A few months back, when Steiner Optics extended to American Rifleman the invitation for a writer to travel to its plant for the purpose of not just witnessing its riflescope production in person but actually constructing a T5Xi with his own two hands, I jumped at the opportunity. Prior to this adventure, if I’m being honest, I had never been much of a scope guy. I’ve always appreciated the precise interplay between many small parts necessary for a firearm to function properly, yet I’d never really extended that same curiosity to optics. I’ve always just treated them as an afterthought, with little regard to their inner workings or the meticulous care that goes into making them well.

Many times I had heard the common axiom within gun circles that “You should spend as much money on your scope as you did on your gun,” and had always found it to be patently absurd. Oh, I expected my optics to be utterly reliable—I just had no appreciation for why that reliability needed to cost so much. But having the opportunity to see how things are done behind the scenes often grants us a better appreciation for all that goes into a finished product, and I was hopeful that a visit to Steiner to build my own T5Xi would have the same impact regarding my attitude toward scopes.

Conventional wisdom states that, for about the past 150 years, the world’s best optics have come from Germany. While there are many exceptions, there’s also plenty of evidence to help back-up that assertion. But in recent times more and more high-end Teutonic optics companies are realizing that there are savings to be had by outsourcing their production to skilled laborers in the United States, resulting in German-engineered products at more affordable price points. Steiner is one such manufacturer; although headquartered in Bayreuth, Germany, the company assembles its GS3 and T5Xi riflescope lines from its stateside factory in Greeley, Colo.

Arriving in Colorado, I found that I was one of four industry writers invited on this trip. In order to avoid our presence having a negative impact on the plant’s production schedule, our scope-building event was held on Sunday morning, with the Steiner staff present having all volunteered to come in on their day off just to help guide our very willing, but very novice, hands through the process—it was my first indication of the level of dedication these workers have for their craft.

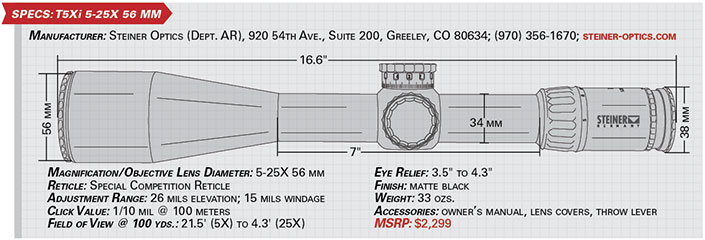

The T5Xi is one of Steiner’s tactical riflescope lines, intended for law enforcement use and precision competition shooting. Introduced at SHOT Show 2015, it comes in three models—a 1-5X 24 mm, a 3-15X 50 mm and a 5-25X 56 mm—all sharing 5:1 magnification ratios and illuminated reticles (hence the model designation). Discussing my upcoming trip with numerous co-workers, in their collective decades of writing for the gun industry none of them had ever heard of a scope-building media event, however, the general consensus was that the hands-on portion of the event would surely be minimal—boy, we could not have been more off. There are approximately 160 parts to the 5-25X 56 mm version of the T5Xi (the variant selected by Steiner for the event), and I was personally responsible for assembling about 140 of them.

Steiner ships in finished, fully multi-coated lenses for the T5Xi from Germany, but the rest of the riflescope is built in Greeley. As you can imagine, debris and airborne particles are the natural enemy of a scope’s internals, so Steiner’s assembly room operates under cleanroom protocols and is kept as sterile as possible through the use of hair nets, work smocks and shoe booties.

The first step in the creation of the scope was construction of the erector tube, which Steiner calls the guide tube. The numerous lenses within this vital internal subassembly not only allow the scope’s magnification to be adjusted and the image to be properly erected—delivered to the user’s eye right-side-up—but it is also by way of two screws pressing against the erector tube that the firearm’s point of impact can be adjusted by the shooter. In addition, it is onto a lens forward of the erector optics that the T5Xi’s reticle is etched; its placement there, in the first focal plane, allows the reticle’s subtensions to remain constant throughout the scope’s entire magnification range.

Steiner’s 5-25X 56 mm T5Xi utilizes what the company calls its Special Competition Reticle (SCR), a mil-based design that features 1/5-mil windage and 1/2-mil holdover lines. The SCR also has 1/10-mil ranging brackets along both sides of the horizontal stadia line and at the top of the reticle on the vertical stadia to allow the user to manually reckon the distance to his or her target. As mentioned above, the T5Xi’s reticle is illuminated, and a turret on the left side of the unit houses both the illumination- and parallax-adjustment knobs. Powered by one CR2450 battery, the system has 11 brightness settings, with an “off” position situated between each “on” setting. When activated, the top six mils of elevation marks and three mils of windage marks in each direction glow red—an essential feature for shooting in low-light circumstances or against a dark backdrop.

