The aluminum-frame R51 in 9 mm Luger was introduced in 2014, but issues with internal tolerances and the magazines led Remington to a full recall. With the issues fixed, the R51—shown here with an Alien Gear Cloak Tuck 3.0 holster—is back and being made in Huntsville, Ala.

It was not an auspicious beginning. Remington put a lot of time and effort into a new pistol product, and the blasted thing just wouldn’t perform. At a 2014 new product seminar for the firearm press—held at Arizona’s Gunsite—we found that out. My friend, well-known firearm authority Gary Paul Johnston, and I were side-by-side on the firing line. There were many samples of the gun on hand for shooting, and Gary and I must have fired a dozen or more of them. Most of the many malfunctions were associated with proper feeding. It was a disaster for Remington, our nation’s oldest firearm maker, which compounded its problem by releasing some unknown number of the flawed guns to the public. Shooters bought them, had trouble and returned them for repair. Eventually, there was a recall, and the old-time gunmaker’s effort to reprise the Model 51 compact semi-automatic just plain failed.

To Remington’s credit, the firm handled the problem with a sense of fair play. There were several options for dissatisfied buyers—money back, factory repair or a replacement gun. Some unknown number of production guns worked well enough, but many buyers went for the replacement gun. They had to wait for more than a year. It took a while for the company engineers to completely identify the problems and make appropriate modifications to correct them. When they were satisfied, revised Model R51s went back into production. And those patient customers who chose to wait were the first to get the upgraded pistols when they were re-introduced in 2016. That is the fair way to do it.

So the R51 is now a practical reality, at hand for review in these pages. What was Remington trying to accomplish in the first place? It was the company’s intention to offer concealed carry users a competitively priced hideout gun strongly based on a classic pistol from the firm’s storied past. That gun was the widely respected Model 51, designed by firearm genius John Pedersen of World War I Pedersen device fame. Some 60,000-plus specimens of the original Model 51 were made and sold in the period between 1918 and 1927. The slim and graceful 51s were made in .32 ACP and .380 ACP, and gave dimensionally similar guns from Colt, Smith & Wesson and Savage some stiff competition. I once owned and used a Model 51 in .380 ACP, and found it to be a unique and reliable semi-automatic pistol, beautifully fitted and finished. The original was distinguished by a unique operating system and ergonomics that Pedersen labored to perfect.

As a practical matter, it would be impossible to replicate the original Model 51 in today’s gunmaking economy. It would also probably be unwise to launch a medium-size pistol in .380 ACP, a chambering used in the originals and still deemed adequate for personal defense, if only just. That’s because there are many smaller, less expensive and more easily carried pistols available in this chambering. The original Model 51s used a very complicated system of delayed-blowback operation, which worked well with their .32 ACP and .380 ACP chamberings. Today’s cartridge of choice, however, is 9 mm Luger, and the modern R51 is designed around it.

The R51 pistol, made in Remington’s Huntsville, Ala., factory, measures 6.68" by 4.63" by 1.08" (length, height, thickness). Weighing 22 ozs., the R51 has a rather heavy steel slide atop a slim aluminum frame. Note that the slide’s thickness is slightly less than an inch. Immediately noticeable are the R51’s excellent ergonomics. With a shape that is conducive to close-range speed shooting from concealment, the gun is a close copy of the original Model 51 of the 1920s. Its contours were developed by John Pedersen, who created several models and had them evaluated by multiple shooters. The result was a handling gem, sold originally as “fits your palm like the hand of a friend.” The butt section of the R51 meets the upper at a slightly steeper angle than most of its contemporaries. This alone causes it to point a bit better. The trigger pivots from the top edge of the trigger guard, so there is room for a high, rounded relief contour at the lower rear corner. This shape sets the hand higher on the gun, thereby improving recovery from recoil. The backstrap incorporates a grip safety with a high pocket for the web of the shooter’s hand, another excellent contour. Although the pistol is a slim, single-column gun, the width of the butt section is wide enough to disperse recoil across the shooter’s palm.

The R51’s controls are minimal. There is no active safety or decocking lever. A passive grip safety, pivoting at the base of the backstrap, works on the strength of an internal spring, which demands a strong, high grip. On the left side of the receiver, there is a typical slide lock, which also works as the takedown catch in the manner of the M1911 pistol. Magazine release buttons are on both sides of the frame and drop the magazine free with an inward push. The buttons are large ovals with checkered surfaces, and are recessed down into the receiver. So are the checkered stock panels, which are polymer, replaceable and held in place with screws. On the front of the frame, there’s a crisply executed panel of checkering. Although they are barely perceptible, there are approach recesses on the frame, just to the rear of the trigger guard.

