Certain firearm designs and models are timeless and highly coveted, with a couple of obvious examples being the Heckler & Koch (H&K) Maschinenpistole 5 (MP5) and Benelli’s M4/M1014. Oftentimes these guns were—and in some cases, still are—employed by law-enforcement agencies and/or the military, and thus private ownership is limited due to one or more features that run afoul of gun-control legislation. Modified, civilian-legal variants are normally also introduced by the maker, however, these are usually costly and, at times, difficult to obtain. Fortunately, once patents expire, other manufacturers meet the demand with less costly clones. One such company is SDS Arms’ Military Armament Corp. (MAC).

Located in Knoxville, Tenn., SDS Arms is an importer that made its debut in 2017. Peruse the company’s website under its MAC brand and you’ll immediately notice a trend; only popular, time-tested models are offered. For instance, there are two semi-automatic-only handgun variants of the MP5 submachine gun, as well as the MAC 1911 JSOC 45, MAC 1911-9 Double Stack (February 2024, p. 54), and copies of the Benelli M4/M1014 and M2. I will focus on the latter two shotguns here.

Why did MAC replicate the Benelli M4/M1014 and M2? “The popularity of those two models has never gone away,” explained Neil Sanders, vice president of marketing for SDS Arms. “The wave of clones grew large, but MAC wanted to step back and make sure we did it right. We found the right manufacturer—Özerbas in Beysehir, located in the Konya region of Turkey—to work with us on creating a one-for-one clone to get it as close to the original iconic shotguns in not only fit but also in function. [Additionally], we are building brands based on quality and affordability with the features American consumers seek.”

MAC 1014

The origins of the MAC 1014 are found in the U.S. Army’s May 4, 1998, solicitation for submissions for a combat-ready, semi-automatic, 12-ga. shotgun. As a result, Benelli Armi SpA of Urbino, Italy, submitted its new M4 Super 90, which was the company’s first gas-operated shotgun. The innovative scattergun won the competition and was subsequently designated the M1014. The first batch was delivered to the Marine Corps in 1999. In the years since, the M1014’s use across the various branches of the military has increased markedly. So, too, has civilian interest. So, it’s understandable that MAC would reproduce the Benelli M4/M1014, which, depending on configuration, starts at $2,300 for an authentic gun.

The MAC 1014 is a faithful clone of Benelli’s M4/M1014, and most M4 aftermarket products are compatible with the much-less-expensive gun.

Outwardly, the 3"-chambered, 12-ga., semi-automatic MAC 1014 Pistol Grip and Marine Pistol Grip visually replicate the Benelli M4 Tactical, while the MAC 1014 Breacher more closely resembles the current Benelli M1014. And then there is the MAC 1014 Wood, a standalone. Consistent with the Benelli, the Pistol Grip and Marine Pistol Grip feature a fixed, black synthetic buttstock with bilateral sling mounting points. Capping the buttstock is a squishy recoil pad measuring upward of 7/8" thick. The pliable pistol grip, replete with grooves, enhances purchase. A protruding lip on the bottom of the grip prevents the hand from slipping.

If you’re clamoring for the multi-position buttstock of the military Benelli M4, forget about it. Due to import laws, it has been replaced on the Breacher variant with a fixed stock similar in appearance; the pistol grip differs, too. The MAC 1014 Wood features a furniture set crafted from Turkish walnut that does not include the pistol grip. It’s worth noting here that the MAC 1014 is compatible with most Benelli M4 aftermarket parts.

The 1014’s fore-end consists of two halves with a mid-length swell that cover its gas-operation system. These are secured by retaining bands; one is located on the front of the receiver, while the other projects downward from the barrel. Tension is provided by the snugged magazine lock nut.

