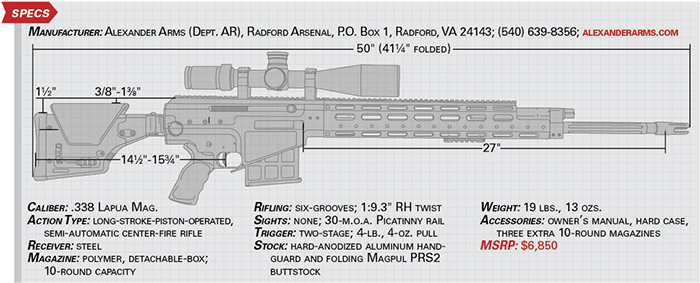

Since its founding in 2001, Alexander Arms has, time and again, challenged the status quo of firearm and cartridge design. Its first creation, the .50 Beowulf, was a specialized, rebated-rim, .50-cal. cartridge with short-range stopping power unequalled by other AR-15-compatible cartridges. The 6.5 mm Grendel, an intermediate-range cartridge, followed, as did one of the few successful .17 HMR-chambered semi-automatic rifles, and the only one that’s built on an AR-15 platform. The semi-automatic Ulfberht .338 Lapua Magnum, reviewed here, is the company’s largest offering—and perhaps the most innovative to date.

Outside of its name, which is owed to a distinctive, exceptionally strong Scandinavian Viking sword produced between 1,000 and 1,200 years ago, the Ulfberht is unlike its predecessors; given its size and operating pressure, obviously the .338 Lapua Mag. cartridge cannot be employed in Alexander Arms’ preferred platform, the AR-15. For this reason, Bill Alexander sought design inspiration from a new platform, and he found it in Russian firearm designer Vasily Degtyaryov’s Pulemyot Degtyaryova Pekhotny 1928 (DP-28) light machine gun.

The simple, yet effective, DP-28 used gas operation with a non-rotating bolt, short bolt-carrier group, long-stroke piston and unique bolt lockup. Concerning the latter, two cutouts in the bolt body enabled dual locking flaps (lugs) to pivot into and out of recesses milled into the receiver walls. But, the DP-28 wasn’t without its faults, either; for example, the recoil spring, which was beneath the barrel and surrounded the gas piston, purportedly lost its temper due to overheating from full-automatic firing.

For the Ulfberht, Alexander retained much of Degtyaryov’s design, with some refinements. These included inverting the gas operating system to permit bottom-feed loading from a detachable magazine, adding a five-position gas regulator to enhance reliability (with low- and high-pressure ammunition and suppressors) and adding a recoil-reduction system that, because of a long bolt run-out (nearly twice the cartridge length) and the absence of a sudden stop, significantly dampens the rifle’s kick. A buffer was also added to prevent damage in case an incorrect gas regulator setting is used.

How does the system work? During firing, gas bled from the barrel impinges on the piston, which is connected to the carrier. This unit is attached to the bolt, which contains the firing pin, heavy-duty plate extractor and dual plunger-type ejectors. As the bolt carrier group moves back, the locking flaps (lugs) disengage the recesses in the receiver wall. This permits the carrier group to travel rearward, extracting and ejecting the case and cocking the AR-style hammer. After compressing the 12"-long, nested recoil springs, the unit moves forward, stripping a round from the magazine and re-locking into battery. A polymer feed ramp prevents damage to bullet tips. Interestingly, there are only 10 moving parts on the Ulfberht.

The Ulfberht’s knurled, steel, reciprocating charging handle rides in a channel above the ejection port. There is no bolt hold-open feature. As a safety measure, the firing pin is interrupted by the locking lugs (flaps) and is unable to fire unless the bolt is in battery.

Contributing greatly to the rifle’s 19-lb., 13-oz. weight is its machined steel receiver. Steel was used because the bolt’s locking lugs actually mate with recesses in the receiver walls. The solid construction also stands up to operating pressures and helps support the hefty barrel. The ejection port is on the receiver’s right side. The operation and location of the left-side, two-position safety mimics that of the AR; however, the magazine release consists of a winged tab at the front of the trigger guard. A conscious effort is required to press the tab forward to release the magazine. An oversize trigger guard provides easy access to the two-stage trigger, which, on the test rifle, broke at 4 lbs., 4 ozs., with minimal creep and no overtravel. Although an Ergo Grip is provided, the Ulfberht accepts any AR-style pistol grip.

Secured to the receiver via a single detent pin is a right-side-folding Magpul buttstock that’s adjustable for length of pull and comb height. The latter helps optic-to-eye alignment. Removing the pin enables the buttstock (and attached, nested recoil springs) to be removed for maintenance. Capping the buttstock is a 3/4"-thick hard rubber recoil pad.

Attached to the top of the steel receiver is a hard-anodized aluminum cover that, in addition to having a channel for the reciprocating charging handle, is home to an 11½" strip of Picatinny rail. When combined with that atop the anodized aluminum handguard, there’s a continuous 36" of rail with 30 m.o.a. built in. Moreover, additional strips of rail can be added to the handguard along its length at the 3-, 6- and 9-o’clock positions.

Press-fit and pinned into the receiver, the Ulfberht’s 27", 0.885"-diameter barrel has M18x1.5 metric threads at the muzzle for a brake or silencer. The test rifle was fitted with a flash hider; given the gun’s minute recoil, there was no need to replace it with a muzzle brake. Deep flutes in the barrel serve to increase its surface area, and, along with oval slots in the handguard, hasten cooling. The barrel features 1:9.3"-twist, Enfield-pattern rifling to stabilize the heaviest .33-cal. projectiles and those featuring heavy jackets. Feeding the Ulfberht is a detachable, polymer, double-stack box magazine that holds 10 cartridges.

What better way to test an all-conditions rifle than to head to the range during a driving rain. With the rifle inundated and the tester soaked, the accuracy-testing portion of the evaluation was conducted. Three distinct loads were used—Black Hills 225-gr. BTHP MatchKing, Cor-Bon 225-gr. T-DPX, and Hornady 285-gr. BTHP—and five consecutive, five-shot groups at 100 yds. were fired with each. The gun was topped with a Steiner Military 5-25X 56 mm riflescope. The results are tabulated nearby, but suffice it to say that the Ulfberht is capable of producing fine accuracy. Even with the unfavorable weather, there were no failures to feed, fire, extract or eject. And, with only a simple wipe down, there was no rust after the rainy shooting session. All materials used in the construction of the Ulfberht are either corrosion-resistant or coated to provide the same. And, with only 48 individual parts, maintenance is simple.

We were pleasantly surprised at the minimal recoil produced by the Ulfberht; it could be described as being between a .223 Rem. and a .243 Win. There was also very little muzzle rise or gun movement.

We could only find two suggestions for improvement. First, while there’s virtually no chance of unintentionally dropping the magazine, the magazine-release tab required too much pressure to activate—especially from the bench. Second, the buttstock is secured to the receiver via a single detent pin that permits the buttstock to move up and down approximately 1/8". This is problematic in that it affects comb height and, if unsupported, can cause vertical stringing.

After thoroughly testing the Ulfberht, we feel that it lives up to its Norse moniker and we can’t wait to see what Bill Alexander comes up with next.