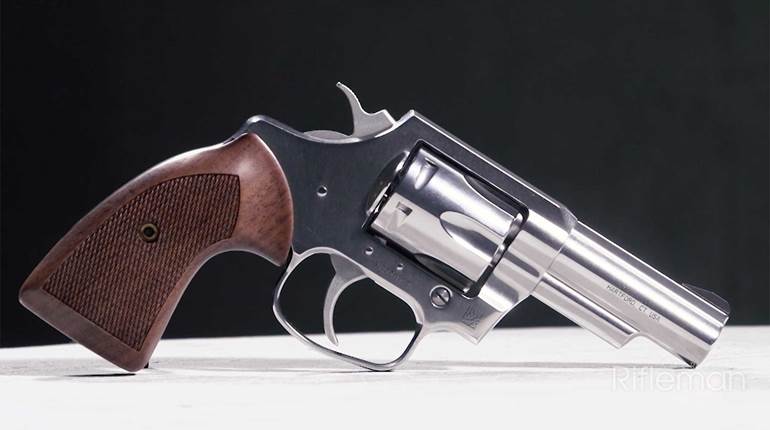

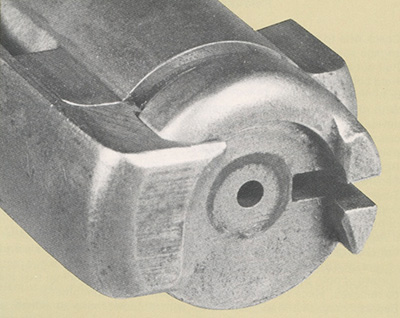

Even though this cutaway drawing is of a Mauser 98 sporting rifle with a double set trigger mechanism and a lever-style floorplate latch, it illustrates the design’s fundamental simplicity, suggests its inherent strength and reveals critical safety features.

When it comes to explaining the success of the Mauser Model 98 bolt-action rifle, one could simply attribute it to serendipity—it appeared at exactly the right moment in history and was good enough to get the job done. But that sort of notion requires a complete disregard for the historical narrative. In fact, German gun designer Peter Paul von Mauser—born June 27, 1838—toiled for more than three decades before his brilliance was fully realized in the bolt-action masterpiece that still bears his name a century-and-a-quarter later.

Late American Rifleman Technical Editor Ludwig Olson, widely regarded as the world’s foremost authority on Mauser rifles, wrote in the 1964 foreword to the Third Edition of his landmark work Mauser Bolt Rifles, “The Mauser bolt-action rifle was introduced slightly more than a century ago. Since that time, this famous rifle was improved in a succession of models and became the world’s most produced and popular shoulder arm. It enjoyed the greatest success in the role of a military rifle, being used by more than a score of nations in various parts of the world. While it has been superseded for military use by semi-automatic and automatic rifles, it still maintains great popularity as a sporting arm and is of considerable interest for collectors. Gunsmiths also hold the Mauser in high esteem, and the Mauser 98 has served as the foundation for many a fine custom sporter.”

Such testimony serves to recognize the Model 98’s place in history, yet doesn’t explain the reasons for its success. For that, we have to travel back to 1867, when Paul Mauser and his elder brother, Wilhelm, began work on what would become the Model 1871 Infantry Rifle.

History & A Theory

Paul, who had been drafted as an artilleryman and later was employed as a gunsmith at the Württemberg Royal Armory, eventually took inspiration from Nikolaus von Dreyse’s needle gun developed some 40 years earlier. Determined to improve the design, he retained the key turnbolt concept but improved it with a true firing pin that was self-cocked when the action was cycled. In 1872, Mauser’s rifle was formally adopted as the German Empire’s Infanterie-Gewehr 71. Featuring a wing safety and firing the 11.15x60 mm R blackpowder, metallic-case cartridge, the gun locked up by way of a bolt guide rib engaging the front of the receiver bridge. Originally a single-shot, the 1871 was improved with a tubular magazine in 1884, making the newly designated Model 71/84 a repeater. The Mauser brothers, Paul as inventor and Wilhelm as financial manager, had by 1874 acquired the armory—which, a decade later, would operate as Waffenfabrik Mauser. Their goal in the ensuing years became the development of a small-bore repeating bolt-action rifle that would be able to handle the higher-energy smokeless-powder cartridges. Unfortunately, Wilhelm Mauser died unexpectedly in January 1882, and the firm was unable to furnish a shooting example of a new rifle for testing by the Gewehr-Prüfungskommission (Rifle Testing Commission). Undeterred, the company found continued success selling military rifles to other countries, including the Model 89 Belgian and Model 91 Argentine, which used a box magazine fed by stripper clips and were chambered for the rimless 7.65x53 mm cartridge.

