Rock Island Armory can trace its roots to the early 1900s and a sporting goods store in the Philippines. A family business since 1941, it has survived war-time occupation, evolved into a major firearm and ammunition manufacturer, grown to supply an international market and expanded its operation with several facilities in the United States. The Rock Island Armory brand is just one arm of the larger Arms Corporation of the Philippines, or Armscor, but it is representative of the firm’s commitment to growth in the American market. Yet, despite likely producing more M1911s-America’s most-beloved pistol-than any other firm in the world, few Americans are familiar with the company or its story. It’s time all that changed.

From Foreign Shores

Looking back to 1905, Armscor began as Squires Bingham & Co. when the namesake pair of English expatriates opened a photo print shop in the heart of Manila. As the company expanded, so did its inventory of general trade goods. Developing a reputation for selling the best selection of sporting long guns and ammunition, the company took on the moniker, “Sportsmen’s Headquarters.” By the 1930s, Squires had been purchased by an American, Arthur Hileman; but, as clouds of war gathered over the Pacific, Hileman decided to liquidate his investment before the inevitable Japanese invasion of the Philippines. The company found a new owner in Celso Tuason. Martin Tuason, current president and CEO of Armscor describes his grandfather as a “born optimist,” and indeed he must have been. Sure enough, shortly after acquiring Squires Bingham, Tuason had his inventory of firearms and ammunition confiscated by the Japanese during their occupation of the islands during World War II. The company survived the war by trading in clothing and haberdashery.

In the years following the war, Squires Bingham & Co. worked to rebuild its business as the Philippines-and many other countries, for that matter-worked to rebuild its national economy. The country’s focus on industrialization was in line with Celso Tuason’s vision of expanding into the manufacture of his company’s most popular goods; namely, firearms and ammunition. Squires Bingham Mfg., Inc., was born, prospered and, in 1965, was handed on to Celso’s three sons, the second generation of Tuason leadership. In 1980, under the overall guidance of Demetrio “Bolo” Tuason, the firearm manufacturer was aptly renamed Arms Corporation of the Philippines, and within five years it had opened its first offices in the United States and acquired the Rock Island Armory brand, a name loosely resembling that of the Illinois military arsenal that began manufacturing Springfield Model 1903 rifles prior to World War I.

Since manufacturing began, Armscor has produced rifles, shotguns, semi-automatic pistols and revolvers. No products, however, have enjoyed more success than its .45-cal. M1911s. The post-war Philippines embraced the classic American sidearm, and the strong domestic demand fueled production and helped grow the business in the international arena. Today, Armscor products are available in around 60 countries, and through the years it has also produced guns for myriad other companies-STI Spartan, Auto-Ordnance and High Standard, to name a few-as well as American and international distributors to sell under their own brands. In this way, and somewhat unofficially, Armscor grew to become the largest producer of M1911 pistols in the world, and remains so today.

Philosophy, U.S. Production And Branding

Philosophy, U.S. Production And Branding

At a 2012 writers conference in Florida, Martin Tuason-current Armscor president and CEO, and the third generation to helm the company-gave a presentation that has stayed with me and served as the catalyst for this article. He described himself as a son of two countries, the Philippines and the United States. His relationship with the Philippines was based on his heritage and his roots. It’s where he and his family trace their beginnings and where the company his family built, and that his grandfather and father have passed down, was begun. There is no separating family and business for the Tuasons, each serves to support and grow the other. Likewise, there is no separating Armscor from the Philippines;the country is the home for the company, its base of operations, and the firm is a major employer and has been a contributing force in driving the nation’s industry since the end of World War II.

America, on the other hand, offers new opportunities for growth and prosperity. It may be cliché, but the American Dream still exists and, in hearing Tuason speak, it is clearly alive and well in him. He believes that expansion in the U.S. market is essential for the future of his family and business. A great admirer of the American workforce, he cited a strong work ethic, pride and attention to detail as hallmarks of his U.S. employees that are simply not as prevalent in other populations. He also expressed grave concern over political threats to our Second Amendment freedoms, freedoms that Tuason knows all too well are not guaranteed in other countries. He was adamant about defending those rights, and has already sacrificed his own time and treasure to do so. What could be more American than that? Tuason, and the whole Armscor family, embody patriotism for both countries, and each, I think, is better for having them.

