Back in the day, Federal was the RC Cola of the ammo business. Not Coke, not Pepsi, the company founded in 1922 by Charles Horn plugged along in third behind a couple of brands better known for making guns.

But as I said, that was a long time ago; so far back that generations of shooters will find it puzzling given Federal’s current high profile in terms of shelf space, government contracts, media splash, product innovation and other metrics. In my observation, it dominates big-game, leads or is close to it in handgun and shotshells, outpaces rivals in certain competition disciplines, and grabs a huge share of practice and plinking sales.

Nonetheless, I was surprised to learn about a couple recent developments. First, Federal, along with affiliates Speer and CCI, are not just overall leaders in market share—they hold that spot by a solid margin thanks to being number one in rifle, handgun, shotshell and rimfire categories, plus number one in law-enforcement sales (2017 data from National Shooting Sports Foundation). Which makes the second revelation even stranger: The company is now toiling to revamp its public image. Being number one with a bunch of bullets (pun intended) apparently isn’t good enough.

To get to the bottom of this, I journeyed to company headquarters in Anoka, Minn., a memorable experience even in my long, eventful NRA career. It wasn’t my first visit there, but it was the first occurring in the dead of winter. And true to form: zero degrees, whiteout snowstorm. Where I come from that would rate as an Arctic Apocalypse, but my hosts and their fellow Minnesotans seemed largely unconcerned.

But not even a blizzard could top this declaration from Director of Marketing Jason Nash: “We’re not going to be this modest, little Midwestern company any more. We’re not going to be jerks about it, but we are proud and are going to talk about the fact that we’re the world’s number-one ammunition maker.” A joke, sure, but also truth spoken in jest. Part of the irony is that Nash is the dictionary example of a polite, measured Midwesterner. Partly it’s that Federal has long been an exemplary corporate citizen whose generous support has buoyed worthy causes ranging from youth shooting to wildlife conservation to Olympic teams to NRA advocacy and myriad others. And partly it’s Federal’s penchant for doing business with its competitors, in ways visible to consumers and ways not so apparent.

None of that will change, so just what was all this about the good-guy Midwesterners striving for even greater success by playing rougher?

Taking The Reins

Not messing around, I posed the obvious question to President of Ammunition Jason Vanderbrink: “Why rebrand or change now when you’re already number one?”

He didn’t blink. “Eight years of plenty—the Obama years—made many people in our industry very complacent. Complacency kills innovation and complacency kills companies. So we are never going to be complacent as long as I have something to say about it.”

Now in his second year leading the charge, Vanderbrink isn’t a new guy, having advanced through the sales ranks before his promotion. I soon learned he appreciates accurate rifles, is a mule deer fanatic, displays a jaw-dropping collection of autographed baseballs in his office and was talking about taking his seven-year-old daughter ice-fishing the wintry day I interviewed him. As a Michigan farmboy, Vanderbrink was a junior sporting clays champ and sowed the seeds of brand loyalty using Federal Premium .280s in his deer rifle. My first impression was that he’d be a great partner in hunting camp, at a tailgate or just talking guns, thus echoing his staff’s consensus—guys I’ve known and worked with for years—that JVB is a great fit.

Along the way, hard work earned him what some gun-industry folks consider a doomsday account: Walmart. The retail giant is known for ruthlessly leveraging its volume clout to beat down margins so thin that suppliers can barely eke out a profit. But not Vanderbrink, who actually moved to Arkansas to open a company office. “Working there really got me ready for this job. Walmart makes you look at analytical stuff all the way down to revenue per square inch. I’m now responsible for sales, marketing, finance, management, all at the same time. Business is my passion, it’s what got me to his point.”

Upon taking the reins, Vanderbrink looked beyond the bottom line to find a company suffering a kind of identity crisis. Despite a bevy of solid sub-brands, including Fusion, Speer, CCI and Alliant Powder, the operation had become overly dependent on its flagship, Federal Premium. “We were putting ‘Premium’ on stuff that shouldn’t have been Premium, and with overuse it had become very vanilla,” he said. “Federal Premium has to be a sub-brand under Federal, and only the absolute best product can bear the Premium name. If you call practically everything ‘Premium,’ then what really is?”

That realization seeks to reverse a long-time drift. Fifty-two years ago, Federal began its climb out of third place with the advent of Premium. The bright idea was to sell handload-quality big-game loads, and the topper, literally and figuratively, was to feature custom bullets previously unavailable in factory ammunition. First up were Nosler Partitions and Sierra GameKings. In following years, Premium could be had bearing coveted heads from Trophy Bonded, Speer, Barnes, Swift and Woodleigh. Further customizing included nickel-plated cases and sealed primers. Riflemen responded in droves and chose Federal Premium.