Subsequent incremental improvements to the Mauser 90-series rifles were driven by military contract requirements and, no doubt, by Paul Mauser’s seemingly relentless pursuit of the ideal action. The signature non-rotating claw extractor was introduced in the 1892 model. The Model 1893, or Spanish Mauser, included a shorter magazine containing the cartridges in a staggered column, which allowed for a trimmer, more durable rifle. The Model 1895 had a shoulder at the rear of the receiver to engage the root of the bolt handle, offering extra protection in the event the bolt lugs failed and was the first rifle chambered in the 7x57 mm Mauser cartridge. Then, the following year, as the result of a contract with the Swedish military, the Model 96 added gas-escape holes and an integral guide rib on the bolt body. All of the aforementioned improvements set the stage for the Model 98, which was chambered in 7.92x57 mm Mauser, or what Americans now refer to as 8 mm Mauser—and which provided inspiration for our own line of legacy .30-cal. cartridges.

Olson noted the various incremental changes in a checklist that validated the Model 98’s benchmark status. “Principal improvements over previous Mauser standard rifles produced in large quantity were cocking on opening of the bolt, shorter firing pin travel (only 1/2") and therefore faster lock time, extra large gas escape holes in the bolt, enlarged-diameter receiver ring for added strength at a vital point, locking screws to prevent the guard screws from vibrating loose, and a bolt sleeve lock. Also included were the full-depth thumb cut in the left wall of the receiver, guide rib on the bolt (first used in the Swedish Mauser), a safety lug, shrouded bolt head, gas shield on the bolt sleeve, and the undercut extractor (introduced with the German Model 96 experimental).”

The German commission was apparently pleased as, on April 5, 1898, it formally adopted the rifle for its military as the Gewehr 98, which, just 16 years later, would see combat in the First World War. By then, Mauser bolt-actions had already become praised as significant advances in combat rifle technology, including by such figures as Afrikaner-American farmer and military general Benjamin Johannes Viljoen who, during the Second Boer War, reportedly remarked that he put trust only in “God and the Mauser.” After the Great War erupted in 1914, an oft-repeated tale attributed variously to officers of opposing sides suggested that in issuing troops the Short, Magazine Lee Enfield (SMLE), the Model 1903 Springfield and the Gewehr 98, the British, the Americans and the Germans had fielded a battle rifle, a target rifle and a hunting rifle, respectively. Such commentary suggests that the Enfield’s capacity and speed of operation, the Springfield’s excellent sights and trigger, and the Mauser’s controlled-round feed and general reliability were their salient attributes. Of course, it is well-known that the ’03 Springfield’s design borrowed so heavily from that of the Mauser 98 that the U.S. Army decided it should settle with Mauser financially to avoid a patent-infringement claim. Clever declarations and litigation trivia aside, however, the Gewehr 98 would go on to acquit itself quite well during the Great War as a combat arm and, in revised form as the shorter, lighter Karabiner 98k, would serve as the frontline arm for Germany throughout World War II.

As we’ve already seen, though, the result of Mauser’s efforts had not been accomplished overnight. His journey as a gun designer was dictated by the manufacturing processes of his day, and in the mid-19th century, that typically involved building firearm components from hot drop forgings, pounded out on massive mechanized hammers and machined to final shape on mills or lathes one operation at a time before being hand-filed to achieve proper function. It was an approach that made sense in an era when a man’s time was not worth nearly as much as his skill. Yet, even today, the Mauser 98 design—especially in its “large-ring” iteration, which is the focus here—represents a standard for bolt-actions that has, arguably, never been eclipsed. So, the question remains: What makes the Mauser Model 98 so enduring?

I suggest that the answer lies in a relatively straightforward formula based on equal measures of three fundamental design characteristics: simplicity, strength and safety. And, like all such perfectly balanced “tripods,” if any one leg is deficient, the whole structure collapses rather abruptly.

