You have a rifle and you’ve come to find that it isn’t consistently accurate—occasional fliers, larger than expected groups or you find that you have to rework the scope’s dials constantly. Such problems can be exacerbated with larger and heavy-recoiling chamberings. Many times, we can narrow the source of frustration down to the scope and how it was mounted to the action.

Proper scope mounting doesn’t mean that you simply screw down the bases, attach the rings and head to the range. Even in today’s world of computer-controlled machining and high-tech castings, flaws occur, and diligence is required to detect them during installation.

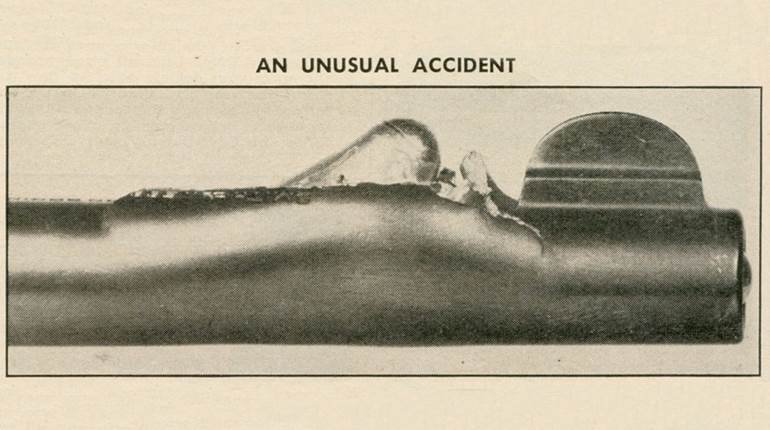

Recently, someone brought me a gun and asked me to swap out the scope. Once I removed the rings it was obvious that they were not concentric with each other, leaving a very rough scar on the scope tube—a sign of movement that can potentially damage the scope. The movement may result from slight variances in action screw holes, scope base thicknesses or contours, or even the scope installation process. None of those conditions are fatal, and there is a course of action to account for them that really isn’t difficult—lapping the scope’s rings.

It doesn’t take a lot of time to go the extra mile to lap, or true, the scope’s rings to each other. In about 30 minutes of carefully working a lapping rod and grit back and forth between the rings, you’ll have a platform that, despite any inherent inconsistencies, is now mechanically true and should accommodate the scope’s body tube without imparting stress. For this project I used the Weaver Optics Deluxe Scope Mounting Kit ($145) that contains all of the tools needed to properly lap rings and securely mount a scope with a 1" tube body including an instructional DVD.

There are other lapping and mounting kits available on today’s market, and they can be found online via a quick search. Regardless of which one you choose, taking the time to lap rings is likely to result in better shooting.