, the neck length had to match the width of the bullet, and even longer was better. Obviously, this belief has since been disproved time and again.

Since its inception, the .300 Win. Mag. has proven to be an extremely popular cartridge for hunting big-game animals; in fact, it’s likely the most-used .30-cal. magnum in North America—if not worldwide—for such purposes. The attributes that endear the cartridge to ardent hunters—especially those who pursue larger species and lengthier shot distances—and long-range match shooters caught the attention of the U.S. Navy.

According to “The Development of the Navy .300 Winchester Magnum Cartridge Configuration Naval Surface Warfare Center-Crane (NWSC)” document, “Throughout the 1980s the Navy focused on improving weapons and ammunition for match competition and sniper use. In the late 1980s the focus was turned to the .300 Winchester Magnum (.300 Win Mag) cartridge. This was because the .300 Win Mag was (1) commercially produced in economic quantities; (2) commercial weapons could be easily modified for use in a military environment; and (3) the cartridge was proven in long-range match competition. The two users of this cartridge in the Navy were to be the Match Competition Team and Naval Special Warfare Forces.”

As for build specifications, the aforementioned document revealed, “The general requirements for the cartridge were (1) the projectile had to be consistent with the Law of War obligations of the United States; (2) the chamber pressure had to be within SAAMI limits at 70° F, 125° F and -40° F; (3) velocity was to be maximized while staying within the SAAMI pressure limits; and (4) a 10-inch extreme spread at 1,000 yards was desired, a 15-inch extreme spread was required.” Straying from Sporting Arms and Ammunition Manufacturers’ Institute, Inc. (SAAMI) standards, which lists a maximum cartridge overall length (C.O.L.) of 3.340", this round’s maximum C.O.L. was lengthened to 3.50". This was done to increase propellant space and reduce the bullet-jump distance.

Originally, the average extreme spread of the .300 Win. Mag. loads was not to exceed 8.0" at 600 yds., or 3.5" at 300 yds.; however, the prerequisite had to be re-written to a 2.3" maximum average spread at 200 yds. due to range constraints. Moreover, the muzzle velocity mandate was 2950 f.p.s. (+/- 30 f.p.s.) with a top standard deviation of 25 f.p.s. Finally, the bullet had to weigh between 180 and 190 grs. and have a full-metal-jacket design.

Although Federal Cartridge Co. won the contract in 1987, its celebration was short-lived; the company’s bullet of choice, the 180-gr. Sierra MatchKing, would lead to the load’s condemnation. In 1988, the Navy Match Rifle Team found that the projectile was becoming unstable at 800 yds. “and passing through the target sideways at 1000 yards.” This was confirmed by NSWC-Crane. That mattered little though, as “the projectile was ruled by the Navy Judge Advocate General (JAG) to be unacceptable for use in combat based upon the appearance of an open-tip despite being burnished.” Burnishing the tip was performed to close the open tip, but due to the projectile’s now-shorter length, it also negatively affected the bullet’s center of gravity and possibly impacted its symmetry in the process.

As an aside, thanks to the knowledge and dedication of W. Hays Parks, Chief, International Law Branch, Int’l Affairs Division, U.S. Army, in time open-tip match (OTM) bullets, such as the Sierra MatchKing, would be permitted for use in combat. Keep in mind that the OTM vs. hollow point argument isn’t irrelevant history; in fact, in a recent article written by W. Park Hays himself entitled, “Open Tip Match: When A ‘Hollow Point’ is Not a Hollow Point,” he mentioned that, in 2006, a U.S. Army sniper had difficulty obtaining a resupply of M118LR in Iraq stemming from outdated wording on ammunition packaging. It has since been remedied.

As an interim solution to the aforementioned fiasco, the 180-gr. MatchKing projectiles from a specific lot of ammunition were pulled and replaced with Lapua 185-gr. full-metal-jacket bullets. Unlike the MatchKing loads, which had an average extreme spread of 12.3" at 800 yds., the Lapua-tipped loads averaged 9.1" at that same distance. Yielding 15.4" at 1,000 yds., the modified loads were far better performers.

