This article was first published in American Rifleman, November 2002.

Few arms have served the U.S. military as long or as well as the famed “U.S. Rifle, Caliber .30, Model 1903.” Known as the “Springfield,” or simply the “’03,” to several generations of American servicemen and arms enthusiasts, the M1903 has gained an enviable reputation as one of the best bolt-action military rifles of all time. The M1903 was manufactured by Springfield Armory at varying levels of production from 1903 until the late 1930s and at Rock Island Arsenal from 1903 until 1913 and again from 1917 until just after World War I. Even though large numbers of M1917 “American Enfields” were manufactured and issued during World War I to supplement the supply of M1903s, the “Springfield ’03” remained the standard U.S. military service rifle until the adoption of the semi-automatic M1 “Garand” rifle in 1936. Even after adoption of the M1, however, the ’03 remained the primary American service rifle until production of the Garand could meet the demand.

Such was the situation at the beginning of World War II. The disaster at Dunkirk left the British in extremely perilous straits as thousands of badly needed rifles were abandoned in France when British troops were evacuated to England. Representatives of the British government turned to the United States for the acquisition of new arms. Several avenues were explored, including discussions with Remington Arms Company for the production of rifles under British contract. It was suggested that the old M1903 production tooling in storage at Rock Island Arsenal be used to produce rifles for the British. The U.S. War Department agreed to lease Remington the somewhat worn Rock Island ’03 manufacturing equipment and provided some 600,000 walnut rifle stock “blanks” also in storage. Remington agreed to pay for the stock blanks by manufacturing cartridges for the U.S. government under future contracts.

The British desired certain modifications, primarily related to modifications required to utilize the standard .303 British cartridge. Other changes included altering the stock (and muzzle) to allow use of the Lee-Enfield No. 4, Mark I bayonet and modifying the grip of the stock to mimic the “hook” type pistol-grip found on the Lee-Enfield. Some changes were fairly easy to accomplish, and others were more involved. The British were pressing for new rifles as soon as possible, and passage of Lend-Lease legislation opened up other avenues of arms procurement. Since the proposed Remington .303 rifles were no longer vitally needed, the British contracts were canceled in September 1941 before any rifles were manufactured.

The U.S. Ordnance Department immediately contracted with Remington for M1903 rifles in order to arm the rapidly expanding U.S. armed forces. The U.S. government ordered 134,000 M1903s from Remington the same day that the British contracts were canceled. By this time, Remington was ready to go into limited production of M1903s. The firm was assigned the serial number block of “3,000,000 to 3,599,999” for its initial production. Ten “trial production” M1903 rifles were produced soon after the contract was granted, and the first 1,273 production rifles were delivered in November 1941. These were initially to have been given the “M1903A1” designation, which would have required full pistol-grip (“Type C”) stocks. However, the large supply of stock blanks acquired by Remington were primarily suited for fabrication of the straight-grip type of stock, so the M1903 nomenclature was not changed. Interestingly, some internal Remington documents during this period refer to the rifles as “M1903 Modified.”

