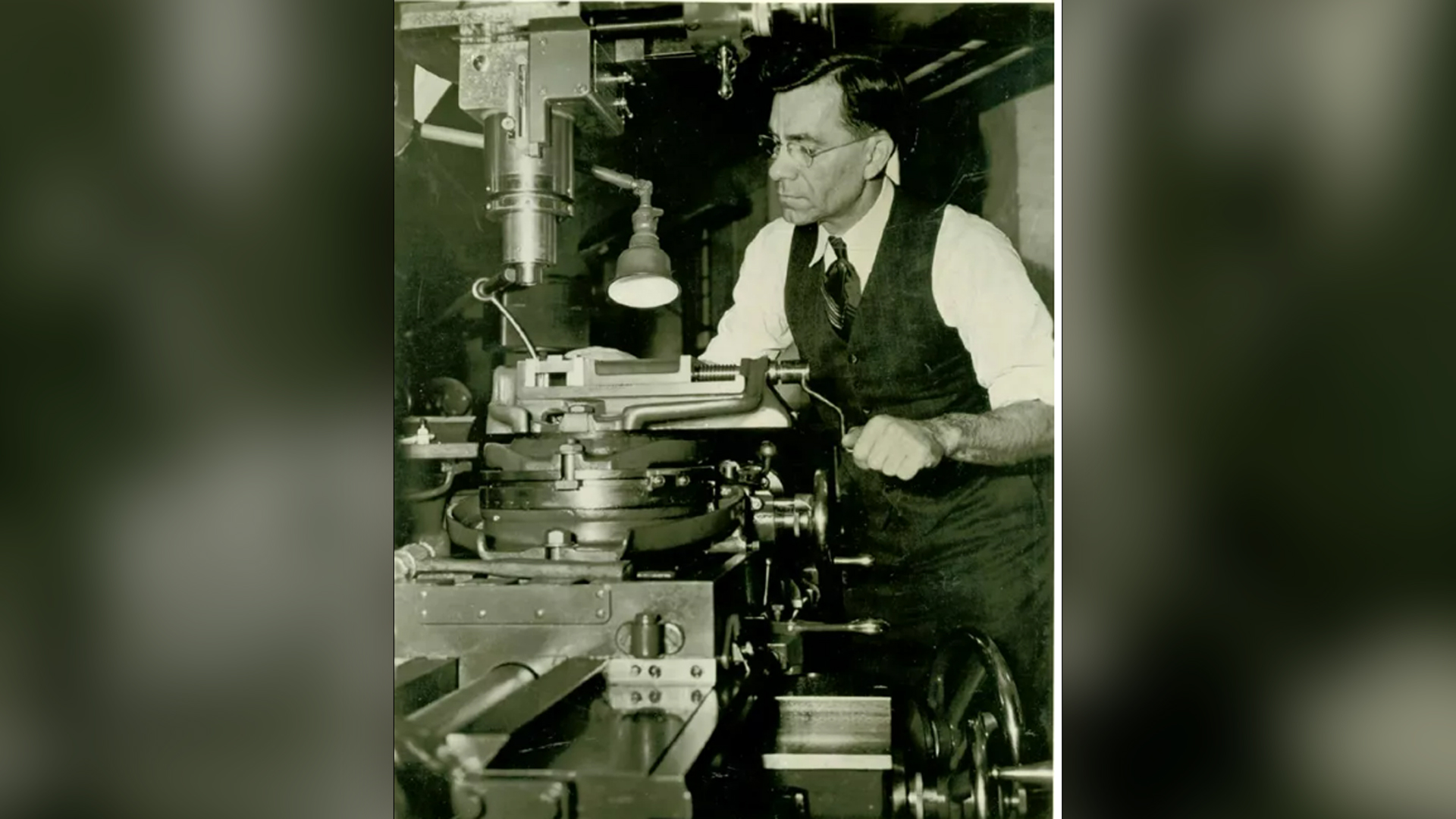

John C. Garand has earned his spot among the most legendary arms designers in history. His name is synonymous with innovation. But often, the question is asked, “Why did John Garand, who revolutionized the United States military with his creation, not get paid royalties?” The truth is that the U.S. government compensated Garand well for the services he rendered, but to review his rewards, it’s important to understand his career path.