A contracting action to procure .300 Win. Mag. ammunition loaded with the Lapua bullet atop of IMR-4350 propellant was put into place in 1990. Hunter Shack Mfg. (HSM) of Missoula, Mont., produced the ammunition. The “Development of the Navy .300 Winchester Magnum Cartridge Configuration” NSWC-Crane document indicates that, whereas all lots of HSM ammunition had the chamber pressure exceed SAAMI spec at 125° F. (while the Federal loads didn’t), in all but one acceptance test the HSM loads proved to be more accurate than those from Federal. For example, when the Federal loads averaged 2.3" and 1.615" at 200 yds., the HSM’s average extreme spreads were 1.66", 1.47" and 1.37". Despite these showings, the Navy decided to fund development of a load that remediated the accuracy and pressure issues; it didn’t want a Band-Aid fix.

The M852 (7.62x51 mm NATO) cartridge, which featured a Sierra 168-gr. MatchKing bullet, “was authorized [in 1990] for use in combat by snipers by the Army and Navy JAG offices.” But, as the NSWC-Crane documents mention, “Due to the JAG decision [about Open Tip Match bullets] and accuracy concerns, it was decided that a 190 grain MatchKing-type HPBT projectile would be pursued instead of the 185 grain FMJ projectile [from Lapua].” Parks’ actions “paved the way” for adoption of the Sierra 190-gr. MatchKing.

With the bullet selected, the following propellants were evaluated for use in the new load: Accurate 3100, IMR-4350 and IMR-7828, and Reloder 19 and 22. The latter two were found to be least affected by temperature, maintain safe chamber pressures and provide “statistically better” accuracy.

As cited in the NSWC-Crane documents, performance specifications for the load called for: “(1) the use of a 190 grain HPBT match projectile; (2) the use of Reloder 19 or 22 propellant; (3) commercial 70-30 alloy brass case; (4) a commercial match quality primer; (4) a nominal velocity of 3,000 f.p.s; (5) pressure limits within SAAMI at -40° F., 70° F., and 125° F.; and (6) an average extreme spread of no greater than 2.25" at 200 yards., the maximum allowable individual extreme spread is 3.5".” After testing of Crane Division, NSWC-constructed ammunition was completed, a procurement action was initiated. Federal Cartridge Co. was awarded the contract in 1992.

Federal-manufactured loads averaged between 2975 and 3001 f.p.s., producing acceptable chamber pressure, and maximum average extreme spreads of 1.30" (first article lot), 1.47", 1.97" and 1.72". After these evaluations, the loads were subjected to a host of torturous, but realistic, tests, including: toxic fumes, sound pressure levels and rough handling, among many others. Only then were they given to the Navy Match Rifle Team and select Special Warfare Units—it was authorized for use in combat by snipers on Nov. 23, 1993—for evaluation. In response to the new loads, the former reported, “the competitive level of the shooters has increased because of these cartridges,” and the latter described “highly favorable” results. The load, now known as A191 (i.e. Mk 248 MOD 0), was what Chris Kyle used to eliminate the taunting terrorist at 1,600 yds.

The Pinnacle: Mk 248 MOD 1

As successful as the Mk 248 MOD 0 was, its “published” effective range is 1,200 yds. Obviously, Kyle surpassed that distance considerably with his remarkable shooting. Still, due to the terrain and circumstances in Afghanistan and Iraq, NSWC-Crane desired a load that could increase the sniper’s effective range to 1,500 yds., as well as decrease wind deflection (for less dope adjustments) and use a propellant with minimal muzzle flash and that was temperature-stable (rated from -25° F. to 165° F.). Concerning the latter, one must not only take into account the air temperature, which approaches 120° F., but also the rifle’s heat before (i.e. baking in the sun) and after an engagement. Accuracy also had to be comparable to the A191 load.

According to a public domain Naval Sea Systems Command (NAVSEA) Warfare Centers-Crane PowerPoint presentation, the initial idea was to develop a 250-gr. load for the .338 Lapua Mag. It was discovered, however, that the .300 Win. Mag. was capable of delivering external ballistics that were virtually identical to that of the .338. Jeff Hoffman, owner of Black Hills Ammunition, contributed greatly to this newfound perspective of the .300 Win. Mag.