A Simple Action

As is often the case in mechanical engineering, the less complicated a mechanism, the less prone it is to failure. In design and operation, the Mauser 98 is a paragon of simplicity—despite the fact that it was the result of numerous complex manufacturing steps. The entire Gewehr 98 rifle consisted of a scant 44 parts, with the action, sans stock and barrel components, accounting for a mere 29 (the bolt assembly itself contained only nine). By comparison, the SMLE had 67 parts total and 32 in the action, and the 1903 Springfield had 49 total and 34 in the action.

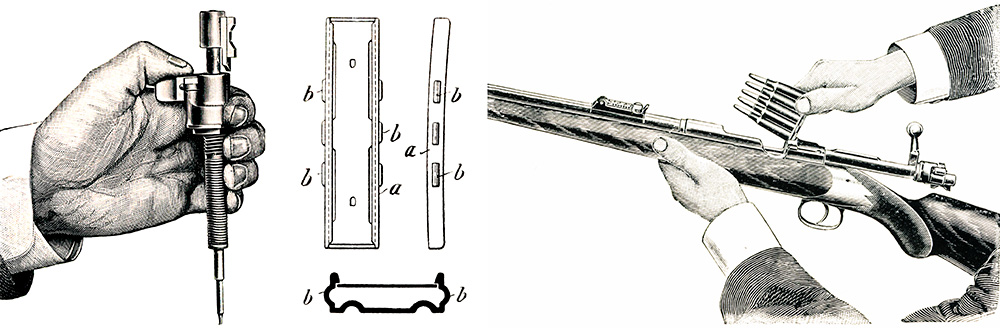

The Model 98’s basic turnbolt mechanism, reminiscent of that of an ordinary deadbolt door latch, was about as straightforward as possible. The flat-bottomed receiver incorporated the locking lugs, bolt raceways, barrel threads, recoil lug and magazine rails. Early versions featured a bolt handle that extended directly out to the right side when the action was locked. And because it lay on a plane perpendicular to the locking lugs, a 90-degree counterclockwise rotation freed them from their recesses at the 12-o’clock and 6-o’clock positions in the receiver ring. When the bolt was retracted, the non-rotating extractor, which rode alongside it above the right receiver wall, withdrew the fired case or live cartridge that was within the grasp of its hooked front end from the moment it was pushed free of the magazine.

The mechanism was designed with enough material in key wear areas so as to resist failure. And the more aggressively its bolt was manipulated, the more smoothly and positively the cycle of operation occurred. Cocking of the robust striker spring was accomplished mostly on opening of the action wherein a 45-degree camming surface at the rear of the receiver bridge engages the root of the bolt handle as it is rotated upward. The firing pin itself was of a single piece of steel. Withdrawing the bolt slightly more than 4½" extracted a spent case or full cartridge and, toward the end of its travel, moved past a spring-loaded, blade-type ejector to expel it. As the next round in the magazine rose into position, and the bolt returned forward, its undercut face allowed the cartridge rim to slide under the extractor’s hook prior to the round being chambered.

The staggered-column magazine was entirely internal and, therefore, impossible to lose or misplace, and while the Model 98 was designed to be fed from a light, simple and inexpensive five-round stripper clip by way of a slot in its receiver bridge, it could also be loaded one round at a time simply by pushing cartridges down into the open action. A clearance notch in the left receiver wall allowed the loading hand’s thumb to press cartridges held in a clip fully into the magazine. Then, simply closing the bolt popped the clip free of the gun as the first round was chambered.

The trigger guard/magazine assembly served multiple duties; it anchored the action in the stock by way of two stout machine screws that, in military actions, were typically locked in place by capture screws, and it retained the floorplate, which secures the bottom of the magazine spring. The floorplate also featured a recessed plunger at its rear that could be depressed by the bullet tip of a cartridge, allowing it to be slid rearward. That freed the magazine spring and follower, and any cartridges still in the magazine, from the gun.

Removing the bolt from the action for cleaning or service required only hinging the bolt stop away from the receiver at the left rear of the action. The bolt assembly could then be cleaned and, if necessary, repaired without the use of tools after depressing a small spring-loaded plunger on its sleeve and unscrewing it from the bolt’s rear.