Early Life

Born January 1888, in Quebec, Canada, to a family with 11 other siblings. His father and mother had six boys and six girls. When John Garand’s mother died in 1899, their father moved to Connecticut. He grew up mainly working in a textile mill or toolmaking company, where he learned his love of firearms and machine work. He would take a job as a firearm engineer at none other than Springfield Armory in Springfield, Mass., on Nov. 4, 1919. He was well on his path to making his mark in history.

There, he was tasked with designing a basic gas-actuated self-loading rifle. The Army had been interested in developing a semi-automatic infantry rifle and had some prototypes in development as early as the turn of the century, but unfortunately, it could not get any of them to work. However, with John Garand’s love of shooting and machine work, his ingenuity was able to run wild. He would stay as an employee of Springfield Armory until his retirement in 1953.

Garand’s Career Progression & Salary

Given Garand’s natural aptitude in machine work and firearm design, it would not take long for him to excel in the Ordnance Dept. The reader should note his starting salary in 1919 ($1,800) as a Master Gauge Expert with the Bureau of Standards and his salary in 1942 ($8,000) as Chief Engineer at Springfield Armory.

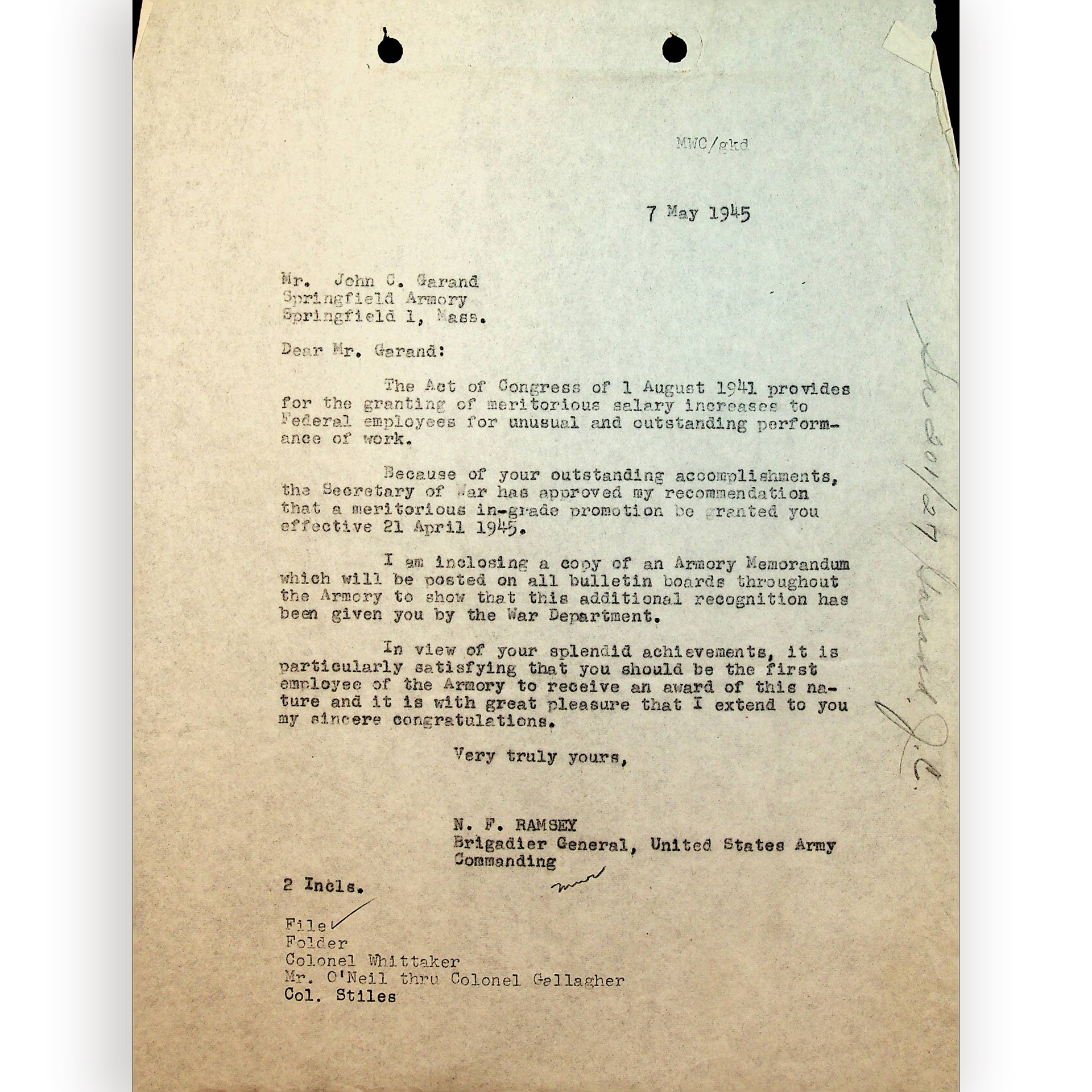

Adjusting for inflation in 2024 to give the reader a modern-day comparison, Garand started out at $34,417 and, over the course of 23 years, received pay increases and salaries to the price point of $160,760. One should never forget that his rapid progression during the Great Depression is a testament to his aptitude and work ethic. The last entry noted on the table below on April 14, 1945, was not a promotion but an in-grade salary increase from $8,000 to $8,250 for his excellent work in the Ordnance Dept., approved by the War Dept. to reward civilian employees for meritorious service.

|

Job Description |

Salary |

Assignment |

Date |

Remarks |

|

Master Gauge Expert |

$1,800 |

Bureau of Standards |

8/16/1918 |

Entered |

|

