On June 6, the Sporting Arms and Ammunition Institute (SAAMI) published eight new standards that barely gained the attention of enthusiasts or writers, including myself. The fact that the new “Suppressor Thread and Socket” drawings will minimize gun owner frustration, improve safety, heighten performance and save you money—even if you aren’t one of the 1.5 million or so suppressor owners—deserved more headlines than the August press release garnered.

Last week, I grilled an engineer who was a member of the SAAMI working committee that developed the drawings. He modestly asked me to withhold his name, explaining the accolades should go to the group that produced them, not himself. The work took two years to complete, with a minimum of one meeting a month. The team was composed of multiple designers from some of the industry’s biggest companies.

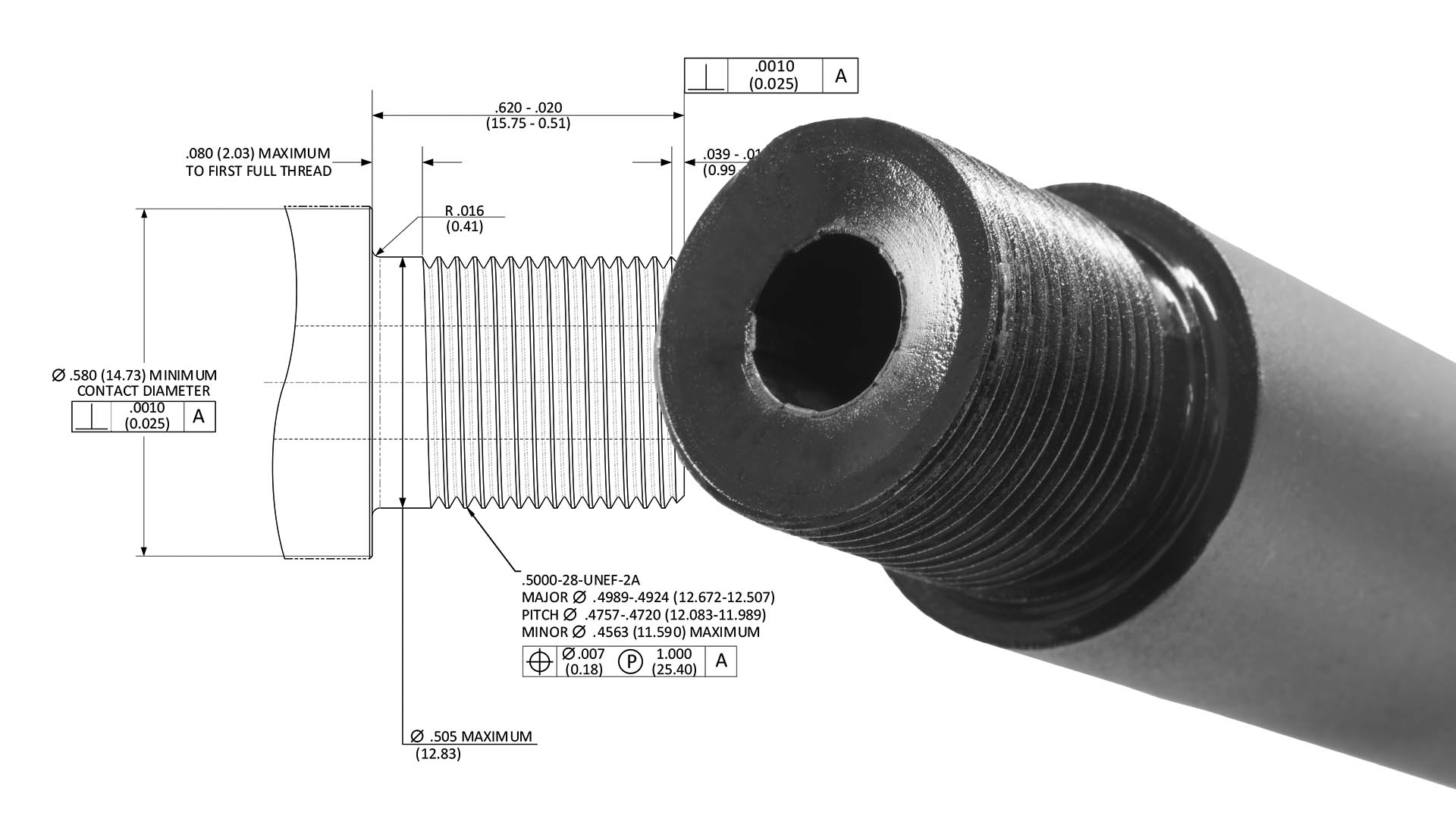

Most of today’s rifles and many handguns ship from the factory with threaded barrels. They wisely wear a protector, brake or flash hider to prevent damage to those finely machined grooves. The industry has largely agreed on a caliber-specific number of threads per inch (TPI) for years. To the average enthusiast, that might seem standardized, but it’s not quite that simple.

There are a variety of other factors that can make installation of a seemingly TPI-compatible device frustrating. The thread count might match that of the barrel, but the angles on those tiny peaks and valleys don’t always quite match. When that’s the case it can reflect as a reluctance during mounting, result in microscopic marring, require more torque than recommended or in rare cases, fail to mount properly. All can affect accuracy and repeatability.

The new mechanical drawings prescribe a long list of precise measurements that ensure SAAMI-spec muzzle devices will mount properly to SAAMI-spec threaded barrels. They include those angles and much more.

The increase in suppressor ownership was a large catalyst for the new standards. Bearing surface, shoulder and other standardized dimensions now minimize the risk of baffle strikes, unpredictable shifts in point of impact and indexing frustration. Other muzzle devices also reap the dimensional commonality benefits.

Interestingly, the engineer said nearly every company represented in the working group had minutely different dimensions in their threaded barrels and muzzle devices. They didn’t make a huge difference, but each firm agreed to compromise for the benefit of gun owners.

He recommends enthusiasts get in the habit of checking or asking if the gun or accessory they are considering meets the specifications, at least while the standardization transition is underway. His company—nameless here to honor his anonymity request—and many other firms implemented the dimensions almost immediately.