"Innovation distinguishes between a leader and a follower,” believed the late Steven Paul “Steve” Jobs, co-founder, chairman and CEO of Apple, Inc. It’s obvious that Nosler, Inc., subscribes to this philosophy as well; since 2014, the year that the 26 Nosler made its debut, the Bend, Ore., company has introduced a total of five new cartridges. Outside of the early 2000s, when Winchester and Remington were embroiled in a frenzied ballistics battle, such a flurry of activity is somewhat unusual—makers of proprietary and wildcat cartridges notwithstanding, of course. Of the new Nosler namesakes, the .22 caliber is arguably the most innovative.

The Million-Dollar Question: Why?

Everything has a purpose ... or at least it should. According to company literature, Nosler’s objective in designing the 22 Nosler was to create the “most powerful .22-cal. cartridge that would reliably function in the AR platform.” Read “most powerful” as “fastest”—velocity and energy are interrelated.

Mandating that the new cartridge reliably function in the AR-15 made the omnipresent .223 Rem. and 5.56x45 mm NATO cartridges benchmarks for performance. In other words, the goal was appreciable velocity gains over these stalwarts. Frankly, the realm was ripe for the picking; despite Internet forums abuzz with AR-15 enthusiasts clamoring for a cartridge with ballistics akin to the .22-250 Rem., nothing like that existed. Nosler seized the day.

Convenience was also an important consideration in developing the cartridge. The company wanted converting an AR in .223 Rem./5.56x45 mm NATO to 22 Nosler to be an uncomplicated process.

Behind The Design

Unlike its brethren—the 26, 28, 30 and 33 Nosler cartridges—which are parented by the antiquated .404 Jeffrey, the 22 Nosler’s case is unique; it’s not derived from the similarly sized 6.8 mm SPC and, thus, brass cannot be created from such. The case, which measures 1.760" in length (the same as the .223 Rem.), tapers from 0.420" at the extractor groove to 0.400" at the shoulder. Due to its increased girth (when compared to the .223 Rem., which measures 0.378" and 0.354" at the same points, respectively), the 22 Nosler has an appreciably more capacious case.

According to Zach Waterman, Nosler’s public relations manager, case capacity is 36.0 grs. of water at overflow and 33.0 grs. with a 55-gr. Ballistic Tip seated to give a cartridge overall length (C.O.L.) of 2.260". By comparison, the .223 Rem. holds 27.4 grs. of water when the same bullet and C.O.L. are utilized. Waterman reported that .223 Rem. brass holds 31.0 grs. of water at overflow. A five-grain difference is noteworthy.

Supplemental case volume offers several benefits. First, there’s extra room for propellant, which permits higher velocities. With an increase in velocity comes a flatter trajectory and less wind deflection—boons to varmint hunters and competitors alike—all while boosting on-target energy levels. Second, long-for-caliber projectiles, which are typical of those used in High Power Rifle competition, occupy considerable propellant space when seated to a cartridge’s SAAMI-standardized maximum C.O.L. For example, Nosler’s .22-cal., 77-gr. HPBT Custom Competition (CC) bullet measures 0.980". When seated to the maximum C.O.L. of 2.260" (in either the 22 Nosler or the .223 Rem.), 0.480" of the bullet protrudes into the case. As you’ll see shortly, the 22 Nosler is less affected.

Of course, there is the downside that, due to the larger circumference of the 22 Nosler’s case, it cannot be used in .223 Rem./5.56x45 mm NATO magazines. Instead, 6.8 mm SPC magazines are employed.

The 22 Nosler’s 30-degree shoulder (the .223 Rem. has a 23-degree shoulder) begins at 1.389", as opposed to the .223 Remington’s 1.438". This prevents the latter from chambering in a gun designed for the former. A longer-than-caliber neck is a byproduct; at 0.245" in length, the 22 Nosler’s neck is 0.042" longer than that of the .223 Rem.

As with the .223 Rem., the 22 Nosler has a rebated rim measuring 0.378" in diameter, so no modification to the standard AR bolt is necessary. Simply change the barrel or upper receiver to 22 Nosler and you’re good to go (for another option, see the sidebar on p. 52). Lastly, because of the 22 Nosler’s design, case stretching will be minimal, which should assure long reloading life.