Master Gauge Expert |

$1,800 |

Bureau of Standards |

8/31/1919 |

Terminated |

|

Mechanic |

$2,400 |

Bureau of Standards |

9/29/1919 |

Entered |

|

Mechanic |

$2,400 |

Bureau of Standards |

10/22/1919 |

Terminated |

|

Skilled Laborer |

$300 (monthly) |

Springfield Armory |

11/4/1919 |

Entered |

|

Auto. Rifle Designer |

$3,600 |

Springfield Armory |

8/17/1921 |

Promoted |

|

Auto. Rifle Designer |

$4,000 |

Springfield Armory |

11/29/1924 |

Promoted |

|

Auto. Rifle Designer |

$4,400 |

Springfield Armory |

7/1/1928 |

Promoted |

|

Ordnance Engineer |

$4,400 |

Springfield Armory |

7/1/1935 |

Promoted |

|

Senior Engineer |

$4,600 |

Springfield Armory |

1/23/1937 |

Promoted |

|

Senior Engineer |

$4,600 |

Springfield Armory |

3/30/1937 |

Promoted |

|

Senior Engineer |

$4,800 |

Springfield Armory |

4/27/1938 |

Promoted |

|

Senior Engineer |

$5,400 |

Springfield Armory |

6/6/1939 |

Promoted |

|

Principle Engineer |

$5,600 |

Springfield Armory |

8/16/1941 |

Promoted |

|

Head Engineer |

$6,500 |

Springfield Armory |

9/27/1941 |

Promoted |

|

Chief Engineer |

$8,000 |

Springfield Armory |

10/31/1942 |

Promoted |

|

Chief Engineer |

$8,250 |

Springfield Armory |

4/18/1945 |

Meritorious Within-Grade Salary Increase |

The Accomplishments Of John Garand

John Garand was primarily known for his work in developing the M1 semi-automatic rifle, which was subsequently adopted. But he made many other small but significant contributions. These often-overlooked improvements did have an interesting impact. On July 27, 1943, the superintendent of Springfield Armory, Col. Earl McFarland, wrote a letter to Miss Helen McCabe of the U.S. Civil Service Commission detailing many of Garand's contributions to the operations at Springfield Amory, both big and small:

Hammer Contour Profiling

Former Method: There are three profiling cuts in this operation. It was formerly done in two operations on a vertical profiling machine using two formers and one latch and hand-operated. This was a very slow method producing about 40 an hour.