In time the concept spread to match loads, rimfire, pistol ammunition and shotshells. By 2000, Federal Premium spanned all ammunition categories with scores of products. By then, Federal was no longer America’s third-place ammunition maker.

Communicating With Shooters

“One thing I saw was that our packaging lacked a clear theme and Premium was overused,” Vanderbrink said. “End users need to know what our brands mean. They need to recognize them on the shelf. Premium has to have the best packaging—a Ferrari has to look like a Ferrari.” Later I heard a parallel conclusion coming from another direction. “It’s important for our American Eagle (budget) brand to have a complementary look,” said Senior Product Manager Mike Holm. “For a customer who decides he doesn’t want to pay for Premium, the new American Eagle packaging clearly comes from the same place and the product comes from the same factory. The customer expects it too will perform at a high level.”

To rebuild brand identities the company is changing what the public sees via retail packaging, advertising, apparel and elsewhere. The shift comes with big expectations. “We want customers to feel a sense of pride when they pull our box off the shelf, to feel confident they now have a quality product,” Nash said. He used terms like “aspirational” and “informative” to explain intentions for the new look and emphasized, “Federal had to be more prominent on the box than before.”

That echoed a comment from Vanderbrink, “The Federal brand is going on 100 years old. It can stand proud. Our old packaging was confusing—but we’re fixing that.”

Certainly the new stuff is stylish and fresh. The design layers multiple elements—some literal, like a bull elk or AR-type rifle—some suggestive, such as silhouettes of flying ducks or a shattering claybird. Plus there’s an abstract marker common to the entire portfolio—a graphic shockwave. Representing projectile flight, these concentric arcs—three of them—prompt us to intuit ammunition at work. On the new boxes, large, opaque shockwaves overprint the more literal elements. Front panels provide key bits of info: chambering in big type in the upper left; bullet details in the lower right; country of origin—always the USA—bannered by Old Glory in the upper right corner. That’s a lot, but somehow it’s not cluttered. Elsewhere the boxes offer ballistic data and often cutaway art that shows internal construction of the cartridge and the bullet or pellets. End flaps present priority identifiers to ease point-of-purchase decisions.

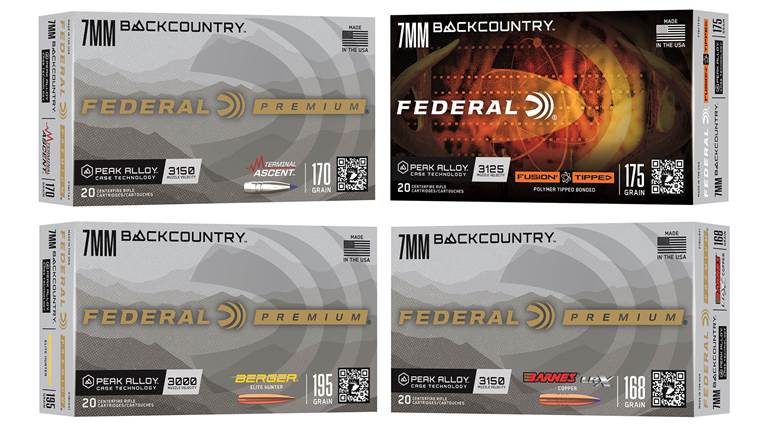

A recurring color palette will help differentiate between sub-brands and lines. Premium is mostly black or gray and trimmed with ritzy gold-foil. Mid-tier house brands like Power-Shok, Top-Gun Sporting and Champion rimfire come dressed in blue. Fusion remains in orange livery, and American Eagle sports red hues. Certain lines don’t strictly conform; for example, Syntech boxes now color-coordinate with the polymer jackets specific to each product. All this remains a work in progress, and not all of the hundreds of Federal SKUs have transitioned to the new look, though Nash assured that’s coming.

Such a massive effort necessarily involved top management plus marketing and sales pros working with talented graphic artists. Add to that another uniquely qualified consultant who kindly stopped by during my visit. I met David “Doc” Fredrickson four years ago, shortly after he was named the company’s “unofficial historian” and wrote a website article about his incredible collection of everything Federal. The man is both an interesting character and a genuine American hero, and I urge everyone to read his story at: americanrifleman.org/superfederalcollector.

Doc also—I feel safe to say—knows more about Federal packaging than anyone who’s ever lived, and so give credit to the current leadership for seeking his input. With perspective that goes back to the very first shotshell boxes from the early 1920s, he told me he favors those that clearly depict game animals, and that he highly approves of the new packaging’s imagery of deer, elk, turkeys, coyotes and more. Apart from increased sales, I don’t know how you’d get a better endorsement.

Part of the reason Doc came in was to bring historic boxes for a new tribute wall slated for the Anoka facility’s entrance building. On display will be a packaging timeline from the start to present day. Erected this spring, visitors can’t help but notice the colorful, fascinating evolution of the historic factory’s output. However, don’t think Doc walked out empty-handed, not with all this new packaging coming online.