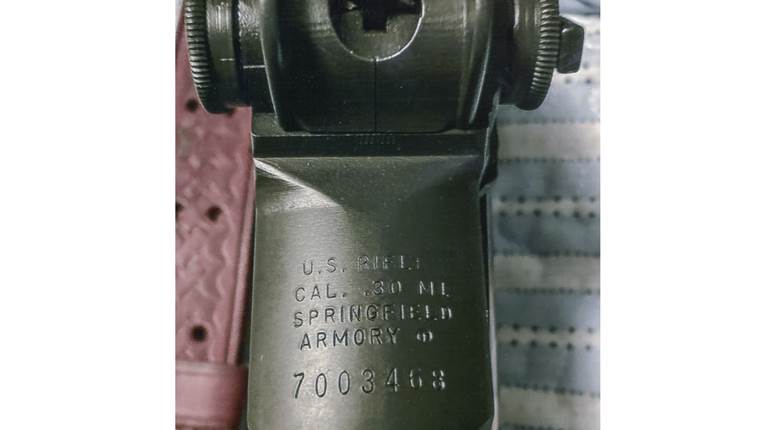

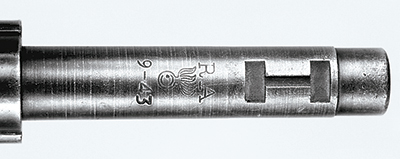

These early production Remington M1903s were very similar to the ’03s turned out by Rock Island late in World War I, including finely finished straight-grip (“Type S”) stocks with “grasping grooves” and handguards with a prominent sight-protecting “hump.” They were well-crafted, finished in black-tinted Parkerizing and utilized the same type of heat treatment as found on late production Springfield M1903s. The receiver rings of the new Remington ’03s were stamped “U.S./Remington/Model 1903/Serial No.,” and the barrels were marked “RA” (Remington Arms) in addition to the month and year of manufacture. The stocks were stamped with an Ordnance Department escutcheon (“crossed cannons”) and the initials “RLB” on the left side below the magazine cut-off recess. “RLB” represented Col. Roy L. Bowlin, Chief of the Rochester Ordnance District.

The attack on Pearl Harbor resulted in increased orders from the U.S. government for the Remington M1903s. The initial order for 134,000 was increased to 308,000 and again raised to 508,000, with a target production rate of 2,000 rifles per day. This huge increase in demand coupled with production problems stemming from use of the nearly worn-out Rock Island machinery resulted in something of a dilemma for Remington if the ambitious production schedules were to be met. Representatives from the Ordnance Department visited the factory and determined the company was spending too much time on unnecessary or cosmetic features of the rifles. The company was permitted to reduce the amount of metal polishing prior to finishing, reduce or eliminate unnecessary machining and to relax many non-critical tolerances. A gas escape hole was drilled into the left side of the receiver as had been done at Springfield Armory since 1936.

As Remington’s production continued, an increasing number of changes were made to the original specifications in the interest of reducing production time. Some of these changes were not readily apparent while others were quite noticeable—such as the elimination of the “lightening cuts” on both sides of the rear sight base, the elimination of the small gas escape hole on the right side of the receiver and the drilling of the rear guard screw hole completely through the receiver tang. Authorization was also granted to eliminate the “grasping grooves” on the stock and other features to reduce production time for the stock and handguard. The use of some stamped components to replace costly and time-consuming milled parts was also instituted. The stamped parts included the lower barrel band (and band spring), butt swivel, magazine follower and, eventually, a one-piece trigger guard/magazine assembly.

By the first quarter of 1942, the changes in the original specifications were sufficient to result in a rifle that was noticeably different from the early production Remington M1903s. The rifles with the changes were termed the “M1903 Modified” although, as stated, there is some indication that this term was in use as early as November 1941. In any event, the “M1903 Modified” designation has come into widespread use today to differentiate the Remingtons that incorporated the manufacturing modifications from the original, finely crafted ’03 rifles that were turned out during the first few months of production and will be used in this article to identify this variant from the earlier and later variants. It should be recognized that the production “shortcuts” were phased in over a period of time. Some of the earlier M1903 Modified rifles will have few stamped parts and later production will exhibit more stamped components.

Remington turned out M1903 and M1903 Modified rifles as fast as production permitted, and they saw use as training rifles and were used in combat fairly early in the war. Most of the early production Remington M1903s were diverted to military aid requirements similar to “Lend-Lease” for our Commonwealth allies, and many of these rifles were sent to New Zealand forces. It has been reported that a number of Remington M1903s were utilized by the U.S. Marine Corps in some of the early Pacific campaigns.

Even though the Remington ’03 rifles evidenced a number of manufacturing shortcuts, they possessed a strong action, and all of them are in the “high number” category.