New Method: Mr. Garand designed, and d built an ingenious 3 spindle, 10 station vertical profiling machine. The work is gripped in place by fingers that are cammed in and out of the rotating worktable and no manual effort is required to fasten the work on the fixture. The cutters are automatically cammed. This machine increased production did more accurate work, and was so successful the Kreuger Company were commissioned to build three along the same lines.

Chamber Honing

Former Method: Prior to this development, chambers were not honed but left reamed. However, in the case of a semi-automatic weapon like the Garand, it was felt that some treatment should be given to counteract the annular influence of a rotating reamer and thus facilitating extraction of the cartridge case.

New Method: A machine was outlined and the project turned over to the Joseph Alexander Carlin Company of Bala Cynwyd, PA. The machine was not entirely satisfactory, so it was rebuilt by Mr. Garand using about half as many parts. The original machine builder would not undertake to build a hone holder, so Mr. Garand designed and built one.

The principle of the honing process is essentially this: The barrel is held in a vertical chamber-down position of a spindle having both a rapid reciprocating and slow rotating motion. The spindle has two small fine hones along the opposite sides of the spindle and held out against the chamber sides by springs. The action of these hones gives a fine polish to the chamber and single the vigorous honing is lengthwise of the chamber the “Grain” of the polish surface helps shell extraction.

Barrel Threading For Gas Cylinder

Former Method: Originally a standard type of thread grinder was used. Such a machine costs around $12,000. It handled 50 barrels an hour. This machine developed threads concentric with the bore. It was found that they should be concentric with the outside of the circumference of the muzzle.

New Method: Mr. Garand designed and built a small simple semiautomatic machine that chases the thread accurately, and without the inaccuracies resulting from wear that are inherent in the other types. His design cuts the threads concentric with the outer circumference of the muzzle. He also developed grinders and gauges for chasers. The production of this machine is about 125 per hour.

Curved Follower Guide Slot

Former Method: These parallel slots, one of each inside wall of the receiver are approximately 2” long on a curve of about 2’ radius. These were formerly cut on a vertical shaper with a special head to cause the cutting tools to travel on an arc. Production was 100 per eight-hour day.

New Method: Mr. Garand believed, contrary to general opinion, that a harder breaching tool could be bent in an arc and open up a untried application of breaching. His plans of a machine were submitted to the Krueger Co. who were willing to undertake its construction. The result was the most successful. It was the first time an internal out was ever done on a curve of breaching, and raised the production per machine to 750 per eight-hour day.

Rod, Follower

Former Method: This was originally one forging required considerable machining.

New Method: Made in three stampings, assembled by riveting through the use of an ingenious device for aligning the parts and setting the rivets in one operation. Production was increased five hundred percent. Forging capacity was released. Material was saved/ A compensator spring was dispensed with.

Sear

Former Method: The sear was made from drawn stock, then out of.

New Method: A continuous milling process was devised resulting in greater precision and decreased malfunctioning due to incorrect timing.

Operating Rod Pistol

The work head on the Fitchburg Grinder was rebuilt to expedite grinding of the Operating Rod Piston. Production was increased three hundred percent, and scrap reduced by eight percent.

Spring Gauge

The proper performance of an automatic firearm depends on the uniform action of its helical springs. It is essential to know that springs compress exact amounts under known weights. Mr. Garand developed an instrument for gauging springs accurately. It is built now by the Federal Products Corporation and widely used in industry.

Bolt Locking Lugs

The head on the Browne & Sharpe Grinder was redesigned to give better finish and greater precision.

Bolt, Operation 7

Former Method: This involved several cuts on each end of the bolt. To produce fifty pieces per hour, there were required:

- 7 Turret Lathes

- 6 Engine Lathes

- 3, 6x18 Cylinder Grinders

- 4, 3-Spindle Drill Presses

- 2 Hand fixtures

- 22 Operators

New Method: As a result of Mr. Garand’s ideas, a special two-way horizontal machine was built, having ten fixtures and nineteen tool holders, with forty-seven cutting tools. It is automatic and operated by one operator. It produces eighty pieces per hour.