The 22 Nosler is a SAAMI-approved and -standardized cartridge. Like the .223 Rem., maximum average pressure (M.A.P.) is set at 55,000 p.s.i. Keep in mind that, although the existing gas block of your .223 Rem./5.56x45 mm NATO-chambered AR will work with the 22 Nosler, due to higher gas volume (i.e. increased charge weights), Nosler recommends an adjustable gas block.

Making Comparisons

A degree in engineering physics isn’t needed to realize that, when the 22 Nosler and .223 Rem. are standing side-by-side, the former will significantly outperform the latter. But, the proof is in the pudding, right?

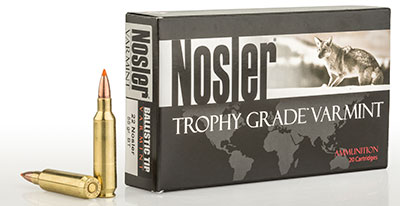

Only three factory 22 Nosler loads were available as this was written: Varmageddon 62-gr. FBHP, Trophy Grade Varmint 55-gr. Ballistic Tip (BT) and Match Grade 77-gr. HPBT CC. Listed velocities for each load from the 18" barrel of an AR are as follows: Varmageddon, 3100 f.p.s.; Trophy Grade Varmint, 3350 f.p.s.; and Match Grade, 2950 f.p.s. Nosler doesn’t have a comparable .223 Rem. load in the Trophy Grade Varmint line, but one is available in the Varmageddon series. Loaded with a 55-gr. tipped projectile—albeit flat base in design—it attains 3100 f.p.s.—the same velocity, but with a bullet weighing 11 percent less than that of the 22 Nosler load. Using Nosler data, from an 18" barrel the differences in drop between the two at 300, 400 and 500 yds. are 1.4", 4.4" and 9.7", respectively. The differences would mount even further if using muzzle velocities from Nosler’s 24" test barrel, which are 3500 f.p.s. for the Trophy Grade Varmint load and 3100 f.p.s. for the Match Grade load.

When loaded with the same 77-gr. BTHP CC bullet, how does the .223 Rem. compare to the 22 Nosler? Not favorably, since the lengthy projectile occupies considerable propellant space, which enables it to attain only 2550 f.p.s.—400 f.p.s. slower than the 22 Nosler. Again, using Nosler’s numbers, from the 18" barrel of a 22 Nosler-chambered AR, at 300, 400 and 500 yds., the 77-gr. pill drops 3.1", 9.0" and 18.7" less than when propelled by the .223 Rem. Wind deflection is reduced by 2.2", 4.1" and 6.8" at the same distances. Finally, whereas the 22 Nosler adds 154 ft.-lbs. of punch to that of the .223 Rem. at 500 yds. (i.e. a total of 515 ft.-lbs.) from the 18" barrel, it increases by 220 ft.-lbs. when expelled from a 24" 22 Nosler barrel.

Is the 22 Nosler comparable to the .22-250 Rem.? Let’s see. Nosler’s Trophy Grade Varmint line has a .22-250 Rem. load featuring a 55-gr. BT pushed to 3500 f.p.s. (from a 24" barrel). From an 18", 22 Nosler-chambered barrel the same projectile hits 3350 f.p.s.—200 f.p.s. slower—but is within 50 f.p.s. when fired from a 24" barrel. For all intents and purposes, that’s virtually identical. And when handloading (see sidebar), similar numbers can be achieved using several grains less propellant, though the greater case capacity—approximately 43 grs. of water—of the .22-250 Rem. permits notably higher velocities through handloading and certain factory loads.

Innovation Or Illusion?

“That’s the real deal,” reported an ardent shooter—and .22-250 Rem. devotee—referring to the 22 Nosler after having sent five rounds of Match Grade 77-gr. BTHP CC load downrange from the Nosler Varmageddon AR (by Noveske) topped with a Leupold VX-3 8.5-25X 50 mm scope. I concur. Several range sessions have shown that stellar accuracy and ballistics are attainable with the 22 Nosler. When using the Trophy Grade Varmint 55-gr. BT load, five consecutive, five-shot groups averaged 1.05" at 100 yds. from a Caldwell 7-Rest. From the 18", 1:8"-twist barrel, the Match Grade 77-gr. BTHP CC load had a mean of 0.88". The smallest group recorded with factory ammunition was 0.65". Unsurprisingly, handloads posted better averages than did the factory loads (see the sidebar above). Recovered cases showed ejector hole markings and other scarring of the bases, along with flattened primers. A raised line on the bolt face was partially to blame, and pressure and/or brass softness contributed to the other characteristics.