M1903A3 Rifle

In early 1942, it was determined that production could be increased even more if the rear sight base and related parts could be dispensed with, as these components required a great deal of time-consuming machining. Remington engineers modified the basic design of the rifle by eliminating the M1905 pattern rear sight and replacing it with an adjustable peep sight mounted on the rear of the receiver. The handguard (now termed “barrel guard”) was lengthened to cover the gap between the receiver and the upper band of the rifle. The rear sight of the M1903A3 rifle was actually a better “battle sight” in many ways than M1905 pattern sight. In addition to the changes made in the rear sight, there was also more extensive use of stamped parts. The substantially modified rifle was standardized as the “U.S. Rifle, Cal. .30, Model of 1903A3” on May 21, 1942. Remington began deliveries of the new variant in December 1942. There was a period of time when the company manufactured the M1903 Modified and the M1903A3 variants concurrently. The last of the M1903 Modified rifles were turned out in May 1943.

The new rifle was marked “U.S./Remington/Model 03-A3/Serial No.” on the receiver ring. The “03-A3” designation was a bit unusual as it was essentially a colloquial term rather than the official nomenclature for the rifle. As with the preceding Remington ’03s, the barrel had the “RA” and “flaming bomb” markings as well as the month and year of production. The left side of the stock was stamped “FJA” (for Col. Frank J. Atwood), “RA” (Remington Arms) and the “crossed cannons” Ordnance Department escutcheon. A circled “P” proof mark was stamped on the grip behind the trigger guard, and various cryptic Remington internal inspection markings were stamped on the stock forward of the trigger guard. The stock furniture (one-piece upper band assembly, lower barrel band, band spring, sling swivel, buttplate and trigger housing/floorplate assembly) were constructed of stamped sheet metal.

The M1903A3’s stock was similar to the straight grip stock previously utilized with the M1903 Modified but was inletted to accept the “barrel guard ring” necessitated by the longer handguard. The ’03A3 stocks were also inletted for the M1905 sight as well. In addition to the straight grip stock, Remington also manufactured some stocks with semi-pistol grips, often dubbed “scant” or “scant grip” stocks today. The adoption of this pattern stock enabled Remington to utilize many of the stock blanks the firm had on hand from the abortive British rifle production contract. Most, if not all, of the “scant grip” stocks were utilized for replacement purposes, except for some that were used with M1903A4 sniper rifles (to be discussed later).

In October 1942, Remington was given permission to produce two-groove barrels for the M1903A3 as prior testing at the Aberdeen Proving Ground revealed that satisfactory accuracy could be obtained with them. Two-groove barrels resulted in reduced manufacturing time and cost which further boosted the ’03A3s production rate.

With the adoption of the ’03A3, simplification of the M1903 was taken as far as feasible without adversely affecting the accuracy, strength or efficiency of the rifle. The rather rough-hewn ’03A3 could be manufactured much faster and at a lower cost than the earlier rifles, yet boasted a strong action and a more efficient “combat sight” than its predecessors.

Remington received ever-increasing orders for ’03A3s, and the Ordnance Department sought an additional source. To this end, the Smith-Corona Typewriter Company was granted a contract for production of M1903A3s. The Smith-Corona ’03A3s were essentially identical to their Remington counterparts except for markings. Smith-Corona was eventually assigned two blocks of serial numbers. Smith-Corona did not use all of the numbers from the second block. The serial numbers used by the company went only into the 4,870,000 range. Remington only used a relatively few serial numbers from the final block, stopping at the very low 4,200,000 serial number range. There were also some serial numbers used for M1903A4 sniper rifle production from this final block as well.

Remington received ever-increasing orders for ’03A3s, and the Ordnance Department sought an additional source. To this end, the Smith-Corona Typewriter Company was granted a contract for production of M1903A3s. The Smith-Corona ’03A3s were essentially identical to their Remington counterparts except for markings. Smith-Corona was eventually assigned two blocks of serial numbers. Smith-Corona did not use all of the numbers from the second block. The serial numbers used by the company went only into the 4,870,000 range. Remington only used a relatively few serial numbers from the final block, stopping at the very low 4,200,000 serial number range. There were also some serial numbers used for M1903A4 sniper rifle production from this final block as well.