It was mere seconds into the first step of scope manufacturing that I caught my first taste of what would be a day-long education in just how much expertise goes into every Steiner, as it immediately became apparent that the company’s assembly crew strives for, and accepts, nothing less than perfection. For a Steiner consumer, this is phenomenal news; for a neophyte assembler attempting to earn the approval of the unfortunate company employee tasked with showing me the ropes, it could be really frustrating.

There are numerous glass lenses incorporated into the guide tube assembly, and they must be rendered spotless on both sides before they can be glued into place within it. Cleaning a large glass pane to passable clarity is easy; cleaning a lens no larger than a dime to literal flawlessness, armed only with an acetone-dipped cotton swab, is maddeningly difficult. Now repeat the process a few dozen times. More often than not, my efforts to remove one tiny smudge on the lens succeeded only in leaving two or three giant smears in its wake. After watching me struggle through the operation several times, my factory assistant would step in and, with a practiced hand, deftly wipe it spotless in one pass, demonstrating technique honed through countless hours of diligent repetition.

This would be a theme repeated consistently throughout the day. The individual steps of scope assembly are not difficult, per se, but to do this detail-oriented work properly requires highly knowledgeable and skilled workers with steady hands who, through practice, know the operations by heart and have the patience to do it hour after hour, day after day. Watching the Steiner crew speed through a precise operation that would take me at least 10 times as long to complete was both humbling and awe inspiring. To say that I left with a powerful admiration for the company’s T5Xi assembly staff would be a great understatement.

Once all components of the erector tube assembly were properly installed, including the LED that powers the illuminated reticle, it was time to video-collimate that part, wherein a piece of specialized equipment was used to ensure proper alignment between the optical axis of the lenses and the mechanical axis of the instrument. This was a very precise but straightforward process requiring delicate fine motor skills and plenty of persistence. Upon completion of this step, next came the time to build the turret assembly and the springport, and, along with the finished erector tube, install them all within the T5Xi’s colossal one-piece, 34-mm body tube.

Windage adjustments are made to the 3-15X 50 mm and 5-25X 56 mm variants of the T5Xi via a low-profile turret on the right side of the scopes, while elevation adjustments are made using a top-mounted turret unique to these two models featuring what Steiner calls its Second Rotation Indicator (SRI). It is an ingenious design that prevents the shooter from getting lost on his dial. After the first revolution of the turret (equaling 12 mils of elevation adjustment), the values displayed in the turret’s indicator windows automatically shift to reflect the actual amount of adjustment being applied—no guesswork or math equations required. The turrets have a click value of 1/10 of a mil at 100 meters. Given that the 1-5X 24 mm T5Xi will primarily be used at closer ranges with no need to dial for dope, that model instead ships with capped turrets and a different reticle calibrated for either the 5.56 mm or 7.62 mm NATO cartridges.

The 5-25X 56 mm T5Xi is built like a tank, measuring 16.6" long and weighing 33 ozs. A quick survey of riflescopes on the market today featuring similar magnification ranges revealed the T5Xi to be very near the top of the heap in terms of both of these measurements—and Steiner has done well to ensure that all that heft translates into an extremely rugged product. Perhaps the thing about my time at the Steiner plant that stands out most vividly in my mind, even months after returning home, is just how harshly the company handles each T5Xi it produces before the scope is allowed to leave the factory.

At every step along the assembly line the optic is repeatedly pounded sternly on the countertop. This practice ensures that its components are well-seated and knocks loose any debris that might have found its way inside—in which case the part is disassembled and re-cleaned, and the process begins again. This occurs perhaps a half-dozen times throughout the scope-building process, and it really points toward the company’s dedication to offering an unfailing product and the confidence Steiner has in its scopes. Further emphasizing this confidence, the T5Xi comes with the company’s Heritage Warranty, which states that the manufacturer will fix or replace any faulty scope at no cost for the life of the product, not just the initial owner.

With the tube’s internal hardware all in place and the turrets installed, we next cleaned and mounted the T5Xi’s 56-mm objective lens. Once completed, we again went through the collimation process, this time to check for correct orientation of the objective with the rest of the internal components. Happy with the alignment of our scopes thus far, we then proceeded with assembly of the eyepiece.

The eyepiece on the 5-25X 56 mm T5Xi features a 38-mm ocular lens and a locking diopter that prevents accidental rotation of the diopter once the optimal setting has been found. The figures on the aluminum magnification ring face to the rear, allowing the shooter to check and adjust his or her magnification setting without coming off the rifle. An easily installable throw lever also comes with the unit, providing a little added leverage for making rapid magnification changes.