Given the cartridge’s high velocities, barrel heating occurred quickly—even on a 53° F day. Correlated with barrel warming was dispersion of bullet impacts. Typically, the first three or four rounds clustered startlingly close together, only for the group’s size to increase with the fifth shot. Total cooling, however, cannot be expected on a prairie dog shoot, either. As to velocities, the 55-gr. BT load averaged 3432 f.p.s. for 10 consecutive shots, and the 77-gr. BTHP CC had a mean of 2928 f.p.s. Standard deviations were 22 and 17, respectively.

Final Thoughts

Nosler achieved its goal with the 22 Nosler. The cartridge is ballistically superior to the .223 Rem. and 5.56x45 mm NATO in all measures—trajectory, wind deflection and on-target energy. Long-range varminters, as well as those who use an AR in .223 Rem. for whitetail deer and feral hog hunting, will benefit greatly. So too will competitive shooters. I can foresee the 22 Nosler appearing on the firing lines at National Matches in the not-too-distant future.

From a 24" barrel, the 22 Nosler is capable of .22-250 Rem.-like performance—without the headaches associated with the latter. But, it’s not a .22-250 Rem., and it wasn’t meant to be. In addition to efficiency, a consideration for the high-volume shooter, the 22 Nosler’s case design reduces stretching and thus trimming, keeping you in the field and on the range longer. The same cannot be said about the .22-250 Rem. With regard to barrel life, Nosler reports, “One should see approximately 2,000 rounds as used in competition and as many as 4,000 rounds if used as a plinking rifle.” Depending on the source, this is somewhat better than the .22-250 Rem.

Cost and availability are always considerations. Currently, only Nosler sells 22 Nosler ammunition and component brass. Moreover, using Nosler ammunition for comparison sake, on nosler.com Trophy Grade Varmint 22 Nosler ammunition sells for $3.05 more per box than .22-250 Rem. and $5.55 more per box than .223 Rem. In the Varmageddon series, however, 50-count boxes of 62-gr. HPBT 22 Nosler sells for $41.95—a real value. The primary challenge for the 22 Nosler is the low cost, diversity and availability of .223 Rem. and 5.56x45 mm NATO ammunition. Hopefully, more manufacturers will step up and bring costs down.

Nosler will be marketing several guns in 22 Nosler, including: Varmageddon AR (by Noveske), M48 Liberty, Heritage and Custom. Other rifle makers on board include: Colt Competition/Bold Ideas, Midway/Bear Creek Arsenal, AXTS/Radian, War Sport, Barrett, NorthTec Defense, Noveske, Proof Research and X-Caliber. Now there just needs to be a value-priced bolt-action.

“If at first the idea is not absurd, then there is no hope for it.” Commonly attributed to Albert Einstein, the quote is fitting for the 22 Nosler. At first it appears to be frivolous; however, in time you’ll recognize the innovative nature of its design. I did. That’s why there’s hope for the cartridge. It’s also further evidence that Nosler is a leader, not a follower.

Handloading The 22 Nosler

Shooters looking for more options in 22 Nosler loads than are offered by the company can find handloading recipes at load-data.nosler.com for bullets ranging in weight from 40 to 77 grs., which should fulfill the majority of their needs. Bullet options in this range would fill volumes.

RCBS and Redding are producing a variety of dies for the cartridge, including two- and three-die sets encompassing everything from “National Match” and “Master Hunter” to “AR-Series Small Base.” That it’s a SAAMI-approved and -standardized cartridge has obviously hastened the development process—a good thing.

Reloading the 22 Nosler is relatively straightforward; however, there are caveats. If loading for an AR-type arm, full-length sizing is recommended; using a die that resizes to minimum dimensions, such as the RCBS AR-Series Small-Base, is even better. Through full-length sizing, smooth functioning is assured. When handloading for this article, I used the standard two-die set (No. 80768) from Redding. The results speak for themselves.

When seating bullets with a cannelure for a semi-automatic rifle, a roll crimp is recommended. Should there be no cannelure, a taper crimp is suggested. A taper-crimp die is part of most premium three-die sets. Be mindful of cartridge overall length; exceeding cartridge overall length (i.e. 2.260") will cause magazine issues.

According to Nosler, top velocities for 40- and 50/52-gr. bullets will be found with H4985, while CFE-223 is the go-to for 55- and 64-gr. projectiles. The company reports that Hodgdon BL-C2 propels 69/70-gr. bullets upward of 3159 f.p.s., and with Hodgdon H380, the 77-gr. HPBT CC hits 2981 f.p.s. Some of the other top propellants are: Hodgdon Varget, Ramshot TAC, Accurate 2520, Reloder 15 and Norma 202.