At the conference, Tuason did not just talk about the past, he also explained his plans for the future. Armscor had, in 2011, opened its first production facility in the United States, an ammunition-manufacturing plant in Stevensville, Mont. This expansion, in addition to the U.S. headquarters facility in Pahrump, Nev., was the start of a larger plan to bring more manufacturing capacity to the United States and grow the company’s market share among firearm consumers.

True to the plan, and as of this article’s writing, Armscor has begun work on another U.S. manufacturing plant, this one also in Pahrump. The third state-side facility, it will be tasked with the production of Rock Island Armory firearms, as well as continued research and development in the firearm field. Once complete, the plant is expected to employ around 50 people and will likely increase the company’s production capacity and decrease product delivery times. It will also allow Rock Island Armory products to bear “Made In The U.S.A.” markings, certainly a landmark event for any company, and a sign of quality and credibility in the eyes of American consumers.

Speaking of brands and markings, it is important to delineate between the different families of products that fall under the Arms Corporation of the Philippines umbrella. First, Armscor remains the overall entity, both here and abroad, from which the sub-brands are derived. It is also the brand used for ammunition and firearms produced and sold in the Philippines. It is the original brand, only pre-dated by Squires Bingham, and very recognizable on the islands, so it makes sense to continue using it.

Armscor USA, by contrast, is a fairly new brand but with a clear link to the parent company. Armscor USA is used for all ammunition produced at the Stevensville plant, so, as the name implies, Armscor USA is U.S.-made ammunition. Finally, Rock Island Armory, the main subject of this article, is a name with American-roots that was acquired by Armscor in the mid-1980s. The brand has languished somewhat since its acquisition, but it now has a clearly defined role in Armscor’s operational and marketing programs. Rock Island Armory is the brand used for all firearms produced in the Philippines, but sold internationally, particularly in the United States. As well, firearms produced from the new Pahrump facility will also be sold under the Rock Island Armory brand. Simply stated, and with a focus solely on American consumers, Rock Island Armory makes guns, both in the Philippines and soon in the United States, and Armscor USA produces American-made ammunition.

Rock Island Armory’s M1911s

Rock Island Armory’s M1911s

In order to get a sense of Rock Island’s offerings, I chose to test the most basic model available as well as a higher-grade tactical-style gun; namely, the 1911 Standard G.I. in .45 ACP and the 1911 Tactical II in 10 mm Auto. My choices highlight one of the greatest features of the Rock Island Armory M1911 line, its diversity. With more than 20 models, in chamberings from .22 Long Rifle to .45 ACP, there is a gun for just about any purpose. Even better are the prices, with unadorned but well-made models selling well below $500, and even the most upgraded guns available in stores for less than $1,000. These are working-class guns, built to perform reliably but not break the bank. And while they may not have the features or 50-yd. accuracy of some semi-custom and full-custom M1911s on the market, they are solid, capable performers, as proven in our testing. That can be attributed to Rock Island Armory’s high production standards and its modern, accredited manufacturing facilities-Armscor has been ISO 9001-certified since 1997. Combining diverse selection with relatively low price points, Rock Island Armory offers a very accessible line of M1911s for first-time buyers and budget-conscious enthusiasts alike.

Both guns I evaluated were made from 4140 steel with cast frames and forged slides. Machining is through a combination of modern CNC techniques and more conventional processes, and finished components are Parkerized for durability. All barrels are machined from 4140 solid bar stock, then gun-drilled, reamed and button-rifled. Both the G.I. and Tactical II are 5"-barreled models.

