The Luger is the direct descendent of Hugo Borchardt’s C-93 pistol, which was the first semi-automatic pistol to be commercially viable. Manufactured by Ludwig Lowe & Co. and its successor, Deutsche Waffen- und Munitionsfabriken (DWM), a total of 3,000 C-93s were made. However, the Borchardt was an awkward design, and DWM tasked one of its engineers, Georg Luger, with the job of improving it.

The pistol Luger created would become one of the most iconic handguns ever made, renowned for its accuracy and fine craftsmanship. It was used in both world wars by the German military, as well as being adopted by other nations. And, of course, the guns were very popular on the civilian market. The first military adoption was by Switzerland in 1900—it is quite remarkable how good the Luger was for being such an early design. These first guns were chambered for the 7.65 mm Luger cartridge, but Luger would soon also chamber it for the 9 mm Luger cartridge, which was developed for the pistol and has become commonplace today.

The Luger is unusual mechanically, using a short-recoil, toggle-link action to lock the breech. The toggle is made of three links that form a rigid flat bar when locked, thus containing the cartridge’s energy, which was significant for the time. Upon firing, the whole barrel and toggle assembly recoil rearward about a quarter-inch, pushing the toggle knobs into an inclined surface that breaks open the rigid toggle assembly, allowing it to bend like a knee joint to eject the empty case and load a new cartridge.

The development of the Luger involved surprisingly few real mechanical changes compared to other pistol designs. The two mechanical models are the original 1900 and the 1906 pattern, which featured a coil mainspring in place of the earlier flat mainspring, an improved extractor and flat textured toggle knobs. The other changes to the guns involved customer options, such as the presence or absence of a shoulder stock lug and grip safety, the barrel length and the direction of the manual safety’s movement. Magazine capacity was eight rounds, with the exception of the 32-round “snail drum” adopted in World War I for the German long-barreled artillery model. The Luger was eventually replaced as a military pistol, not because of any shortcomings as a handgun, but simply because of its high cost to manufacture.

NOTE: While one should always confirm that a firearm is unloaded before disassembly, this is particularly important with the Luger. If a cartridge is left in the chamber, it is possible for it to discharge with the upper assembly completely removed from the frame, because the whole firing mechanism is contained within the Luger’s upper assembly. These disassembly instructions apply to all models of Luger 1900 and 1906 patterns, military and commercial.

Disassembly

Remove the magazine, then pull the knobs on the toggle link (13) up and rearward to open the chamber and confirm that the pistol is completely unloaded.

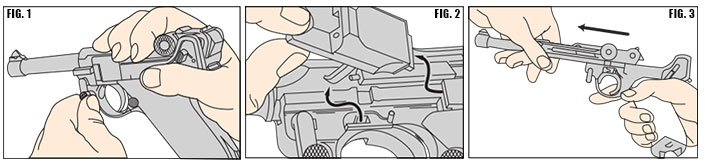

Press the barrel (2) rearward and, while holding it in that position, rotate the locking bolt (33), which is also the disassembly lever clockwise 90 degrees. (FIG. 1) The pressure on the barrel may now be released.

Press the barrel (2) rearward and, while holding it in that position, rotate the locking bolt (33), which is also the disassembly lever clockwise 90 degrees. (FIG. 1) The pressure on the barrel may now be released.

Holding the pistol left-side-up, lift the trigger sideplate (35) up and off the frame (25) (FIG. 2). Slide the barrel assembly off the front of the frame, ensuring that the mainspring guide’s rear hook (32) does not catch on anything (FIG. 3).

Press out the receiver axle (5) from right to left (it is flanged and will come out in only one direction) (FIG. 4), and slide the toggle assembly out the back of the receiver (sometimes called the barrel extension) (3). Note that the firing pin spring (23) will still put some tension on the toggle parts at this point.

Press out the receiver axle (5) from right to left (it is flanged and will come out in only one direction) (FIG. 4), and slide the toggle assembly out the back of the receiver (sometimes called the barrel extension) (3). Note that the firing pin spring (23) will still put some tension on the toggle parts at this point.

To remove the firing pin (22) and its spring, use a screwdriver to depress the spring guide (24) on the rear of the breechblock (17) slightly, and then rotate it 90 degrees counterclockwise (FIG. 5). It will come out under spring pressure, so be careful.

Reassembly

Replace the firing pin, firing pin spring and firing pin spring guide into the bolt, depress and rotate the assembly 90 degrees clockwise to lock it in place (exactly the reverse of the removal process).

Slide the toggle assembly into the receiver. Press the trigger bar (7) on the left side of the barrel extension inward to allow the toggle to move fully forward without tensioning the striker spring. Reinsert the receiver axle from left to right.

Slide the barrel assembly onto the frame from the front, ensuring that the mainspring hook at the rear remains upward to avoid catching it on anything (done most easily by having the pistol upside down for this step).

When the barrel assembly is about halfway onto the frame, ensure that the mainspring hook drops down into its recess in the frame.

Place the trigger sideplate in position on the frame, and then press the barrel assembly rearward against the mainspring pressure. While the barrel is being held rearward, press the front of the trigger sideplate down against the frame and rotate the disassembly lever counterclockwise 90 degrees.