Hearing about NSWC-Crane’s call for improved long-distance targeting, Hoffman contacted its personnel via email in March 2005 with suggestions about how to extend the effective range of the .300 Win. Mag. Due to his experience with manufacturing Mk 248 Mod 0 ammunition—not to mention Mk 316 MOD 0-like and Mk 262 MOD 1 contract loads—he clearly understood what steps needed to be taken. In the email, Hoffman wrote, “The current ammunition utilizes a 190-gr. Sierra MatchKing at 2950 f.p.s. At 59° F. at sea level it can be expected to remain supersonic to about 1,350 yds. If we were to load with a Sierra 220-gr. projectile at 2800 f.p.s., the supersonic range would be increased to about 1,500 yds. This is a gain of over 10 percent.” Moreover, he added that, in a 10-m.p.h. full-value wind, at 1,350 yds. the 220-gr. MatchKing drifts 23.6" less than the 190-gr. version—a 17 percent difference. As Hoffman pointed out, considering that a human is approximately 20" wide, that’s a marked change. And, the 220-gr. MatchKing has 35 percent more energy at that same distance than does the 190-gr. version. Lastly, he explained that components were readily available over the counter and, when assembled, required minimal changes to “dope.”

The NAVSEA Warfare Centers-Crane Power Point presentation provided a synopsis of what happened during testing. In addition to Lapua 250-gr. Scenar and Sierra 250- and 300-gr. MatchKings in the .338 Lapua Mag., 210- and 220-gr. MatchKings were tested in the .300 Win. Mag. Velocity and accuracy were examined at 1,000 yds., and chamber pressure was monitored, too.

With the exception of the 300-gr. MatchKing, the loads met the accuracy requirements. Interestingly, due to their high ballistic coefficients (BC), the 210- (.670 BC) and 220-gr. (.629 BC) .30-cal. MatchKings from the .300 Win. Mag. retained 1557 f.p.s. and 1550 f.p.s. at 1,000 yds., while the 250-gr., .33-cal. MatchKing (.587 BC) and Scenar (.675 BC) were traveling at 1594 and 1544 f.p.s., respectively. Of course, the energy levels of the .33-cal. bullets would be greater than their thinner counterparts. For example, the 210-gr. MatchKing would have 1,130 ft.-lbs. of energy remaining at 1,000 yds. and the 220-gr. MatchKing 1,174 ft.-lbs. On the other hand, the 250-gr. Scenar would have 1,323 ft.-lbs. of energy remaining, while the 250-gr. MatchKing would have 1,410 ft.-lbs. But the Navy didn’t even list energy as a factor; remember, these are non-expanding bullets and you must consider the target.

In the end, though, the 220-gr. Sierra MatchKing .300 Win. Mag. load won the day. First, there was considerable cost savings. Why? Not only could it be fired in existing guns (not to mention they were much lighter and more maneuverable), but .338 Lapua Mag. ammunition costs more in general. Accuracy and velocity retention of the .30-cal. bullets was comparable to the .33-cal. projectiles. Whereas the 210-gr. bullet was relatively new at the time, the 220-gr. variant was well-established and, thus, got the nod. Talking recently with Hoffman, he stated that, in hindsight, he wished that the 210-gr. MatchKing had been selected. New at the time of testing, he now prefers it over the 220-gr. version.

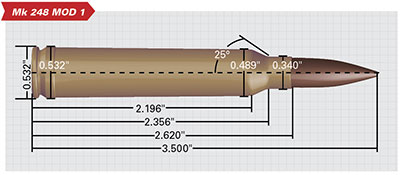

According to “Detail Specification Cartridge, .300 Winchester Magnum Match, MK 248 Mod 1, DODIC AB43, NSN 1305-01-568-7504, Revision A, 17, March 2009,” outside of the requirements to use the Sierra 220-gr. MatchKing, a specific case composition and markings, a large match rifle primer (and seating depth), and Hodgdon H1000 propellant, the loaded cartridge had to be 3.450" (minimum) to 3.50" (maximum) in length, which, again, is longer than SAAMI spec. Using the aforementioned propellant, staying within the SAAMI maximum average pressure (MAP) and still achieving the specified 2850-f.p.s. (+/- 50 f.p.s.) isn’t possible; in fact, the allowable chamber pressure for the load is significantly higher than is permitted by SAAMI. That is interesting because in the “Notes” section, under “Intended Use” it states, “The MK 248 MOD 1 cartridge covered by this specification is for use in the Remington 700 family of weapons (bolt-action only) chambered for .300 Winchester Magnum cartridges.” Additionally, it stated, “Test barrel has to be 24.000 +/- 0.010 inches long. Test weapons shall be two each sniper rifles and suppressors as specified in the solicitation. No alteration allowed.”

