Widely acclaimed as one of the best quality sidearms produced before World War II, the Vis 35 (or Radom, as it is commonly known—the name coming from the factory where it was made) was the third most common service pistol used by the German military during World War II. It is largely based on the Browning High Power, with the addition of a grip safety and a decocking lever. It has an eight-round, single-stack magazine and is chambered for the standard 9 mm Luger cartridge. As originally designed, the Vis 35 has three distinct control levers on the left side. From front to back, a slide stop (which functions like that of an M1911 or High Power), a decocking lever on the slide and a disassembly lever on the very back of the frame.

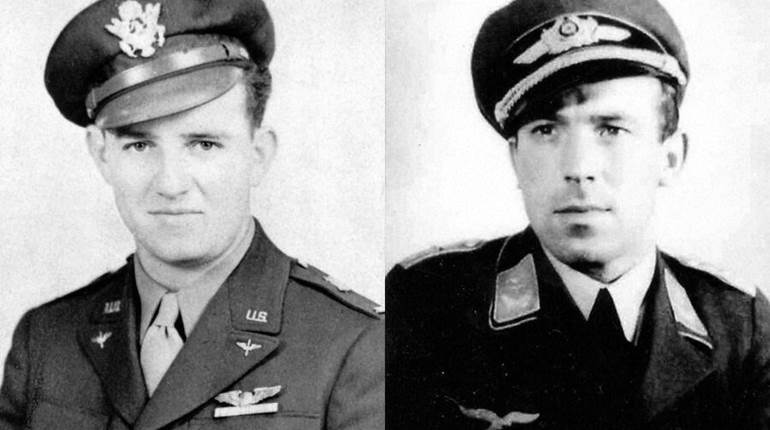

It was initially developed in Poland in 1935, with production beginning in late 1936 and continuing right up to the German invasion in 1939. About 45,000 pistols had been completed by that time, and they are identifiable by their Polish crests on the sides and top-quality machining. German forces occupied the Radom factory and decided to continue production of the pistols for German use. After reorganizing the factory and training workers, production restarted in late 1940.

In total, a remarkable 305,000 more pistols would be made under German control, with their finish quality steadily declining as the war progressed. The German guns have no Polish crest, and instead have Waffenamt inspection marks and the designation “P35(p)” on the left side of the slide. In late 1943 a significant visible change was made when the disassembly lever was removed from the design as a way to reduce production time and cost. This created the third main variant of the Vis 35 (prewar Polish, German three-lever and German two-lever). Lesser variations exist as well, including several styles of wood stock panels, Parkerized finish rather than blued, and others. By August 1944, the Red Army was approaching, and the factory tooling was loaded up and evacuated west into Czechoslovakia where production continued until March 1945.

The Vis 35 is highly regarded today, despite the poor fit and finish of the later German examples. Its inclusion of a decocking lever on a single-action pistol is a curious choice, insisted upon by the Polish cavalry board. While often compared to the M1911 with which it shares an external resemblance, it is actually a relative of the High Power, using the Browning’s solid unlocking system instead of the M1911’s swinging link. Its captive telescoping recoil spring and non-removable barrel bushing are also advances from the M1911, and shooters with large hands will appreciate its backstrap and hammer design which does not cause painful hammer bite.

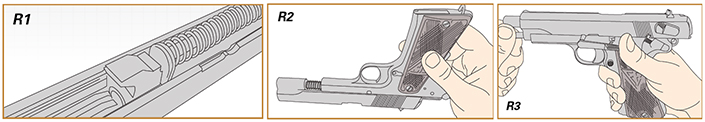

Disassembly

For two-lever pistols:

1. Lock slide open. Remove the magazine (19), confirm the chamber is empty, and then pull the slide (1) all the way back. Hold the decocking lever (36) down and slowly let the slide forward. The internal foot of the decocker will stop against the hammer (10) and hold the slide open. To release, simply pull the slide slightly rearward.

For three-lever pistols:

1. Lock slide open. Remove the magazine, confirm the chamber is empty, and then pull the slide back about 1". When the notch in the slide aligns with the disassembly lever, push the lever up to hold the slide in place.

For all pistols:

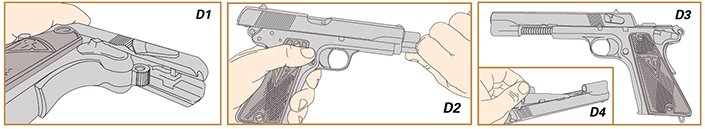

2. Remove the slide stop. With the slide locked open, hold the pistol with its left side facing directly downward. Grasp the exposed end of the recoil spring guide (34) under the muzzle and pull forward. The slide stop (27) will fall out.

3. Remove the slide assembly. While holding the slide against its spring tension, push the disassembly lever down (24) and out of engagement with the slide. Now pull the slide assembly forward and off the frame.

4. Remove the barrel and recoil spring assembly. Rotate the slotted recoil spring guide (30) 180 degrees, so the semicircular cutout is facing upwards. Pull the recoil spring (29) and assembly (30-34) out—the spring is captive, and will not fly out. Lift the barrel (35) up and out of the slide.

Reassembly

1. Reassemble slide components. Insert the barrel into the slide (this may require a bit of wiggling). Ensure the barrel is fully in place, with the locking lugs engaged in the top of the slide. Insert the recoil spring assembly into its recess in the front of the slide, with the semicircular cutout facing upward. Then rotate the spring guide 180 degrees so the semicircular cutout fits against the underside of the barrel.

2. Replace slide on frame. Replace the slide assembly onto the frame rails, the reverse of how it disassembled. This is most easily done with the pistol held upside down, as this will help keep the barrel fully engaged in its locking lugs. If the barrel drops out of those lugs, it will prevent the slide from moving into place properly.

3. Replace slide stop lever. Repeating your disassembly step to hold the slide open, set the slide stop lever loosely in its hole in the frame, facing directly upward. Pull the exposed end of the recoil spring guide forward and gently press the slide stop lever into place. You may need to guide it into place, but force is not required if the guide rod is pulled forward. Alternatively, the slide stop can be pushed directly into place without holding the guide rod, but this will require some force to push into place and one should be careful not to scratch the frame in the process.