A Strong Action

The Mauser’s simple design and quality all-forged-steel manufacture lent it a strength that easily exceeded its mechanical requirements. Its flat-bottomed receiver was pounded out in a single piece, and its integral recoil lug, which measured more than 1" in width and 0.25" in depth, made for secure seating—either into a wooden military stock with an embedded crossbolt or, in later years, into synthetic stocks form-fit using bedding compounds—once the action screws were tightened.

The bolt, bolt handle and knob were, likewise, forged and machined from a single piece of steel. The bolt’s two relatively large primary locking lugs, located at its front and horizontally opposed, and its safety lug, were machined integrally with the body. The location of the main locking lugs greatly reduced the tendency of its body to stretch under firing forces, which also minimized cartridge case elongation. According to the late gunsmith and author Jerry Kuhnhausen, “History has demonstrated that Mauser bolt actions are tough, dependable and extremely durable,” although he also set forth a litany of warnings regarding variations in heat treatment and steel quality depending on the country of origin and timeframe of manufacture. But the steels used in pre-war and commercial German Mausers, and in later examples by such reputable firms as Fabrique Nationale, were of high quality and were rendered sufficiently malleable through heat treatment so as to respond properly to firing forces. Surfaces were carburized, or casehardened, in order to reduce wear. In contrast to some components used in the construction of modern bolt-action rifles, no light alloys or polymers were used to build traditional Model 98 Mausers. Even when the exigencies of wartime production prompted time- and cost-cutting measures in rifles using the Model 98 action, its fundamentally sound design meant it was still likely to hold up to all but extraordinary stresses.

Specific dimensions and features designed into the large-ring Model 98 action—having a receiver ring diameter of 1.41" and with an internal collar against which the barrel abuts—were overbuilt, making failures even under battle conditions uncommon. The point was emphasized by the late American Rifleman contributor Frank de Haas in his classic book Bolt Action Rifles: “Because the large-ring action has a thicker wall of metal surrounding the sides and top of the barrel shank and locking lug recess areas, it naturally is stronger than the small-ring action.” Even small parts of the action were relatively stout by commercial firearm standards. The result of all that steel was a complete action, sans stock, barrel and sights, that weighed in right at 3 lbs. Of course, such construction meant that Mauser 98-based rifles did not gain a reputation as lightweights—especially by today’s standards—a fact that has always them at somewhat of a disadvantage for consideration as modern mountain or scout rifles.

The massive, non-rotating “claw” extractor may be the Model 98’s most distinctive feature and is responsible for its characteristic “controlled-round feed” of cartridges—an advantage that, early on, earned it the trust of soldiers and, later, near reverence from hunters of dangerous game. In essence a massive spring, the extractor is retained by a simple collar that fits into an annular groove machined into the bolt body.

According to de Haas, who had extensive hands-on experience with numerous bolt-actions, “Without question, the M98 Mauser is the best, strongest and most foolproof military turnbolt action ever made.” Despite that definitive assessment, however, the author and gunsmith lamented that the Model 98’s aforementioned thumb notch in its left receiver wall was a potentially significant weak point.

A Safe Action

Mauser understood that he was building a soldier’s rifle, and he knew all too well that such an arm had to not only withstand the rigors of battlefield conditions, but that its rapid operation had to be foolproof in the heat of combat and absolutely must not pose a danger to its user.

When the bolt is locked into battery, its primary lugs engage recesses in the receiver itself, but firing forces do not directly bear on the somewhat smaller safety lug located at its rear. Instead, that lug, which is there simply as a backup in case of a catastrophic cartridge failure, rotates into an oversize recess in the lower portion of the receiver. The firing pin has shoulders that ensure it cannot contact the primer of a chambered cartridge until the bolt is locked into position, preventing an out-of-battery detonation.

In addition to mechanical features designed to ensure safe operation, Mauser also placed greater emphasis on gas handling in the Model 98 design than in any of his previous models. In the event of a pierced primer, case-head separation or other catastrophic failure, two large ports positioned in the bolt body’s underside on either side of the extractor collar align with the locking lug raceway on the receiver’s left side when the bolt is in battery, providing an escape route that leads rearward and then through the thumb notch. Again, one of de Haas’ few complaints about the Model 98 was that a simple round hole in the left side of the receiver ring would have further re-directed such harmful gases. Additionally, a flange at the bolt sleeve’s front serves to shield the shooter’s face from any errant propellant gases that might escape the otherwise well-vented action.