Grenade Thrower

Mr. Garand’s design was adopted by the Army and is now in production.

In addition to the above, Mr. Garand has devised numerous methods, tools and gauges. He has designed four, built three, Semi-Automatic, .30 Caliber Carbines, one of which went through the final rounds of test. He has designed and practically completed a model of a new .60 Caliber Anti-Tank Gun.

Colonel MacFarland did his best to summarize Garand's contributions at Springfield Armory without getting overly technical. Even with zero experience in machine work, firearms design, or production, the reader can take away a general overview of his contributions. Garand simplified existing practices, increased production, decreased waste and increased efficiency. He created solutions to problems that previously were thought not to be possible.

The economic hardships of the interwar period should be noted. After the demobilization of the U.S. armed forces following the First World War, the U.S. found itself in an unusual situation: a seemingly endless supply of small arms that could be placed in war reserve, ready for the next crisis. The U.S. economy suffered from back-to-back recessions followed by the Great Depression. Bearing this in mind, funding for the U.S. military was challenging to obtain, so Garand's innovations to stretch funding, reduce waste and increase efficiency were a dream come true for Springfield Armory. It did not go unappreciated.

Recognition

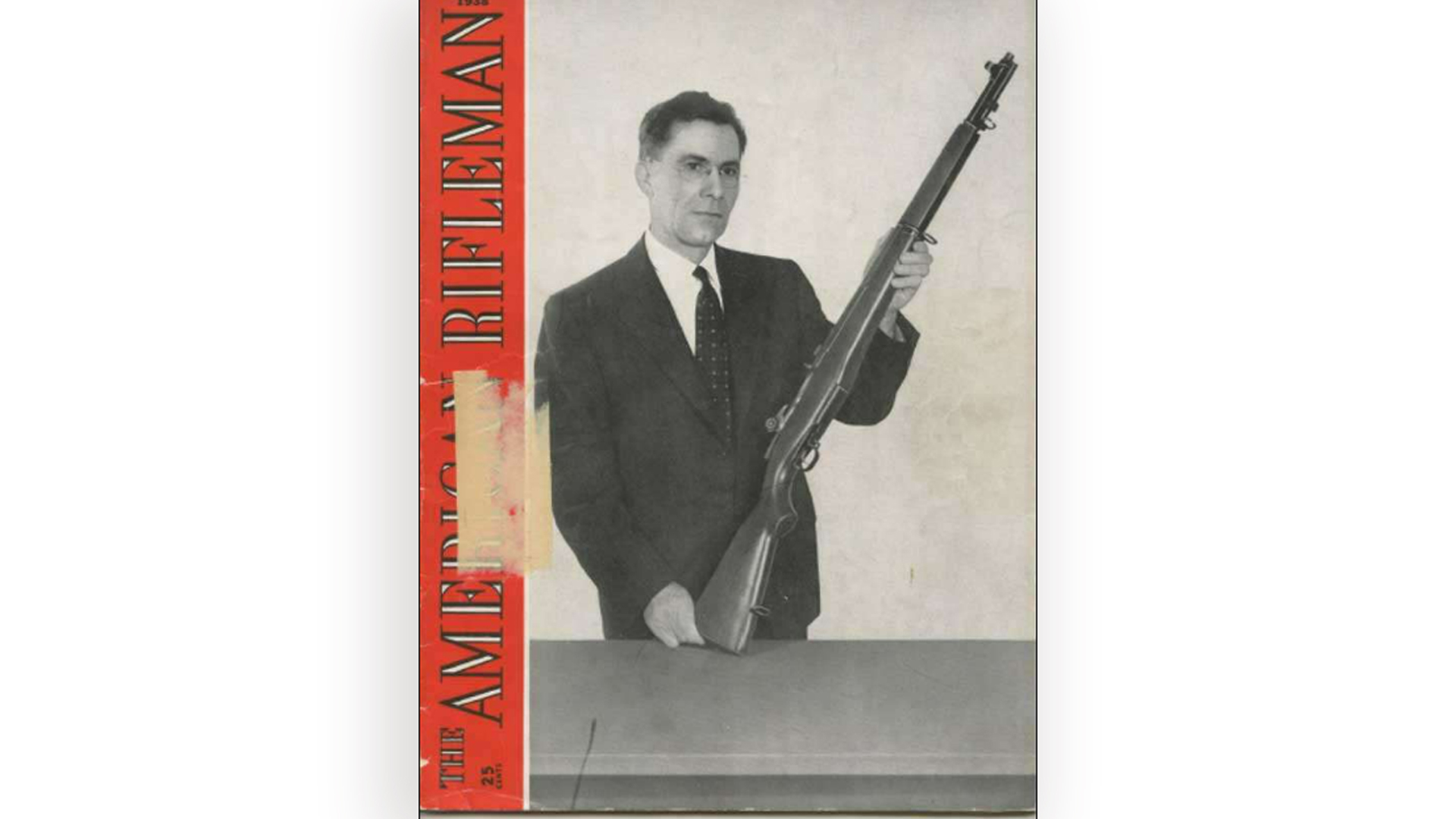