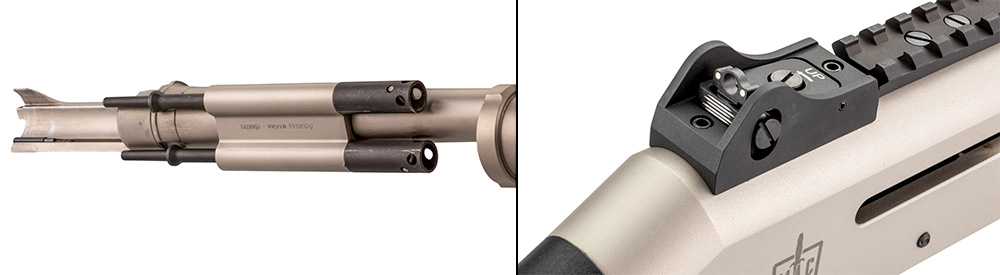

The MAC 1014’s action (l.) mimics Benelli’s fast and reliable A.R.G.O. system, a short-stroke, dual-piston design wherein the pistons themselves, rather than action bars or other linkages, interact directly against the bolt to cycle the gun. Sights on the MAC 1014 (r.) consist of a ghost-ring rear aperture and a front ramp; a section of Picatinny rail atop the receiver facilitates the use of an optic.

Other than the requisite serial number and model designation, the MAC 1014’s aluminum receiver has only the MAC logo on the right, rear side—a fitting, all-business appearance. Topping the receiver is a windage- and elevation-adjustable ghost-ring rear sight featuring a 0.195"-diameter aperture with white dots at the 3- and 9-o’clock positions. An aluminum, 5.25"-long Picatinny rail, secured with five M4 screws, is forward of the sight.

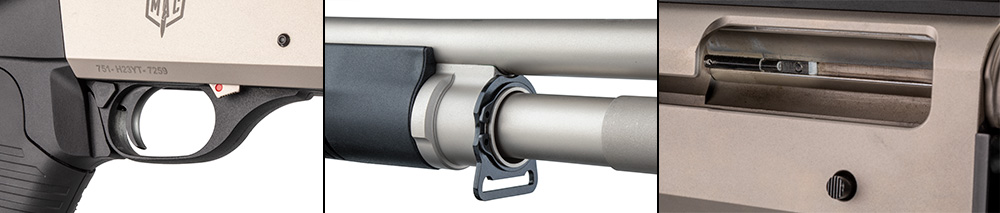

The bolt release, which is located on the front, right side of the receiver, is the only control not contained within the unitized, detachable fire-control group. These include: a carrier-drop lever; a triangular, crossbolt-style safety; and the single-stage trigger. Concerning the latter, on the sample provided, it broke at an average pull weight of 7 lbs., 15 ozs. There was noticeable creep, though it was smooth, and the reset was exceptionally short.

The heart of the MAC 1014 mimics that of the original. Coined “Auto-Regulating Gas-Operated” (A.R.G.O.) by Benelli, the unique system features a short-stroke, dual-piston design in which the pistons interact directly against the bolt, thereby speeding operation. The absence of action bars or linkages saves weight, too. Moreover, the dual ports fueling operation are located immediately forward of the chamber, rather than at some distance down the barrel. Why? Purportedly, this is due to the combination of gases being hotter and cleaner, thereby resulting in less fouling and enhanced reliability. Given the stellar reputation of the M4/M1014, that should be taken as gospel.

After the pistons interact with the bolt, the bolt head rotates out of lockup and begins its rearward movement, with the spring-loaded extractor removing the hull from the chamber. As the bolt carrier assembly moves to the rear of the receiver, it compresses the recoil spring contained within the buttstock. A spring-loaded ejector on the left receiver wall clears the hull at this time. As the rebounding recoil spring forces the bolt carrier assembly forward, the shell on the raised carrier is pushed into the chamber and lockup completed. A nice feature of the MAC 1014 is that the bolt carrier assembly can be retracted—via the charging handle—slightly for a chamber check and will return to battery, even if eased forward.

Controls integrated into the fire-control group (l.) include (front to rear) the carrier-drop lever, single-stage trigger and triangular crossbolt safety. A steel sling fitting (middle) on the MAC 1014’s magazine tube accepts a 1 1/4" sling and complements the slotted fitting integrated into the side of the buttstock. The bolt-release button is located on the right side of the receiver (r.) beneath the ejection port—through which the shotgun’s left-side ejector can be seen.