The catch phrase around the rebranding is “The New Look of Authority.” Nash said that besides the obvious, it plays on the word Federal. But as I toured the offices, factory and QC labs that make up the vast home base, I kept hearing an additional take. Not just that it has the best products, but that Federal is the best at loading ammunition. Naturally those attributes go hand-in-hand but the distinction surpasses what media and consumers normally focus on. Though it’s easy to dote on prime components, anyone who’s done even a little handloading knows the real magic is in the loading technique that produces round-to-round uniformity. More than anything, that determines how well handloads and factory loads perform. Federal believes they’re the best at that and the current management wants you to know it.

Vanderbrink let me know by bragging up his workforce. “[In this economy] it’s been tough hiring new workers,” said Vanderbrink, “but it’s getting better, and keep in mind our average tenure exceeds 10 years and many employees are at 20-plus. They view it as a career. As some competitors’ factories went south, Federal repeatedly doubled-down and spent millions staying here in Minnesota. As you’re seeing, our employees wear their Federal gear to work and take pride in building the finest ammunition.”

At my prompting, he shared an example of their dedication. “During this winter’s infamous polar vortex, with temperatures in the -30s, wind-chills at -55 °F, the city shut us off of natural gas because of shortages to residential neighborhoods,” he explained. “We have propane backup, but in weather like that, propane freezes. So our maintenance crew had to be out in it throughout the night, thawing out propane so we could keep running.

“People get tired hearing me say it,” Vanderbrink continued, “but the management and back office here are a service organization to the factory. At the end of the day, the workers run this company, and we depend on them to make the best products in the world. My job is to support them all the way.”

Delivering The Goods

I bet virtually no one reading this believes their purchase decisions are much influenced by package design. We know how knowledgeable American Rifleman readers are because you hold us accountable page by page. We know your technical savvy is balanced by common sense, and so if packaging talk leaves you a bit skeptical, understand that’s only part of our story. The other part is that a company so motivated to call attention to itself from folks who appreciate the difference between real performance and hype, better have superior products no matter how informational, aspirational or stylish its packaging is.

And so during my visit, I grilled Vice President of Product Development Drew Goodlin and his engineers, plus product managers led by Holm and Rick Stoeckel, about a bevy of introductions—among a total of 60 during the past two years—that have impressed us as genuine solutions or improvements.

Here’s a look at a handful of our favorite new offerings:

• Though Catalyst has been on the market for five years, Federal soft-pedaled the rollout of this lead-free primer developed in response to multiple requests. “Customers and indoor ranges wanted alternatives to existing lead-free primers that weren’t robust, and the U.S. government, too,” recalled Goodlin. “That led to Catalyst, our duty-worthy, lead-free product; we call it ‘heavy-metal free.’ Actually, it was a quest to find a better primer. We took it way beyond the original goal, and you don’t give up anything comparing this technology to the world’s best primers. It’s also safer to manufacture, and Catalyst performance is proving exceptionally consistent and versatile.” To prove the point, these next-gen primers are not only found in Syntech handgun ammunition, but also in Black Cloud and BallistiClean shotshells.

• At first, demand was slow. Syntech Range combined polymer-coated bullets and leadless primers to answer customers and ranges seeking clean indoor practice rounds. Then came Syntech Defense, same Total Jacket, but now over a segmenting hollow-point for dynamic terminal performance. “It was clear to us what we had,” recalled Nash, “but it took a couple years to get shooters to use it.” Now sales are booming, and the coating has been applied to other specialties, including Pistol-Caliber Carbine, Action Pistol and Training Match.

“Development of the jacket required a ton of science. But the difficult part was learning how to make it affordable,” Goodlin said. “We did, and people like different colors indicating what the load is for, smooth feeding because the jacket acts like a lubricant, and as far as safety, splash-back from Syntech is next to nothing.”

• “Customers want to push their ARs to longer ranges, but after looking at a lot of possibilities, we came back to .224" as the most practical [bullet diameter],” Drew Goodlin said, referring to Federal’s .224 Valkyrie cartridge. “Great ballistics and many great bullet choices. So we switched focus to looking for the biggest practical case, which got us to the 6.8 mm SPC. We backed down the shoulder to accommodate longer bullets, and that was it.”

The result was a new chambering designed to appeal to both AR and bolt-action shooters. “We stumbled a bit on twist rates—but now know 1:6.5" or 1:7" is best for the heavier 90-gr. bullets,” Goodlin said. “The kinks have been worked out.”

• “Many shooters don’t know that .22 rimfire is more than just .22 Long Rifle. It used to be .22 Long, .22 Short and, the smallest, .22 CB,” Goodlin said. “Quiet-22s are just CB components in a .22 LR case, with CB noise levels. Not exactly magic, but unlike the little CBs, they will cycle in different actions.