Following the adoption of the M1, Garand was becoming a household name, and award nominations and interview requests would soon follow. In December 1939, Col. G.H. Stewart was notified by the staff secretary J.C. Patterson of the National Modern Pioneers Committee that John Garand was nominated for the Modern Pioneer Award for his development of the M1 rifle. Also, in 1939, Garand was awarded the Pynchon Medal by the Advertising Club of Springfield, that region's oldest public service award. Most particularly interesting is that, in addition to the rifle's contribution to the country's national defense, as noted by so many others, it also notes the following in the citation:

"The production of this rifle has substantially relieved unemployment in Springfield and nearby cities. A commercial organization's production in New Haven will also create considerable employment."

One of the most overlooked aspects and contributions of the M1 rifle is its economic impact on the New England region. When unemployment was staggering, it provided much-welcomed relief in the form of stable employment for the area's residents.

In September 1941, the American Society of Mechanical Engineers announced that John Garand would be the recipient of the Holley Medal for 1941: "In recognition of your invention and development of the semi-automatic rifle, which bears your name and has been adopted by the U.S. Army, a distinct contribution for our national defense." This was a prestigious award awarded to other innovative inventors, such as Henry Ford for his work on mass transportation and mass production methods and Frances Hodgkinson's meritorious services in developing the steam engine.