The most apparent differences between the guns begin with the sights, the G.I. is topped with, you guessed it, G.I.-style, low-profile combat sights, while the Tactical II has an orange fiber-optic front and a fully adjustable rear sight. The G.I. model also has a traditional hammer spur, trigger and beavertail grip safety as compared to the elongated beavertail and skeletonized hammer and trigger of the Tactical II. Also obviously different are the stocks, the G.I. possessing non-descript, though not unattractive, smooth wood panels and the Tactical II wearing VZ Operator II G10 panels. The VZ stocks feature an appealing blue and black pattern consisting of waves and dimples, and the stocks are textured aggressively, which translated into sound purchase, even under the snappy recoil of 10 mm loads. A final distinction, at least externally, is the guns’ safeties. The G.I. utilizes the short, traditional-style, left-side-only thumb safety whereas the Tactical II’s is ambidextrous and the levers are both elongated for ease of operation.

Taking a closer look, the G.I. model stays pretty true in function and appearance to the original service arms. The slide has vertical serrations, as does the frame’s backstrap/mainspring housing. The frontstrap remains smooth. The slide interfaces with the barrel bushing, and the barrel’s contour is consistent with the original design. The recoil spring is contained by a standard-length guide rod and the recoil spring plug. Notable deviations are the enlarged and flared ejection port and the eight-round-capacity magazine, with its polymer baseplate. All in all it is a handsome, if basic, firearm with many of the characteristics found on its military-issue forebears.

Testing was conducted with off-hand familiarization fire and from a Ransom Rest with targets placed at 25 yds. Throughout the course of fire the gun proved handy, reliable and accurate. With two of the three evaluation loads it produced groups on par with much more expensive firearms. The Liberty ammunition grouped particularly tightly with three of the five, five-shot groups measuring under 2". The gun was a bit picky though, as groups fired with Winchester’s PDX1 were inconsistent, ranging from less than 2" to more than 6". Given the right ammunition, though, this gun represents an outstanding value, with examples commonly selling for just more than $400.

The Tactical II falls a bit farther from the traditional M1911 tree, featuring upgrades originally available only by aftermarket modifications, but now common in tactical- and competition-style production guns. Along with the aforementioned deviations, the Tactical II’s design improves purchase with a stippled backstrap/mainspring housing, as well as five vertical grooves machined into its frame’s frontstrap. The gun uses a full-length guide rod, a belled barrel-flaring near the muzzle-and no barrel bushing, lending a direct interface between the barrel and the slide when they are in battery. This configuration has been proven to be reliable and accurate, though it does require that a bent paperclip or similar tool be used to capture the compressed recoil spring during disassembly. A final feature that has its roots in action shooting sports is the flared magazine well. It is actually a separate component placed below the magazine well and attached to the frame via arms that hook around the stock panel screws and are secured once the stocks are tightened down. The unit facilitates quick reloading by providing a larger opening below the grip with angled sides to guide the eight-round magazine into the well.

Testing the Tactical II proved a bit more challenging than that for the G.I. model, mostly due to its chambering. The 10 mm cartridge produces a very snappy recoil impulse when fired, and even the heft of the full-size, all-steel gun did little to diminish it. Problems began when the gun was secured in the Ransom Rest and the first shot produced enough recoil to rebound the gun back into the rest’s trigger bar, inadvertently firing a second shot. Needless to say a ceasefire was immediately called, the gun cleared and staff began diagnosing the problem. With some tweaks to the testing apparatus, the problem could have been surmounted; however, the magazine’s production schedule called for a more expedient solution, which came in the form of Crimson Trace Lasergrips. Experience has shown that using the laser sight often produces better 25-yd. accuracy than pistol iron sights alone because of the relatively short sight-radius afforded by handguns. Testing proceeded, though the snappy recoil continued to cause group sizes slightly larger than they might have been in a mechanical rest-low-left shots are a tell-tale sign of impulse anticipation in right-handed shooters and were present in several groups fired for evaluation. As well, the somewhat heavy trigger did not help the cause. Still, accuracy was good, as shown in the accompanying table, but I believe the Tactical II is capable of even better results.

In the firearm industry, quality, accuracy and value are key considerations in product development, and the mastery of each can pay dividends many times over. Rock Island Armory produces a comprehensive line of M1911 pistols that display the two former characteristics while maintaining the latter, in spades. Not only that, the company has a heritage of entrepreneurial spirit, patriotism and family bonds which have combined and, over time, turned what was once a foreign businessman’s American dream into a present-day reality.

