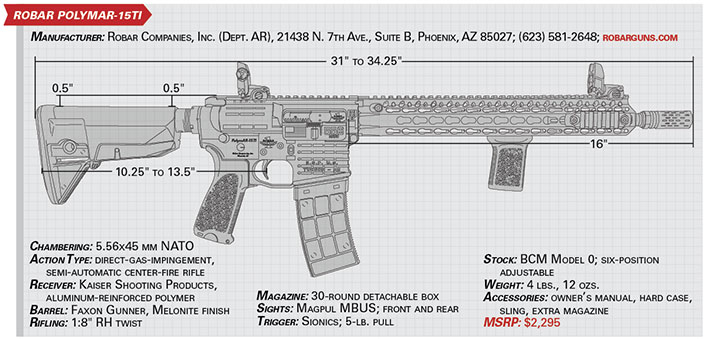

Robar Guns, a company usually associated with specialty firearm finishes and plating, recently introduced a lightweight variant of the AR-15. Weighing less than 5 lbs., the PolymAR-15Ti is a mixture of old technology and new materials assembled with a great degree of attention to detail. Featuring a 1-m.o.a. accuracy guarantee, the Robar gun also possesses the reliability needed for law enforcement, security, home defense and hunting.

The key to the PolymAR-15Ti’s light weight is its polymer upper and lower receivers. Manufactured by Kaiser Shooting Products, the receivers are molded with a proprietary blend of polymers specially compounded to provide strength. The upper and lower receivers together weigh merely 10 ozs.—compared to around 16 ozs. for conventional aluminum receivers. Kaiser reinforces its receivers, molding aluminum inserts into the polymer at critical areas such as the receiver ring, hammer and trigger pin locations, and the barrel nut area. The upper receiver does not possess a forward assist, but does have a polymer ejection port cover that is laser-engraved with an American flag and the legend “556 NATO”.

Another significant weight savings comes from Robar’s titanium bolt carrier, which, at 7.7 ozs., weighs about 30 percent less than a conventional bolt carrier group. The bolt itself is plated with Robar’s NP3 finish—a nickel-Teflon coating that is self-lubricating and extremely easy to clean. Robar uses a roller cam rather than the traditional rectangular cam, which reduces drag and friction, and provides smoother unlocking of the bolt.

In addition to the bolt carrier, the castle nut, takedown pins, receiver end plate, barrel nut, gas block, magazine catch and button, and the selector/safety are all machined from titanium. Titanium is roughly half the weight of steel yet three times stronger than aluminum and is extremely corrosion-resistant. The downside to this alloy is that it is more expensive than aluminum or steel and also more difficult to machine.

Robar uses a Faxon Gunner barrel on the PolymAR-15Ti. The barrel has a 5.56 mm chamber so it can safely fire both .223 Rem. and 5.56x45 mm NATO cartridges without pressure or extraction issues. Our test sample had a barrel length of 14.5" with a Bravo Company Mfg. 1.5" titanium compensator pinned and permanently welded to meet the 16" minimum barrel requirement. The barrel is rifled with 1:8" twist, has a mid-length gas system and is Melonite-treated for wear and corrosion resistance. The low-profile titanium gas block is covered by the BCM 13" free-floating, KeyMod handguard for a sleek, uncluttered profile.

Bravo also supplies the six-position collapsing stock used on the PolymAR-15Ti. The Gunfighter stock Model O is silent in operation, slides between positions easily and locks securely. The pistol grip is also a BCM part and has excellent ergonomics. It is of tapered design—thinner at the top and fatter at its bottom—and is textured for a secure grip. At its bottom is a hinged trapdoor, and Robar uses this storage area to include an extra firing pin and a Magpul MBUS sight tool.

Robar outfits the PolymAR-15Ti with a Sionics Enhanced Mil-Spec Trigger, which is also plated with an NP3 finish. Our test sample’s trigger broke cleanly at 5 lbs. To maximize the carbine’s accuracy potential, we mounted a Trijicon 5-20X 50 mm AccuPoint scope on it, which is certainly far more scope than needed for practical field applications with this gun.

Robar’s PolymAR-15Ti shot very well, with a number of the five-shot groups meeting the promised sub-m.o.a. accuracy guarantee, and the groups were nice and round without exhibiting vertical or horizontal stringing. We made no attempt to let the barrel cool between groups and found there was no shift in point of impact as the barrel warmed. Robar includes Magpul MBUS folding iron sights on the carbine, and the flat-top receiver design and rail-topped handguard lend themselves to any number of different optical options. Despite the gun’s extreme light weight, we found it to be very controllable during rapid-fire exercises.

We fired more than 200 rounds during our evaluation and had no stoppages of any type. One of the benefits of the gun’s polymer and titanium construction is that it can run just fine with minimal lubrication. In desert climes, where oil acts as a magnet to sand and dirt, this is extremely advantageous. Another benefit is that it is corrosion-resistant and perfect for salt water environments and areas with high humidity. But we think what most shooters will find most attractive is the gun’s light weight. In our opinion, nothing in the way of function or durability is sacrificed to achieve these weight savings, and the PolymAR-15Ti possesses the accuracy and reliability needed for just about any chore appropriate for an AR-15-type rifle.