For nearly five centuries, Beretta’s trade secrets and attention to detail have been passed from father to son, making the Italian industrial firm not only the world’s oldest gunmaker, but one of the oldest companies of any kind in the world. Historical documents show that in 1526, Mastro Bartolomeo Beretta of Gardone received 296 ducats in payment for 185 gun barrels sold to the Arsenal of Venice. Bartolomeo’s barrels were chosen for their superior design, materials and construction, and the transaction established the quality associated with his name.

Back in the early 1900s, Pietro Beretta (1870–1957) first introduced modernized manufacturing methods to the Beretta factory at Gardone. This not only simplified, but also streamlined production, and established Beretta as one of the most modern firearm production facilities in the world. The modernization process continued under the leadership of sons Giuseppe (1906-1993) and Carlo (1908–1984). Under their watch, the brothers steered the company into successful ventures that produced high-quality firearms for military, law enforcement and the private sector.

Today, under the leadership of Dr. Ugo Gussalli Beretta and his sons, Pietro and Franco, Beretta produces around 1,500 firearms a day, covering a wide range of uses: over-and-under, side-by-sides and semi-automatic shotguns in varying grades for hunting and sporting competition; bolt-actions and express double rifles; semi-automatic pistols in chamberings from .22 rimfire to .45 ACP; submachine guns; and even light machine guns. Seventy-five percent of Beretta’s production consists of sporting firearms, with 70 percent of the arms produced in Italy and exported to nearly 100 countries.

The Beretta factory is still located at the narrow end of the Brescia Valley, in the picturesque village of Gardone Val Trompia. It is the main industry in this northern Italian village, employing more than 800 people, all of whom are proud and passionate about their craft.

Stroll the narrow village streets near the Beretta Hotel, or visit the Beretta Firearms Museum at Beretta’s century-old headquarters, and you will be transported to another time and place as you sense the rich cultural heritage of a gunmaking dynasty. Housed in one of the buildings of the original factory is the gun room, which was, in fact, the 19th-century factory showroom. Pine floors and altar-like gun cabinets run for 30 yds. down each wall, lending the room a cathedral-like appearance. Midway down in one of the cabinets on the left-side wall hangs a copy of the Arsenal of Venice’s original order for the 185 arquebus barrels from Bartolomeo Beretta.

The museum’s display of gun history is, in essence, a journey back in time, while a glimpse at the future is only a short walk across the street to Beretta’s ultra-modern 225,000-sq.-ft. factory where its newest premium shotgun, the SL3, is being built.

Incorporating the latest manufacturing technology with the artistry for which Beretta is known has resulted in the SL3, an over-under that is both innovative and beautiful. This might beg the question: after 490 years of manufacturing firearms how does Beretta keep coming up with new and better ways of making high-quality shotguns? Beretta is obviously driven by the desire to constantly improve the design and performance of its shotguns.

For more than 40 years, the design and manufacturing methods for Beretta’s luxury gun program has been directed by Ferdinando Belleri, Beretta’s master craftsman who is affectionately and respectfully known as il Maestro by his Beretta co-workers and shotgun cognescinti who appreciate and understand his genius. Belleri personally oversaw the development and production of the SL3, building upon the Premium SO10 foundation, but producing a gun that is more sleek, accurate and moderately priced.

The popular SO—for sovrapposto, or superimposed—system was first developed in 1932, soon after Browning introduced its Superposed over-under shotgun. Beretta’s answer to the Superposed was the production of a lighter, sleeker over-under built on a very stout monobloc system, allowing barrels to be located lower in the receiver and in closer alignment with the shooter’s eyes and hands. As a result of the receiver’s low, straight profile, recoil is directed straight back, eliminating upward and side-to-side forces, and thereby minimizing stress on the gun’s locking mechanism. It also offers excellent target visibility and consistent shooting performance, whether the gun is pointed vertically or horizontally. The monobloc is still used today, not only in Beretta’s SO guns, but universally in all but the most expensive shotguns.

The SL3 is the culmination of close to three years of work to make something new, modern and stylish and, yet embodying all the classic elements of a Beretta SO shotgun. With a rounded receiver, newly designed ejectors, updated trigger guard and barrel tapering technology, Beretta has accomplished all of that. Cosmetically, three classic engraving options might adorn the SL3, but a fourth option offers a striking hand-polished mirror finish.