Rock Island Armory 1911 Standard G.I.

Importer: Rock Island Armory, 150 N. Smart Way, Pahrump, NV 89060; (775) 537-1444

Action Type: semi-automatic, recoil-operated center-fire pistol

Caliber: .45 ACP

Slide: Parkerized forged steel

Sights: fixed combat-style

Frame: Parkerized cast steel

Trigger: single-action, 4-lb., 7-oz. pull

Magazine: detachable box; eight-round capacity

Barrel Length: 5"

Rifling: six-groove, 1:16" RH

Overall Length: 8¾"

Width: 1¼"

Height: 5½"

Weight: 39 ozs.

Accessories: hard case, owner’s manual

Suggested Retail Price: $550

Rock Island Armory 1911 Tacticall II

Importer: Rock Island Armory, 150 N. Smart Way, Pahrump, NV 89060; (775) 537-1444

Action Type: semi-automatic, recoil-operated center-fire pistol

Caliber: 10 mm Auto

Slide: Parkerized forged steel

Sights: orange fiber-optic front, fully-adjustable rear

Frame: Parkerized cast steel

Trigger: single-action, 6-lb., 6-oz. pull

Magazine: detachable box; eight-round capacity

Barrel Length: 5"

Rifling: six-groove, 1:16" RH

Overall Length: 89⁄16"

Width: 1¼"

Height: 5¾"

Weight: 43 ozs.

Accessories: hard case, owner’s manual

Suggested Retail Price: $737

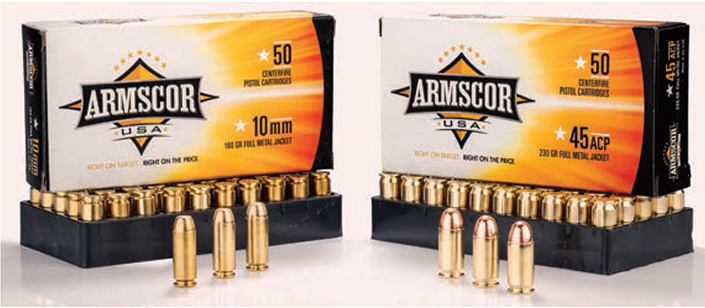

Armscor USA Ammunition

Armscor has long been in the ammunition business, but it was not prevalent on the U.S. market or domestically produced until the 2011 opening of Armscor USA’s Stevensville, Mont., plant. Being sound business folks, Armscor USA focused production on calibers and cartridges that correspond to Rock Island Armory’s firearm offerings. Luckily for consumers, the selection is diverse and spans the rimfire, center-fire pistol and center-fire rifle categories. In the realm of rimfires, Armscor USA produces three types of .22 Long Rifl e ammunition based on velocity—standard, subsonic and high—as well as a .22 WMR cartridge. For center-fire pistol ammunition, the company offers training-style loads in .22 TCM—a proprietary bottleneck center-fire cartridge capable of velocities greater than 2000 f.p.s. from a 5" barrel—9 mm Luger, .357 Mag., .38 Spl., .380 ACP, .38 Super, 10 mm Auto, .40 S&W and .45 ACP. Rounding out the line are center-fire rifle cartridges in .223 Rem. and .30 Carbine. If the U.S. economy existed within a vacuum, all of the aforementioned loads would be in full production and readily available at every local distributor. Unfortunately, Armscor USA, like all ammunition manufacturers, has had to prioritize production in order to meet the challenges brought on by the lingering nationwide ammunition shortage. What this means for consumers is that ammunition availability could be hit-or-miss. Armscor USA invested heavily in new equipment last year, in order to increase production and meet demand. Even so, specific loads in certain regions could be hard to find. For this article, I was able to test extensively the Armscor USA 180-gr. 10 mm Auto and the 230-gr. .45 ACP—both full metal jacket loads. Data is published on p. 78 and 80, but in summary, both exceeded expectations, producing good accuracy for standard training cartridges, and achieving velocities that were consistent with similar products.