Feeding the MAC 1014 is a tubular, five-round magazine that is secured to the barrel in two locations. The follower is red anodized aluminum. Chambered in 3" 12 gauge, the MAC 1014’s chrome-lined, 4140 steel 18.5" barrel is threaded to accept omnipresent Beretta-Benelli Mobil choke tubes. Accompanying the shotgun are three unmarked, flush-fitting choke tubes. The constrictions are as follows: 0.682" (I); 0.705" (III); and 0.720" (IIIII)—all “tighter” than the number of notches would typically represent. The latter comes pre-installed. A post, winged front sight is mounted atop a raised platform. It is adjustable for windage and has a single white dot. Tools are provided to aid with front and rear sight adjustment, while a basic choke tube wrench accompanies the shotgun to facilitate choke changes.

The barrel, magazine tube and receiver of the MAC 1014 Marine Pistol Grip tested had an electroless, marine nickel finish, while the other variants have a black-anodized receiver with a black chromate coating on the barrel. The forward sling mounting point is rearward of the faux magazine extension.

MAC 2

MAC’s second shotgun series, the MAC 2, traces its lineage to another Benelli product, the semi-automatic M2, which debuted in the 1980s. Most firearm enthusiasts, and shotgunners in particular, are familiar with the popular M2; after all, the line has been sold in vast quantities for decades and remains a mainstay product for the Italian maker.

Fieldstripping the MAC 2 is straightforward and reveals the shotgun’s familiar construction. Note the QD stud on the magazine cap (inset, l.), which complements a molded fitting in the buttstock.

As with the original M2s, the 3"-chambered, 12-ga. MAC 2-series shotguns employ “inertia operation” developed by the Italian maker in 1967, which, since then, has earned a stellar reputation for reliability. The step-by-step actions of the inertia-operating system have been covered ad nauseam in these pages and thus won’t be detailed here. The design’s benefits, however, include: fewer parts; ease of cleaning and maintenance; longevity; and load diversity (without changing pistons, such as on some gas-operated shotguns).

The foundation of the inertia operating system is the simplistic bolt assembly, which consists of three primary parts: a rotating bolt head; an inertia spring; and the bolt body. Interestingly, removing the bolt assembly of the sample MAC 2 3-Gun model revealed its bolt body to be machined differently than the original, as it has multiple deep, long channels to cut weight while increasing speed. Operation is unchanged. The other MAC 2 variants—Tactical Marine, Tactical Marine Wood and Tactical Wood—don’t have this modification to the bolt. That being said, all have an oversized, cylindrical charging handle. This was one feature I disliked, as the handle rotated freely. A user with compromised hand strength could potentially lose purchase when retracting the bolt, causing it to slam forward prematurely. Beneath the handle is the bolt-release button that, although larger than the one on the MAC 1014, is smooth across the face.

The predominately black, and competition-minded, MAC M2 3-Gun comes with a red fiber-optic front sight (l.) and an orange plastic magazine follower (r.).

As with the MAC 1014, the fire controls of the MAC 2 are contained within a single unit and are identical. On the sample, the single-stage trigger broke at an average of 5 lbs., 15 ozs. The trigger exhibited significant creep, but it was smooth, and the reset was quite short.

The matte black-anodized 7075 aluminum receiver of the MAC 2 3-Gun is relatively unadorned; in fact, like its MAC 1014 counterpart, it only has the serial number, importer name and location, country of origin and MAC logo. Outside of a cutout and a series of long grooves to reduce glare, the top of the 3-Gun’s receiver is bare. Those on the other MAC 2 variants mimic the configurations of the MAC 1014, featuring a ghost-ring rear sight and Picatinny rail. There is a significant change to the 3-Gun’s receiver that’s only obvious to the discerning eye. Look beneath it and you’ll see an enlarged loading port that’s designed to hasten loading during competition and when wearing gloves. There is also a notch forward of the trigger guard to further guide shells into the loading port.

The MAC 2’s bolt assembly features the rotating head (l.) with attached extractor, a heavy spring between it and the lightened body and a tail that contacts the recoil spring located in the buttstock. Controls on the right side (r.) of the MAC 2’s receiver (front to rear) are: a bolt-release button, an oversize charging handle, a carrier-drop lever and a crossbolt safety button.