Remington (and Smith-Corona) turned out ever-increasing numbers of M1903A3s, and they provided valuable use for our rapidly expanding armed forces. Many of the rifles were utilized for training purposes “stateside,” but a number were shipped overseas for issue as supplemental service rifles. Although not used as combat rifles in extremely large numbers as compared to the M1903 or M1 Garand rifles, M1903A3s definitely saw combat use in several theaters of the war including the European and the China-Burma-India theaters.

M1903A4 Sniper Rifle

U.S. Army troops did not have a standardized sniper rifle in inventory at the time of the declaration of war, and there was increasing demand from overseas for sniper rifles. The demand for sniper rifles was too great to permit lengthy delays in developing a M1 Garand-based new arm, so the War Department contracted with Remington for a sniping version of the M1903 rifle. By this time, the ’03A3 was about to go into production, so the specifications were changed to develop a sniping version of this variant instead. In January 1943, the War Department contracted with Remington for 20,000 sniper rifles based on the M1903A3. The new rifle was designated “U.S. Rifle, Cal. .30, M1903A4, Sniper’s” and was basically a standard M1903A3 rifle without the front sight attached (although the milling cuts were present) fitted with a Redfield “Junior” mount screwed to the receiver ring and attached to the rear sight dovetail. Interestingly, the “’03-A3” nomenclature remained on the receiver ring of the new M1903A4 sniper rifle although this marking was applied to the extreme left of the receiver ring and the serial number stamped on the extreme right side which permitted both markings to be plainly visible with the Redfield mount in place.

As the M1903A4 was recently the subject of an article in these pages (“Making The Most of G.I. Marksmanship: The M1903A4,” January 2002, p. 56), the discussion here will be limited to the rifles themselves rather than the optics and mounts used on them. The’03A4’s bolt handle was concavely forged to provide clearance for telescopic sight, and the stock was inletted to accommodate the bolt handle. Early production M1903A4 rifles had four-groove barrels, but this was soon changed to two-groove barrels, and the bulk of them had the latter. Most ’03A4s had full pistol grip (“Type C”) stocks but, as stated, some were also delivered with the “scant grip” stock. The markings on the stocks were identical to those of M1903A3s of the same vintage, and the only real difference was the inletting for the concave bolt handle. Some of the “Type C” stocks were supplied by Springfield Armory (stamped “S” in the cut-off recess) and some later stocks were procured from the Keystone Company (stamped “K” in the same location).

Remington was initially assigned the serial number block of 3,407,088-3,427,087 for ’03A4 production. In June 1943, the Ordnance Department ordered an additional 8,365 ’03A4 rifles from Remington. The company was assigned the serial number block of 4,000,001-4,015,000 for the additional ’03A4 rifles. However, M1903A3 rifle production extended into this block of numbers and the M1903A4 rifles in this range had a “Z” prefix to the serial number in order to prevent duplicate numbers.

Remington ceased production of the M1903A3 in February 1944 and continued with M1903A4 production until June of the same year. By the time manufacture ceased, Remington had delivered 348,085 M1903 and M1903 Modified Rifles, 707,629 M1903A3 Rifles and 28,365 M1903A4 Rifles. (Smith-Corona manufactured an additional 233,998 ’03A3s).

Following the conclusion of World War II, large numbers of M1903s and M1903A3s were refurbished (overhauled) at a number of ordnance facilities. Many were subsequently sold via the auspices of the Director of Civilian Marksmanship (DCM) and given away to allied nations under various military aid programs. Recently, the Civilian Marksmanship Program obtained a sizeable quantity of M1903s, including a number of Remington M1903, M1903 Modified and M1903A3 rifles, and offered them for sale to qualified individuals.

While not used in large numbers during World War II as compared to the M1 Garand, the Remington rifles provided our armed forces with a badly needed source of reliable and serviceable military rifles. Many are not aware of the rifles of this type turned out by Remington during World War II. However, the Remington rifles were every bit as valuable and serviceable as the ’03s that were made by the government-owned and -operated entities of Springfield Armory or Rock Island Arsenal.