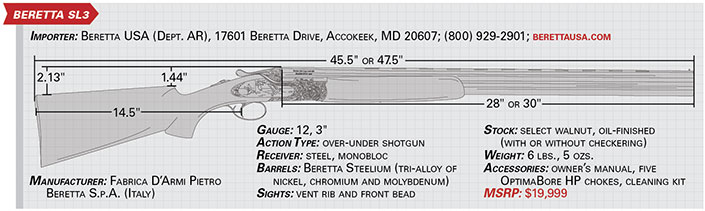

The gun is built on a reliable boxlock action engineered to withstand intensive use with heavy loads, whether in the field or at a target range. It is a proven Beretta design that ensures a reliable vault-like lockup. This is accomplished by anchoring the barrels at three separate points: the hinge pins, lower hooks and locking pins. It is similar to the SO10 that also uses a three-point locking system described by Beretta as “classic trapezoidal.” The SL3 also utilizes the SO10’s ejection system, which is based on precision ejectors guided on the demibloc. The contact area between the ejectors and the shell rim has been increased to guarantee a positive engagement of the cartridge. The system not only features greater reliability, but also makes the action easier to inspect and clean. The SL3 drew several proven features from other Premium Group guns, such as the leaf spring of the DT11. Its inertia trigger ensures a clean, crisp trigger pull. The Steelium barrels are also the same as the DT11, utilizing Beretta’s exclusive tri-alloy of nickel, chromium and molybdenum that uses a deep-drilling, cold-hammering process and vacuum distension to make shotgun barrels of very low material stress. The result is greater accuracy and durability for steel, lead and other alternative hunting loads.

The SL3 barrels, available in 28" or 30" lengths, include the OptimaBore HP choke system packaged with all of Beretta’s tournament-grade clays guns. Beretta tested the SL3 by firing more than 11,500 magnum loads through it without a single malfunction—the opening and closing of the barrels remained smooth and effortless throughout the test period.

Like the SO10, the SL3 is adorned with pinless sideplates that feature four different design motifs. A Renaissance-inspired ornamental motif achieves a bas-relief effect thanks to Beretta’s five-axis laser that can engrave rounded surfaces with perfect continuity of pattern. A game scene depicts pheasants on the left, ducks on the right and a partridge on the underside. The fine English scroll engraving aims at a traditional style, while a mirror-polished version requires hours of hand-polishing that borrows from the contemporary mirrored option of the SO10.

The SL3’s stocks are cut from high-grade, select walnut and sport a traditional hand-rubbed oil finish, highlighting the handsome grain of the wood. Hand-cut checkering completes the SL3’s stock work, although there is an option to forgo checkering in favor of a silky smooth look and feel, and which beautifully and dramatically complements the mirror-polished gun.

The SL3’s dedicated case is fashioned by Beretta’s Custom Gun Case Atelier, which has spared no expense in the hand-crafted construction. The case buckles reflect the SL3 receiver’s profile, while the locks are designed with the Pietro Beretta logo shield. The Beretta product design team chose a blue cotton canvas for the external fabric and an elegant, but contrasting, rich red lining. All the leather details are hand-crafted from the finest Italian leather and hand-stitched to the case itself.

I had the pleasure of handling and shooting the SL3 at a sporting clays course in Italy where the gun clearly demonstrated the practicality of its features and the soundness of its style. I was immediately struck by its balance and feel from the minute I held the SL3, and putting it to my shoulder confirms a desire to pull the trigger on a moving target at the soonest opportunity.

I walked to a shooting station and opened the action to drop two shells into the chambers. Bringing the buttstock to my cheek made me aware of the fine balance between the heft of the stock and the weight of the barrels. Sighting down the barrels was quick and certain, and maintaining a steady hold was easy.

When I called for a bird, the muzzle moved toward the target as I mounted the gun in a smooth manner that made dusting the clay feel like an expected and natural conclusion to the action. The muzzle acquired the target so smoothly and effortlessly it almost seemed to happen of its own accord. I was sold on the SL3 from the first shot, and completing a round of sporting clays merely confirmed my opinion that this shotgun will be perfectly at home, whether it’s in a cornfield dropping pheasants or at a range breaking clay targets. The SL3’s price tag at $19,999, is admittedly hefty, but it is literally an investment in the future of your shooting pleasure. The SL3 clearly exemplifies an intrinsic value that is certain to increase with time.

Inventiveness and respect for tradition, along with study, research, technical progress and modern production methods form the foundation on which Beretta’s reputation for quality stands. The company’s attention to such quality is a tradition that has carried over through 15 generations of one family, and, today, as exemplified by the SL3, is still the key to Beretta’s worldwide success.