Affixed to the front of the MAC 2 3-Gun’s receiver is a 21" or 24" black-chromate-finished, chrome-lined, 4140 steel barrel featuring a ventilated rib ending with a red fiber-optic strand. The other MAC 2 variants have 18.5" barrels with the same winged, ramp front sight as the MAC 1014. All are threaded to accept Beretta-Benelli Mobil choke tubes. Again, matching the MAC 1014, three, flush-fitting chokes in the same constrictions are provided, and the IIIII (0.720") choke comes installed. However, on the MAC 2 3-Gun, the follower in the tubular magazine was made from orange plastic, not metal. As an aside, MAC’s sister company, Spandau Arms, will offer 24"- and 28"-barreled versions of the MAC 2 3-Gun coined the “S2.”

Where the MAC 2 models deviate most is in regard to the buttstock and fore-end. The 3-Gun model has synthetic furniture with integral checkering on the pistol grip and fore-end, and the buttstock is capped with a contoured, 0.810"-thick recoil pad. A molded-in sling attachment point is found on the buttstock, and the corresponding sling swivel stud is located on the aluminum magazine tube cap. The Tactical Marine’s furniture differs in that the forward sling attachment point is on the tubular magazine itself, just like the MAC 1014. The Tactical Wood and Tactical Marine Wood models match this configuration with the exception that the stocks are made from Turkish walnut, and, naturally, the rear sling swivel stud is screwed directly into the wood. Aftermarket parts, accessories and furniture that’ll fit on the Benelli M2 will work seamlessly on the MAC 2-series guns. Metal finishes on the MAC 2s match those on the MAC 1014s.

Testing

It’s always prudent to read the owner’s manual before heading to the range. Why? For starters, page one of the MAC 1014’s manual suggests firing: “One hundred rounds of 1,350+ f.p.s. ammo for a break-in period. Your shotgun will cycle lighter loads after completing the proper break-in period.” What’s more, it was suggested that, at a minimum, 1 1⁄8-oz. loads are used, and 1,350 f.p.s. was the lowest suggested velocity. So the search for a suitable load began.

What I discovered was, other than the odd buckshot and slug loads, as well as shells fit for waterfowling, few shells meet the aforementioned criteria for payload and velocity. And those that do are costly. Take heed. So, I opted for handloading. According to Hodgdon Powder Company’s website, I could attain 1,365 f.p.s. using the following recipe: Remington Gun Club 12-ga., 2¾" hull; Winchester 209 primer; 28.5 grains of Winchester WSF propellant; a Winchester WAA12 (or clone) wad; and 1 1⁄8 ozs. of lead-alloy shot. Since I was breaking in the MAC 1014 Marine Pistol Grip on a combined handgun/shotgun range, I opted to use up some excess magnum No. 5 shot. I loaded 100 shells. Being an inertia-operated gun, the MAC 2 3-Gun shotgun doesn’t have a break-in process. After a quick cleaning/lubrication of the guns (including removing the chokes, which had no anti-seize or grease), I headed out to the range.

What I discovered was, other than the odd buckshot and slug loads, as well as shells fit for waterfowling, few shells meet the aforementioned criteria for payload and velocity. And those that do are costly. Take heed. So, I opted for handloading. According to Hodgdon Powder Company’s website, I could attain 1,365 f.p.s. using the following recipe: Remington Gun Club 12-ga., 2¾" hull; Winchester 209 primer; 28.5 grains of Winchester WSF propellant; a Winchester WAA12 (or clone) wad; and 1 1⁄8 ozs. of lead-alloy shot. Since I was breaking in the MAC 1014 Marine Pistol Grip on a combined handgun/shotgun range, I opted to use up some excess magnum No. 5 shot. I loaded 100 shells. Being an inertia-operated gun, the MAC 2 3-Gun shotgun doesn’t have a break-in process. After a quick cleaning/lubrication of the guns (including removing the chokes, which had no anti-seize or grease), I headed out to the range.

Obviously, one should adhere to the suggested break-in process, but I’m also not naïve and thus realize some consumers won’t do so (at least initially), so I wanted to first evaluate functioning of the MAC 1014 with lighter loads before starting the “official” break-in procedures. The assortment of 12-ga., 2¾" shells, which featured 7/8 oz. (1,350 f.p.s.) to 1 oz. (1,200 to 1,290 f.p.s.) of lead-alloy shot, all functioned flawlessly. This is not to suggest that one should disregard the maker’s recommendations, as gremlins tend to appear at the most inopportune times, but it was a good sign.

