Self-loading rifles of bullpup configuration, in which the firing mechanism lies behind the pistol grip, are in use worldwide among militaries and, in semi-automatic form, are gaining in popularity among American shooters. The major advantage of the bullpup concept is compact overall size relative to barrel length.

The 5.56 mm NATO-chambered K&M Arms M17S reviewed here is somewhat unusual in that it is entirely U.S.-made and features nearly all-metal construction. It began as a circa-1978 Australian design with unique elements that were later incorporated into a version sold in the United States by Bushmaster until 2005. Eventually, aerospace machinist Ken McAlister, who had been repairing and modifying his own and friends’ examples, began manufacturing the improved version sold today.

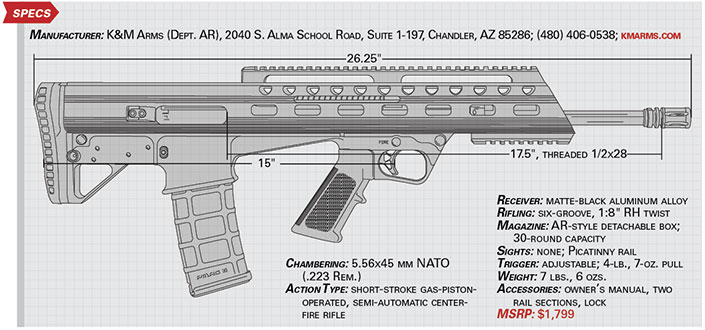

The M17S is immediately distinctive for its use of a 21 1/2"-long aluminum combination upper receiver/handguard and its 16 1/2"-long, one-piece, machined-aluminum lower receiver, which is the serialized component. The former has a trapezoidal cross section that measures 2¼" in width at the bottom and 1¾" in width at the top. A series of holes—rectangular ones along each side, and circular ones along each upper corner and in the top forward section—aid cooling of the rifle’s operating mechanism and reduce weight. A 12½"-long section of Picatinny rail is bolted to the upper, allowing for the mounting of iron and/or optical sights. A 4¼" section of rail is bolted to the upper’s bottom front surface to facilitate the attachment of a bipod or foregrip. Two additional sections of rail measuring 27⁄8" in length are included with T-nuts that mate with slots on the upper’s sides, allowing the attachment of accessories.

Two of three sets of crossdrilled lugs, machined integrally with the upper, protrude downward to mate with captive cross pins at the lower’s front and rear. A gas block located about 7" from the muzzle, and affixed to the upper with two screws, and a breech block keyed to a slot in the upper and affixed with a large cap screw secure the barrel to the upper. The breech block has two passageways above the barrel that orient the front of the twin recoil spring guide rods. Slots in each side of the upper allow the charging handle to be installed on either side. The bolt carrier can be withdrawn from the rear of the upper after pushing out the takedown pin and pivoting the upper away from the lower. The bolt itself features three locking lugs and is cammed in and out of engagement by way of a cross pin acting on a kidney cut in its body. A tappet rod extending from the gas block through the top center of the breechblock acts directly on the bolt carrier to drive it rearward, unlocking the bolt and causing a hook extractor, mounted at 9 o’clock, and plunger ejector, mounted at 3 o’clock, in the recessed bolt face to send a spent cartridge case free of the gun on its right side. A case deflector is mounted with two screws at the rear of the ejection port. There is no provision for ejection from the left side. A rubber buffer in front of a plate at the rear of the guide rods cushions the bolt carrier’s blow as it is driven rearward. The carrier is returned by the recoil springs, which cause the bolt head to strip a new cartridge from the magazine before chambering it and locking back into battery.

The lower incorporates a generous trigger guard with a skeletonized, adjustable, pivoting aluminum trigger above which lies a crossbolt safety that is pushed from right to left to fire. The A2-style pistol grip can be replaced with most AR-compatible models. The mouth of the magazine well is generously flared, and bilateral releases are positioned at its rear. A bolt hold-open/release is located immediately above the left-side magazine release button. Sling swivel cups are located on the lower immediately in front of a separate metal buttplate to which a Magpul rubber buttpad is affixed with two screws. A passageway inside the lower accommodates a 12¼"-long round wire trigger bar connected to a modular Elftmann trigger pack held in the lower by way of two AR-style push pins.

Initial impressions of the M17S were positive thanks to its streamlined shape and a balance point behind the pistol grip that made holding it in a firing position, with the butt tucked into the shoulder pocket, easy using the firing hand alone. Most shooters were able to come to terms with the rifle’s somewhat unconventional manual of arms rather quickly. The trigger, which exhibited a 4-lb., 7-oz. pull, was the best we have experienced on a stock factory bullpup rifle. We fitted the gun with a compact Trijicon ACOG TA44S-10, a 1.5X 16 mm optic, for close-range shooting drills, although accuracy testing was conducted with a Leupold Mark AR MOD 1 3-9X 40 mm riflescope.

In more than 300 rounds of firing, the rifle exhibited reliable functioning, save one stovepiped case, and accuracy results were entirely acceptable given its intended use. The gun did exhibit somewhat harsh recoil considering its mild chambering, and the bolt handle proved rather difficult to withdraw owing to the heavily sprung bolt carrier group and the charging knob’s minimal dimensions.

We see the M17S as filling a niche for users who place a premium on a self-defense rifle of carbine length that can be transported, stored and pressed into service without having to retract or fold a buttstock. And while its appearance and manual of arms can be off-putting to those who have mastered more common platforms, its compactness is an advantage that is difficult to dismiss. For shooters seeking an all-U.S.-made, all-metal bullpup rifle, the K&M Arms M17S stands alone.