As for accuracy, “The extreme spread of any individual 10-shot group shall not exceed 4.5 inches at 300 yards. The average extreme spread of ten, 10-shot groups shall not exceed 3.5 inches at 300 yards. The extreme spread of any individual 10-shot group shall not exceed 9.0 inches at 600 yards. The average extreme spread of ten, 10-shot groups shall not exceed 7.0 inches at 600 yards.” Function and casualty requirements were mandated, too.

In the end, the design goals were met. First, the effective range was increased to 1,500 yds. with reduced wind deflection, and propellant stability across the -25° F to 165° F temperature range, with accuracy comparable to the existing A191 load. Production of the new Mk 248 MOD 1 (DODIC AB43) by Federal Cartridge Co. began on Sept. 26, 2010, and the first shipments arrived in Afghanistan in January 2011. It has become the new standard.

Handloading

Military MK 248 MOD 1 ammunition produced by Federal Cartridge Co. and Black Hills Ammunition is unavailable to consumers—and for good reason. Due to the well-above-average pressures and longer-than-normal C.O.L., deciding to sell such a load to consumers would have been unwise. But, you can safely handload to approach (not achieve or exceed) the 2850-f.p.s. velocity of the military round.

There is a wide selection of propellants suitable for use in the .300 Win. Mag.; however, for this project I selected two of the options that were listed within this article—IMR-7828 and Hodgdon H1000. Even though it was eliminated from contention when the A191/Mk 248 MOD 0 round was being developed, I’ve experienced good performance with IMR-7828 in a host of .30-cal. magnums. It was worth a try. As for H1000, not only have I encountered much success with it through the years, but it’s also the propellant that’s used in the Mk 248 MOD 1 loads. Unlike IMR-7828, H1000 benefits from temperature insensitivity and reduced muzzle flash—two of the reasons that NWSC-Crane mandated its use. In addition to the above-mentioned propellants, I used Winchester brass and Federal GM215M primers. The Sierra 220-gr. MatchKings were loaded to give a C.O.L. of 3.340".

To achieve an apples-to-apples comparison with regard to velocities, 10 consecutive shots with each load were fired from a 24"-barreled Thompson/Center Dimension—topped with a Leupold VX-3 8.5-25X 50 mm LR Target scope—through a ProChrono Digital chronograph at 10 ft. Accuracy testing followed American Rifleman protocol—five consecutive, five-shot groups were fired at 100 yds. from the combination of a bipod and a sandbag rest.

Settling on 71.2 grs. of IMR-7828, the 220-gr. MatchKing attained 2736-f.p.s. muzzle velocity—only 114 f.p.s. slower than the military round. The standard deviation was 16. With that velocity, the projectile has 3,657 ft.-lbs. of energy at the muzzle and, when zeroed at 300 yds., the bullet drops 30.3" at 500 yds. and 270.6" at 1,000 yds. At the latter, it still has 1,110 ft.-lbs. of energy remaining. As for accuracy, it averaged 1.20".

With H1000, I found 74.0 grs. provided the perfect combination of speed and accuracy. For 10 shots the load averaged 2686 f.p.s.—164 f.p.s. slower than the Mk 248 MOD 1—and had a standard deviation of 11. Energy at the muzzle was 3,524 ft.-lbs. Because this load was slightly slower than the one above, I expected that the “drops” would be much more significant than they actually were. With a 300-yd. zero, the bullet would impact 31.6" low at 500 yds. (only 1.3" more) and 282.1" at 1,000 yds. (11.5" more). Remaining energy at 1,000 yds. is 1,062 ft.-lbs. In addition to being noticeably more pleasant on the shoulder, the H1000 load proved to be more accurate, too; in fact, it averaged 1.05" for 25 consecutive shots—impressive!

Do not exceed the propellant charges shown here. Out to 500 yds., the difference in “drops” between the slowest of the two loads above, 2686 f.p.s., and the 2850-f.p.s. velocity of the Mk 248 MOD 1 military load, is only 3.9"—certainly not worth pushing the envelope over. Even at 1,000 yds. the difference is an easily-compensated-for 35.6". Concerning wind deflection, in a 10-m.p.h., full-value wind the 220-gr. MatchKing deflects 13.8" (Mk 248 MOD 1), 14.7"(IMR-7828) and 15.1" (H1000), while at 1,000 yds. the numbers are 64", 68.2" and 70.1", respectively. Again, there are minimal differences between the three.

As you can see, the full potential of the .300 Win. Mag. is finally being realized—especially by our military snipers.

It’s little wonder, then, that Chris Kyle reported in his book, “I used a .300 Win Mag for most of my kills.”