“Now we’ve adapted the concept for those shooting 10/22s. We found that a 45-gr. bullet at slightly more velocity reliably cycles the action, and while a little louder, is still highly shootable without hearing protection.”

• “The Edge TLR bullet is based on Trophy Bonded—it’s bonded, too—but the geometry is different,” Goodlin stated. “The bonding keeps it together for deep penetration at all practical ranges, yet we had to design it to expand at faster and slower velocities. Our single AccuChannel groove on the bullet’s shank doesn’t cause the five percent BC drop you see with other grooving. The Slipstream polymer tip, which we’ve patented, is unique in how well it controls expansion. The Edge is about long-range—it’s a combination long-range target bullet and hunting bullet.”

• “Original Hydra-Shok is still extremely popular, but with Hydra-Shok Deep, obviously we designed for greater penetration,” Goodlin said. “Deep is actually more like our HST handgun projectile—very advanced skivving, but it has a tough central Power Post and core that make it better going through clothing and other barriers. In test media, our goal was 20" of penetration with controlled upset.” The 2018 introduction has been so well-received it won a Golden Bullseye Award from NRA’s Shooting Illustrated magazine.

• “We didn’t develop Tungsten Super Shot,” acknowledged Nash, “but liked what we saw, loaded it, and doing so made that technology far more available.”

“We launched Heavyweight TSS for turkey—small pellets whose high density makes them perform like bigger shot, except more of them hit the bird,” commented Goodlin. “For our waterfowl load—Black Cloud—we came up with TSS blends that make it affordable and yet deliver plenty of power to bring down geese.”

• A new packaging gambit, BYOB means just what you’d think: Bring Your Own Bottle or Bring Your Own Bucket. While contents of bottles and buckets normally meant by that acronym are anathemas in responsible shooting, not so here. Instead of adult beverages, we’re talking about Federal Champion rimfire ammunition in bulk quantities.

Vanderbrink told how the idea for the bottle came from a heads-up employee. “One of our Canadian salesmen was out shooting gophers, and called in to suggest putting .22s in a package that would fit his pickup’s cupholder. Cool, idea, huh?”

• Though it’s not an actual sub-brand and certainly isn’t new in any sense, the company is ramping-up Premium center-fire hunting loads by adding more designer bullets in a wider array of cartridges than ever. “If you look at this year,” said Vanderbrink, “we’ve brought on Berger and Hornady V-Max. Brought back the Barnes TSX, even though we offer our Trophy Copper. We set aside our pride and whatever bullets customers want, we do our best to offer it.” The Premium lineup now includes seven different non-Federal bullet brands, also including Sierra, Nosler, Swift and Woodleigh.

Vanderbrink summed up the company’s most recent efforts this way: “We love competition because it makes everyone better. It’s making us more aggressive, making us think outside the box and spend more on R&D. But it has to start with the customer and work backwards, and that starts with the packaging customers see when they pull our boxes off the shelf.”

Federal: Three Things You Didn’t Know

Here are a few insider bits I learned during my recent visit to the Federal Cartridge Co. facility in Anoka, Minn.

Inside Jobs—The company is currently building two new shops within its 700,000-sq.-ft. campus, both slated for operation later this year. One is a new primer-production area, necessitated in part by demand for the innovative Catalyst primer profiled on p. 72. Making primers—Federal’s output is more than a billion units annually—is the riskiest step in fabricating ammunition, and so the new facility will benefit from state-of-the-art safety design and equipment.

Also coming is an industry first: a custom ammunition shop. Several big firearm manufacturers operate prestigious custom shops, but not so for major ammunition loaders. Federal will soon announce specifics, but expect them to include rifle, pistol and shotshell rounds fine-tuned to customer guns—plus non-catalog loads incorporating preferred components from Federal and other brands. Senior Operations Director Erik Carlson said top employees are vying for custom-shop jobs.

Arms & Architecture—In 1954, the company helped finance the hometown Anoka City Hall. Is it a coincidence that the building looks a bit like a handgun when viewed from above? Check out the satellite image.

Advocacy—Company founder Charles Horn was a leading voice for passage of the Pittman–Robertson Federal Aid in Wildlife Restoration Act, the cornerstone of American hunting for nearly a century. Echoing that, parent company Vista Outdoor now employs a full-time lobbyist. Based in Washington, Fred Ferguson works closely with NRA-ILA on federal and state-level issues on behalf of America’s gun owners and hunters. Recent accomplishments include: amending the migratory-bird framework to allow states to extend duck seasons to January 31 (as opposed to the last Sunday in January); convincing the states of Utah and Nevada to allow shot smaller than No. 6 and/or .410-bore shotguns for spring turkey, thus making it legal for hunters to use the new TSS loads from Federal and other companies.