Through the 100-round, load-and-dump fest, the sample MAC 1014 exhibited no malfunctions, and that continued afterward, when it was fed a steady diet of randomness, ranging from 3", 2-oz. turkey loads to 2¾" shells with slugs or brimming with birdshot and buckshot at a variety of velocities. There were no issues whatsoever—again, a testament to the Benelli M4/M1014 design and MAC’s fidelity in duplicating it. The recoil generated by the magnum loads was offset somewhat by the gun’s near-8-lb. weight, gas operation and the pistol grip, which aided control.

Finally, with the III-notch choke tube inserted, I commenced pattern testing at 25 yards. The load I selected was Remington’s Ultimate Defense 2¾" 00 Buck, which featured nine pellets. The pattern results can be found on p. 39. Despite patterning several inches high—remember, the sights can be adjusted—pellet distribution was fairly uniform.

I evaluated the MAC 2 3-Gun with a variety of shells as well, fluctuating from Fiocchi’s Shooting Dynamics 12-ga., 2¾" shell propelling 7/8 oz. of No. 7 1/2s to 1,350 f.p.s. to Migra’s 3" 1/3 Stack Load Steel Shot, which attains 1,515 f.p.s. with 1¼ ozs. of shot. Most target-type shells used were those that’d pull double-duty for upland hunting, but I tried a host of slugs and buckshot, too. The result? No issues whatsoever. The sample 3-Gun fed, fired, extracted and ejected without problems throughout the function-testing phase. Weighing 6 lbs., 8 ozs., recoil generated by hard-hitting loads—particularly those designed for waterfowling and speedy slugs—was jarring, yet not intolerable, thanks to the recoil pad and a firm hold.

I evaluated the MAC 2 3-Gun with a variety of shells as well, fluctuating from Fiocchi’s Shooting Dynamics 12-ga., 2¾" shell propelling 7/8 oz. of No. 7 1/2s to 1,350 f.p.s. to Migra’s 3" 1/3 Stack Load Steel Shot, which attains 1,515 f.p.s. with 1¼ ozs. of shot. Most target-type shells used were those that’d pull double-duty for upland hunting, but I tried a host of slugs and buckshot, too. The result? No issues whatsoever. The sample 3-Gun fed, fired, extracted and ejected without problems throughout the function-testing phase. Weighing 6 lbs., 8 ozs., recoil generated by hard-hitting loads—particularly those designed for waterfowling and speedy slugs—was jarring, yet not intolerable, thanks to the recoil pad and a firm hold.

As for patterning, I opted to use Gamebore’s Rose Gold Pro Comp 2¾" loads featuring 1 oz. of No. 7½ shot at 1,200 f.p.s.—a premium, dual-use competition and upland shell—paired with the III-notch choke tube. The full pattern results are found nearby. It’s worth mentioning here that, although the aforementioned shell is considered “one ounce,” the actual payload weighed around 426 to 427 grains, and thus contained about eight or so pellets less than a comparable 1-oz. shell. Since Gamebore produces 28-gram (432-grain) loads for markets outside the U.S., this isn’t surprising.

With patterning and function testing completed, I then transitioned to conducting loading and shooting drills from multiple positions on cardboard targets at distances ranging from 7 to 25 yards. Thanks to its lighter weight, the MAC 2 3-Gun was easy and fast to maneuver when “running and gunning,” as was loading; in fact, the tubular magazine could quickly be filled to capacity without looking. I cannot speak highly enough of the improved loading port. But, as much as I enjoyed engaging targets with the Mac 2 3-Gun, I preferred the heavier, gas-operated MAC 1014. I found it more controllable and comfortable to shoot, and when engaging multiple targets while moving—forward, backward and sideways—at a steady pace or working around barriers, the gun was rock solid and seamlessly moved between the paper-made “threats.” I now understand the reasons for the M4/M1014’s popularity. Was its trigger heavy? Sure, but it didn’t affect the results on the range.