Remington’s designers got real futuristic with the R51 pistol’s slide. It has the swooping curves of an Italian sports car, but beauty is in the eye of the beholder so, if the curves offend you, just look at the conventional square post front sight and squeeze. The sights, front and rear, are dovetailed into the slide top and, yes, there are the typical three-white-dot type. The rear sight is much different from the norm. Clearly shaped to match the slide’s rear curve, the sight has a sharp front edge for racking the slide on one’s boot or belt, if necessary. It is a subjective opinion, but I think the gun has a fresh new look that is cool. And all those curves and tapers facilitate handling from concealment. The gun should be a winner for the concealed carry folks.

Remington’s R51 is a single-stack (seven-round capacity), single-action-only, nearly all-metal 9 mm Luger pistol. It is not a recoil-operated gun because there is no locking system that holds the barrel and slide together until the bullet exits the muzzle. For years, we have understood that the 9 mm Luger is too intense for anything but a recoil-operated mechanism. There have been many efforts to use a delayed-blowback system for the 9 mm Luger, but they have not met with success. The R51 is a hybrid delayed-blowback 9 mm, and I do not believe the gun’s strength or ability to take the pressures and velocities are in question.

While we have made many references to the original delayed-blowback Pedersen Model 51 pistol, the R51 has a different kind of delayed blowback. It has sometimes been referred to as a “hesitation lock”, and that is probably as descriptive as any (see Mark Keefe’s explanation starting on p. 61). Stationary throughout the operating cycle, the barrel is surrounded by a strong recoil spring and bushing, as well as a separate breechblock. As rearward force is applied in the act of firing, the breechblock tilts briefly, and this keeps the slide in place until the bullet exits the muzzle. This part of the cycle seems to work quite well.

As important as these technical points are, I was most interested in seeing how the new R51 shot, so I headed to the range with the gun and a bunch of ammunition. I planned to do a great deal of function shooting, so I took a couple of 200-round cartons of Cameron Hopkins’ new Super Vel Training ammunition. There were problems with the first two magazines. The pistol would not efficiently strip the top round out of the magazine and feed it into the chamber. After a fair amount of effort expended, including several trips to the range, I gave up and reported the problem to Remington.

In short order, I received new magazines. With a variety of ammunition, I headed back to the range and enjoyed a morning of completely trouble-free shooting. The gun functioned perfectly with the new magazines. It is evident that all the effort John Pedersen put into shaping the original Model 51 .380 ACP 100 years ago is still relevant today. In shooting the 21st century 9 mm Luger version, you can’t help but notice that even +P recoil in the 22-oz. gun doesn’t bounce you off the target. The axis of the bore is very close to the top of the hand, so recoil is not so much reduced, but rather vectored straight into the palm.

Other than the initial magazine difficulty, the R51 was a good shooter. Accuracy was quite good at personal-defense distances, and the gun is very easy to manage. It is a pure single-action trigger, where pressure on the trigger releases the internal hammer to fire the round. There is a very small bit of slack, followed by a clean break with a rather firm 5 lbs., 8 ozs., of pressure. Surprisingly, there is no discernible reset. This will perplex those shooters who rattle out fast pairs by allowing the trigger to move back only as far as the reset.

In many ways, Remington’s R51 is a unique handgun—in appearance, mechanical operation and ergonomic design. Today’s defensive shooter, especially, will appreciate its size, chambering and handling qualities, not to mention its modest price tag. Though its initial introduction was less than ideal, the R51s currently coming off the production line exhibit plenty of positives, and merit a second chance.

Figuring Out The Pedersen Hesitation Lock

The operation of the original Remington Model 51 has been called many things—delayed blowback, retarded blowback and even just a blowback. None of those are really true. The action’s movement is technically retarded and delayed—but by the locking of the breechblock to the frame after it starts out unlocked. Too, the slide’s recoil moves the locked breechblock out of engagement. Confused yet? The Model 51 and the new R51, are actually a form of hybrid blowback/recoil operation. Previously in these pages we have called it an “impinging action,” and others have dubbed it a “momentum action.” In a 1978 Gun Digest article, Donald M. Simmons, Jr., gave perhaps the best description of the Model 51’s history and operation, and he preferred “blowback/recoil operation.”

The term I’ll use here, though, is Pedersen hesitation lock. It’s not a locked breech, but it has a breechblock that locks. The product of design genius John D. Pedersen, of Pedersen device fame, it has only been used on two production handguns (I’ll leave the Model 53 out of this), and those are the Model 51 and the now re-introduced R51. The R51 follows the Model 51 kind of like a new Ford Mustang (as opposed the Mustang II) pays homage to the original—keeping the premise and principles, but with updated, modern styling, different internal design and changes in manufacturing technology.