The safety mechanism itself was also simple in design and, importantly, intuitive in operation. Its three positions—pointing left to fire, straight up to engage the firing pin yet allow for operation of the bolt and right to lock both the firing pin and bolt—allowed for any possible manipulation of the action that was necessary with complete confidence. In the central position, it obscured the sights, reminding a harried user that he must flip it off to the left in order to fire. It is a movement that, if initiated while resting the firing-hand thumb against the safety, can be practiced so as to become virtually automatic when the gun is brought to the shoulder.

To this day, three characteristics of true Mauser Model 98 military actions ensure predictable, safe handling—albeit with a rifle pointed in a safe direction: Rounds can be removed from the magazine simply by running the bolt forward and rearward without locking the handle. Also, should the user wish to de-cock the action of a fully cleared rifle before closing it and after the trigger has been released, with the safety still in the left-most, or “fire,” position, simply open the action, pull back the bolt and then hold the trigger back before running the bolt forward again. Finally, remember that the geometry of the extractor means that proper chambering of a cartridge can only be accomplished by having it feed out of the magazine—but don’t assume that a particular rifle hasn’t been modified to allow for the extractor to snap over a cartridge.

Ironically, Paul Mauser lost his left eye in a rifle-testing incident three years after the Model 98 was accepted by the German military. After having developed perhaps the safest bolt-action rifle in the world, the accident occurred as he was testing the C98 self-loading design. Then, on May 29, 1914, he died at age 74, just two months before his namesake rifle would see combat in the hands of his countrymen at the start of World War I.

An Enduring Legacy

The Model 98 design undoubtedly influenced several of the most successful commercial American bolt-actions of the post-World War II era—most notably the pre-’64 and Classic Winchester Model 70 and the Ruger M77. And, along with Mauser itself, a variety of commercial firms have offered bespoke-quality Model 98-based sporting rifles throughout the years, including John H. Rigby & Co. of London and Griffin & Howe of New York. Chamberings have included cartridges much larger than those originally intended for the military Model 98—a further testimony to its sound design.

Today, long after the post-World War II military rifle sporterizing wave has crested, owners of original-condition surplus Mausers are more inclined to preserve them in collections rather than re-purpose them into hunting arms. But some actions still find their way into the hands of artisans, such as those in the American Custom Gunmakers Guild, who transform them into exquisite yet functional examples of firearm art. And although latent demand for newly manufactured examples of true Mauser 98 actions results in limited production, offerings can easily command five-figure prices.

Also, and somewhat counterintuitively, modern manufacturers with multi-axis CNC-machining capabilities have mostly chosen to go in entirely different directions from the somewhat-intricate component shapes dictated by the Model 98’s design, typically drawing up bolt-actions based on round cross section, or tubular, receivers, and featuring so-called “full-diameter” bolt bodies that preclude the need for raceways being cut into the receiver’s interior. Bolt handles are typically formed from separate components joined together by way of screw threads, dovetails or brazing—unless they are made using investment casting. And full-length claw extractors are rarely encountered in modern actions, manufacturers instead preferring simple spring clips, sliding plates or smaller pivoting hooks. In fact, controlled-round feed designs, in general, are in the minority.

Still, that Paul Mauser’s Model 98 was far more than simply “good enough” for its time is generally agreed upon by students of firearm technology. The intentional nature of its design resulted in predictable operation, which made it dependable for the most demanding and neglectful of soldiers in the past and earned it praise from the most discriminating and fastidious hunters and shooters in more modern times. While there are more and more bolt-action rifles on the market today that are lighter and less expensive, none carry the cachet or can boast the reputation for durability and unfailing reliability of the Mauser 98. That it represents the ultimate example of the gun designer’s art in bolt-action mechanisms may still be argued by some, but regardless of where, or in whose hands it is found, a Mauser 98-action rifle will always be a supremely dependable tool and a pleasure to use.

In the annals of firearm history, the Mauser 98 will likely always remain truly great.

Note: Three excellent books served as resources for the foregoing: Mauser Bolt Rifles by Ludwig Olson (brownells.com); Bolt-Action Rifles by Frank de Haas (amazon.com); and The Mauser Bolt Actions, M91 Through M98, A Shop Manual, by Jerry Kuhnhausen (gunbooks.com).