Cases are currently manufactured only by Nosler. Available in 100-count boxes, these ready-to-load, premium cases sell for $67 (midwayusa.com). Lastly, the 22 Nosler uses small rifle primers for ignition. The company used Winchester Small Rifle (WSR) for load development.

Using the abovementioned primer and 55-gr. Nosler Ballistic Tip bullets, I assembled loads using two different propellants: Hodgdon CFE-223 and Varget. Incremental changes with the former resulted in nearly all charges grouping tightly. Settling on the maximum charge of 33.0 grs. of CFE-223, five consecutive, five-shot groups averaged 0.83". Velocity from the Varmageddon AR was 3297 f.p.s.

A second load, also with the same primer and projectile, featured 29.3 grs. of Hodgdon Varget. For 25 consecutive shots the mean was 0.85"; however, this load produced the single smallest group of the day—0.53". Velocity was 3058 f.p.s.

Lastly, I loaded 40- and 77-gr. bullets with Nosler’s maximum noted charges of H4895 and H380, respectively, to see what the top velocities would be. The 40-gr. projectile attained 3767 f.p.s., while the 77-gr. bullet hit 2908 f.p.s. (only 73 f.p.s. slower than when fired from a 24" barrel). Measured cases showed minimal stretch.

Given the results above, I can only imagine what the 22 Nosler is capable of when finding the perfect primer, projectile and propellant combination. It’s a handloader’s dream.

—Aaron Carter

The Third Option: Convert Your .223 Rem. AR To 22 Nosler

While it’s easy enough to add a new upper to your existing AR, or even replace the barrel, there is a third way to have one chambered for 22 Nosler.

Existing .223 Rem./5.56x45 mm NATO rifles can be converted to 22 Nosler. It’s a gunsmithing project that requires some time on a lathe, but it’s not horribly complicated and will probably be less expensive than either of the other two options.

It’s more than just running a reamer in to make a new chamber, though. The case lengths of the 22 Nosler and the .223 Rem. are the same at 1.760", however, the length from the base to the minimum headspace dimension on the shoulder is shorter on the 22 Nosler at 1.450", while the .223 Rem. is 1.4636". The reason is simple, if they were the same length, or the Nosler cartridge was longer than the .223 Rem., a .223 Rem. cartridge would chamber in a 22 Nosler firearm. This creates a very dangerous situation if the cartridge were to fire.

Because of this, the barrel must be set back so the chamber will clean up at the shoulder with a 22 Nosler reamer. In this case it must be set back the depth of one barrel thread so that the gas port will orient correctly at top-dead-center, under the gas block.

The barrel extension must be removed from the barrel. The barrel is dialed in and centered in a four-jaw chuck. The shoulder is cut back the depth of one thread. The threaded shank on the barrel must also be shortened by the same amount.

The next step is to cut the 22 Nosler chamber to the proper headspacing. A taper is added to the back of the barrel and the barrel extension is re-installed and torqued to 150 ft.-lbs. Simple enough right? In theory anyway.

My reamer is from Dave Manson Precision Reamers (mansonreamers.com), and he cautions that this is a tricky bit of machining because the existing chamber will keep the reamer from being supported by the pilot at the start of the cut. With the unguided reamer, care must be taken to avoid chatter. Manson said the key to avoiding chatter is to use an aggressive feed rate to keep the reamer loaded. I, of course heeded that advice after first taking a cautious approach. I experienced severe chatter in the chamber, but was able to correct it using the cleaning patch technique explained on Manson’s website.

There is one last thing that needs attention. With the existing gas port, the gun will likely be overgassed with the increased volume of the 22 Nosler. Mike Lake is the company's senior manager for engineering, research and development, and he is the guy responsible for the 22 Nosler cartridge. He noted that: “Most standard .223 gas ports are around 0.090" in diameter. With the 22 Nosler, we have had good luck using a 0.078" port and a rifle-length gas system.”

If you are using an existing barrel with a larger 0.090" port, the solution is an adjustable gas block. They are available from Brownells (brownells.com) in a wide range of designs and prices. Adjust the gas volume until the bolt locks back reliably on an empty magazine and the brass ejection pattern is at about 2 o’clock.

—Bryce M. Towsley