So why is the Pedersen hesitation lock a big deal? Because, typically, slide mass and recoil spring tension are the only factors that keep a blowback gun closed long enough for the bullet to exit after firing as pressures drop to a safe level before the slide opens. That’s why blowback pistols typically are chambered for less powerful cartridges than 9 mm Luger and/or have heavy, bulky slides along with beefy springs. Ever seen a Hi-Point C-9?

The steel slides on the Model 51 and R51 are slim and of lighter weight than most other contemporary blowback pistols of either era. For the Model 51, the result was a great-pointing, lightweight .32 or .380 ACP. For the R51, it means a more powerful 9 mm Luger chambering in a size not much larger than most .380s. And that’s due to a separate breechblock inside the slide that adds a momentary locking phase to slide operation. That mechanical lock allows the slide to hesitate in its rearward movement just long enough for the pressures to drop.

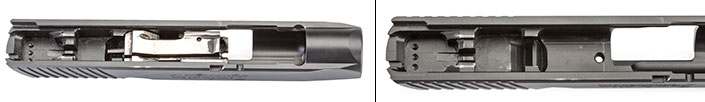

The breechblock containing the bolt face and firing pin is typically machined integrally in a pistol’s slide. On the Model 51, it is a separate assembly consisting of the breechblock itself, the firing pin and firing pin spring, plus the extractor. On the R51, the steel breechblock has all the components neatly pinned into one assembly. Operation is on similar principles, though the location, size and angles of the lugs and cam surfaces are vastly different between the 51 and the R51. On the 51, those surfaces are on the inside of the breechblock; on the R51, they are external.

As a cartridge is fired, the barrel stays right where it is, being fixed by what is usually called a slide stop pin, even though Pedersen himself called it the barrel lock pin in the 51. The steel slide and breechblock recoil together just as with any other blowback-operated pistol for a very short distance. Simmons wrote the original was a 0.83" and, using calipers to average 10 movements, I came up with a 0.81" on the R51.

It’s at this point that both Pedersen hesitation lock pistols stop acting like blowbacks. Note that the case head is momentarily unsupported, as the straight-walled case is still containing the expanding gases. Not to worry; it’s only for a few milliseconds, and that is the toughest, thickest part of the case (from a case support standpoint, this happens with tilt-barrel designs, too). Simmons wrote that the Model 51 would not function without its extractor; I did not try that with the R51. Note that straight blowback pistols don’t really need an extractor, and some don’t even have one. The new R51’s extractor is pretty beefy, 0.089" long and 0.018" tall, and instead of a coil spring, it employs an elastomer extractor button.

Due to that short amount of movement, the gun changes operation; it doesn’t stop operating, it just changes how it operates. On the R51, as the slide and breechblock are forced rearward by the pressure of the cartridge case pushing against them, they move until a 0.641" wide, 0.105" tall underlug on the bottom rear of the breechblock comes into contact with locking shoulders on the aluminum frame. This locks the action—push on the breechface itself all you want, it won’t budge—but not for long.

Because of cam surfaces cut on either side of the inside of the slide and the sides of the breechblock, the slide, which wants to keep moving after being started on its way by the movement of the breechblock, then travels 0.189" (on the 51 it was 0.20"). The cam surfaces push the front of the breechblock down, tilting its rear upward. This clears the underside locking lugs from the frame and the top lug from the inside top of the slide.

At this point, the breechblock and slide recoil together, and the cartridge case, held by the extractor on the bolt face, travels with them until kicked out of the action port by a frame-mounted, blade-style ejector on the gun’s left. The recoil spring, which surrounds the barrel like a Walther PP, then pushes the slide forward, stripping a fresh cartridge out of the magazine and taking the breechblock and slide back into the forward-most position. There’s a 0.356" wide and 0.031" tall lug on the top of the bolt that, with the forward movement of the slide, moves the front of the breechbolt back into its raised but unlocked position. The R51 is then ready to start the whole process over again, with a pull of the single-action trigger dropping the internal hammer and setting off the primer.

So why have a gun that is unlocked when you pull the trigger, then locks, then unlocks again? It is to eliminate the tilting barrel common on Colt/Browning pistols (and Pedersen may have been trying to get around Browning’s patents with an impressive pile of his own), putting the bore axis lower in the hand, and getting a relatively svelte slide. The Pedersen hesitation lock eases the effort required to pull the slide back in terms of weight or spring tension, frankly making it one of the easiest action types to manipulate on the market, today. Like many owners of the original Model 51, new R51 users may not even be aware of just how much of John D. Pedersen’s genius went into the gun’s design.

—Mark A. Keefe, IV, Editor In Chief