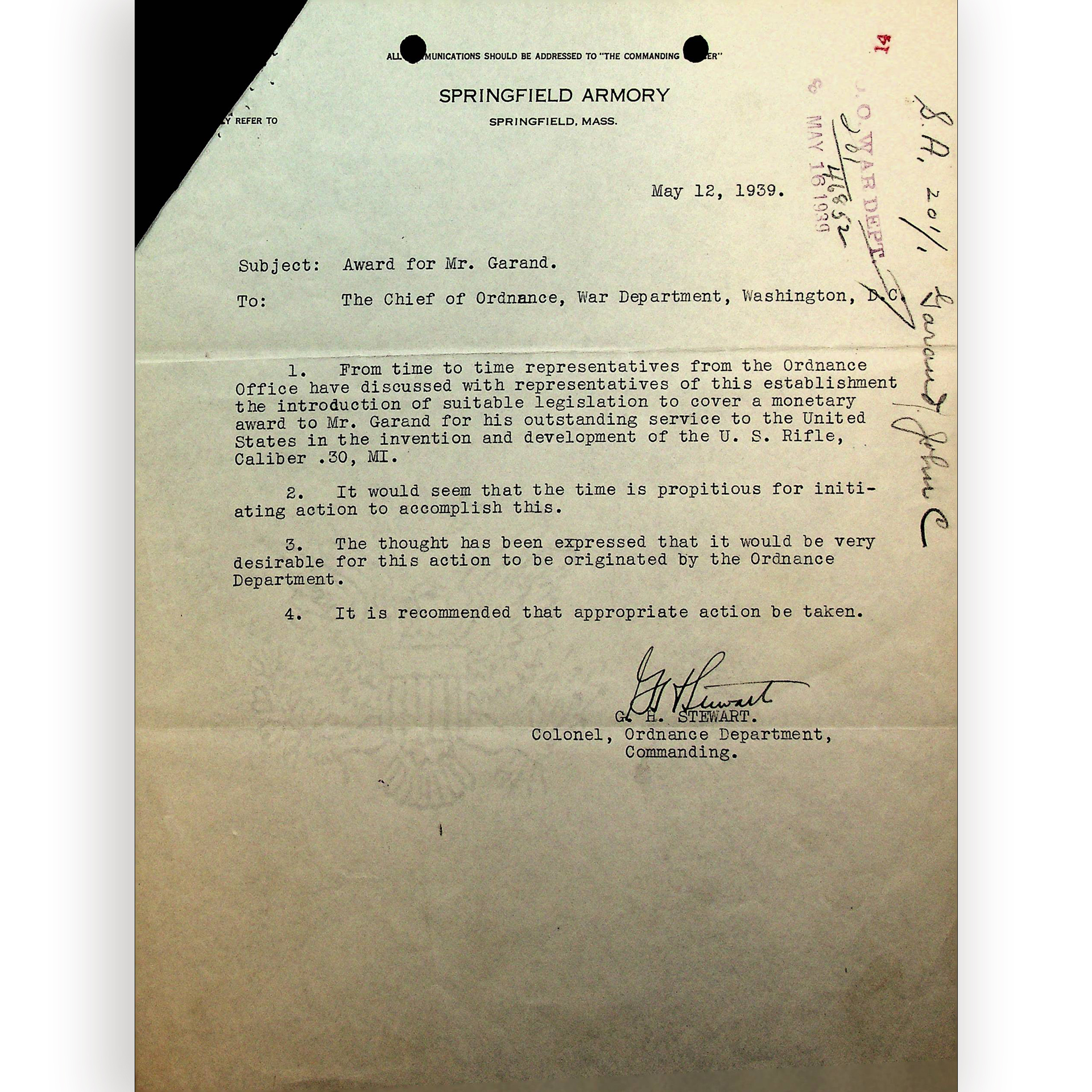

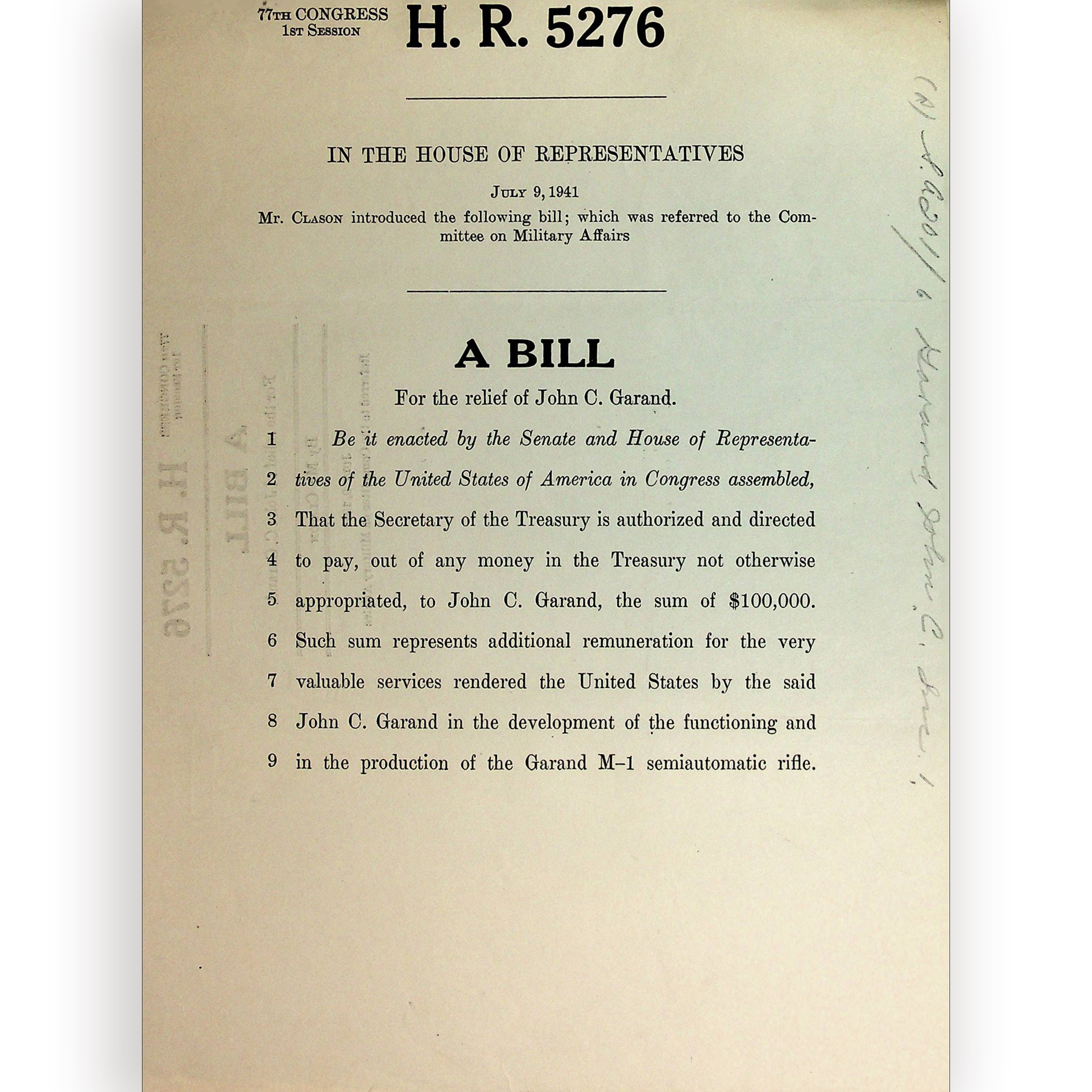

Although awards of recognition likely were welcomed by Garand, his most substantial award came from the efforts of Col. G.H. Stewart in 1939 when he notified the Chief of Ordnance that the time was appropriate to nominate Mr. Garand with a monetary award for his invention. It would take some time, as most legislation through Congress does. Still, on July 9, 1941, H.R. Rep. Charles Clason (R-MA) introduced the following bill to Congress:

A Bill For the Relief of John C. Garand

Be it enacted by the Senate and House of Representatives of the United States of America in Congress assembled, That the Secretary of the Treasury be authorized and directed to pay, out any money in the Treasury not otherwise appropriated, to John C. Garand, the sum of $100,000. Such sum represents additional remuneration for the very valuable services rendered to the United States by the said John C. Garand in the development of the functioning and in the production of the Garand M-1 semiautomatic rifle.

While it is not a royalty payment, adjusted for inflation $100,000 in 1941 equates to roughly $2.2 million dollars. Unfortunately, the bill did not pass. It should be noted that, in 1944, the attorney general noted that Mr. Garand was the highest-paid engineer during his entire tenure at Springfield Armory. Garand had been one of the highest-paid employees at the Armory since the beginning of his employment. Given that it was well-known exactly how well-compensated he was as a public servant during the Great Depression, that may have contributed to the politicians in Washington not voting in favor of the bill.

Garand's Legacy

John C. Garand is the story of legends. He came to this country from a poor immigrant family from Quebec, Canada, after losing his mother. He took an early job sweeping floors of a textile shop and found a love of firearms and machine work. Combining the two, he revolutionized the U.S. firearm industry and the U.S. military by developing the first semi-automatic rifle adopted by the U.S. military, a desire of the Army going back to the era of the Krag. However, his contributions weren't limited to the rifle alone; he saw problems in rifle production and found creative solutions that streamlined production, increased output and efficiency and decreased waste. He could discover unconventional solutions at Springfield Armory, sometimes considered unfeasible, and make them work. In addition, his inventions also contributed to helping put residents of the New England area back to work when that was no easy task. Although Garand was not boastful, his work did not go unappreciated, and nor was it taken for granted.