Cast lead alloy and swaged lead bullets require a diameter about 0.001" greater than normal jacketed bullet diameter to shoot accurately and prevent cylinder throat and bore leading in revolvers. With revolvers of modern manufacture, that should work out to 0.358" diameter bullets for the .38 Spl. and .357 Mag., and 0.430" bullets for the .44 Spl. and .44 Mag.

Proper lead-bullet performance hinges on chamber throats not much larger in diameter than a barrel’s groove-to-groove diameter. For instance, Rim Rock Cowboy .44-cal. 200-gr. RNFP 0.430" bullets are a tight fit in the cylinder throats of my Smith & Wesson .44 Mag. revolver. No leading occurs with that combination at a slow velocity of 800 f.p.s. or fast 1200 f.p.s. Accuracy is comparable to 0.429" jacketed bullets.

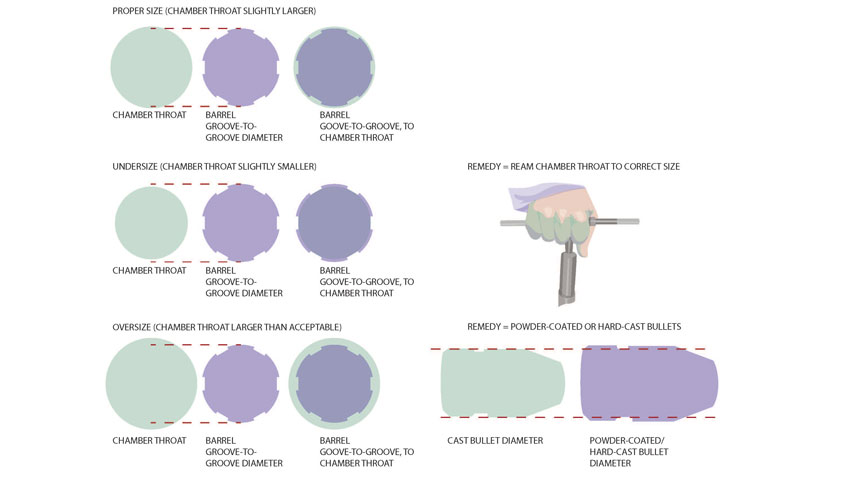

Those crucial dimensions can vary in revolvers. If cylinder throats are narrower than groove-to-groove diameter, leading is going to occur because the swaged-down bullets allow gas blow-by. A gunsmith can fix this by reaming cylinder throats to the proper diameter.

There are a couple remedies to prevent gas cutting and leading due to the chamber throat of a revolver’s chamber being excessively larger than bullet diameter. One is to use larger-diameter bullets that fit the throats. Some cast bullet companies offer the same bullet in several diameters. If you cast your own bullets you can cast with a harder alloy to slightly increase bullet diameter and use different diameter bullet sizer dies. I size 200-gr. flat-nose bullets in a 0.359" sizer die for a perfect fit in a Smith & Wesson 686 .357 Mag. Powder-coating also adds 0.002" to bullet diameter. Even hard-cast bullets are elastic, and bullets a few thousands of an inch over bore diameter do not raise pressures. The only limit is these larger bullets must seat in cases without bulging them. These bullets require a larger expander plug than normal in a case-sizing die, otherwise the bullets will be sized down when they are seated.

Some shooters shift to a harder alloy bullet in the belief it will prevent leading. This worsens the problem because incorrect bullet fit causes leading. Undersize bullets of a softer lead alloy may bump up in diameter on propellant ignition, filling chamber throats and preventing gas cutting. At lower pressures, the heel of hollow- or concave-base bullets can also expand to fill chamber throats.

Hopefully, your revolver accurately shoots cast and swaged lead bullets 0.001" larger in diameter than normal jacketed bullets. If not, these techniques will help, because the cost savings alone make lead bullets well worth the effort.

Additional Reading:

Back to Basics: Cast Bullets