The eyepiece now in place, the T5Xi was finally all together. All that remained was a brutal pre-inspection recoil test and to nitrogen-purge the optic. Regarding the former, the company holds different scopes to different standards, but each 5-25X model that comes off the line is loaded into a recoil machine that forcefully strikes the T5Xi on its nose 275 times. According to Steiner, the exact amount of recoil energy the test is attempting to replicate is a proprietary secret, but in ballpark figures, it roughly simulates the recoil of a .338 Lapua Magnum cartridge.

This is not just a spot check for a few unfortunate specimens; every single T-Series scope is put through a recoil test—ensuring that, before its operational life has even begun, each unit has already withstood more abuse than the average end user will put it through in decades of normal use. I can tell you from personal experience that it was painful watching something that I had just poured several hours into being handled with such seeming disregard, but my concerns were unfounded; the scope I had built shrugged off the recoil test without issue.

Finally, our scopes were connected to a tank and filled with nitrogen. This inert gas displaces all oxygen and moisture trapped inside and, because it is unaffected by changes in temperature, will prevent the lenses from fogging when the scope travels from a warm environment to a cold one. The generous utilization of O-rings in the construction of the T5Xi (16 if I remember correctly) ensures that the model is waterproof to depths of 33 ft.; a 10-minute submersion test confirmed that my particular scope was leak-free.

Upon completion of the water test I proudly presented my completed T5Xi to one of the company’s two quality assurance technicians, and he proceeded to rip it to shreds, using a black marker to point out all the minute imperfections that would have caused him to kick it back to the assembly workers had it been built by them. Of course, at this point it came as no surprise that a company as fastidious as Steiner would employ the two biggest perfectionists of all as the final gatekeepers before its product is allowed to reach the market.

However, rather than make me undo and redo the final several steps of the process in order to rectify the deficiencies in my scope, Steiner was gracious enough to let us call it a day. I arrived the next morning to find that the elves had been busy while I was sleeping; the small speck of debris that I had somehow allowed to get trapped along the periphery of one of my scope’s internal lenses had magically disappeared overnight, along with every other minor blemish caused by my clumsy, inartful hands. It was now a Steiner worthy of the name.

I spent the next two days putting the new T5Xi to the test out in the field. First, the scope was mounted atop a Sako TRG 22 using Steiner’s T-Series aluminum rings. Once zeroed in, the writers used the .308 Win.-chambered rifles in a friendly, timed, four-stage competition that was designed to test the capabilities of the T5Xi. The first stage required the shooters to use the SCR’s ranging brackets to engage a target set at an unknown distance. Each of the remaining stages involved different scenarios of firing on multiple targets at various known distances, requiring us to memorize our dope and make multiple elevation adjustments on the fly. The ammunition used was Hornady’s 168-gr. Match load, and target distances ranged from 225 yds. to 1,100 yds. Even out beyond a half-mile, the Steiner-equipped TRG 22 was able to connect with its target consistently.

Next, we mounted our scopes onto .223 Rem.-chambered Tikka T3x Varmint rifles and headed to the nearby Longmeadow Game Resort in Wiggins, Colo., for a morning of prairie dog hunting. For the sake of speed I mostly used holds for both windage and elevation rather than take the time to make turret adjustments. The combination of rifle and glass was certainly up to the task, as we made short work of cleaning up a dog town, and I personally was able to connect with the tiny vermin all the way out to 480 yds. Steiner advertises the T5Xi as having an eye relief range between 3.5" and 4.3", and during neither excursion did I experience much difficulty keeping my head properly positioned within the eye box—even at high magnification. Colorado’s rapidly changing summer weather patterns afforded the opportunity to test the scope in both sunny and thickly overcast environments, and throughout my in-the-field testing I found the T5Xi’s image sharpness, light transmission and color fidelity to be excellent—regardless of the ambient lighting conditions.

For a precision scope of this nature, the shooter needs to know that each click of the turret moves the point of impact exactly the correct amount, every time, and while all my shooting in Colorado seemed to indicate that the T5Xi’s adjustments were precise and repeatable, I still wanted to conduct a little more testing at my home range. Upon returning to Virginia with the scope, I mounted it atop my Ruger Precision Rifle chambered in 6.5 mm Creedmoor and headed to the range to shoot the square. After establishing zero, the square was then shot at 100 yds. with 3 mils of adjustment (30 clicks) made between each corner. The end result, four five-shot groups with group centers an average of 10.875" apart, measuring an average of 0.68" wide, confirmed what I had already experienced firsthand—that the scope’s adjustments are trustworthy.

Steiner optics are expensive; the 5-25X 56 mm T5Xi retails for $2,299, which amounts to a considerable investment for all but the most affluent of shooters. However, after getting the chance to successfully birth a finished specimen from a large pile of parts—and to suffer through the labor pains of that delivery—I left the Greeley plant convinced that they are also a value. The experience of building one was humbling and far more mentally exhausting than I ever would have guessed, but the endeavor was ultimately illuminating, as it not only demonstrated the quality of the components involved, but also made real for me just how much skilled technique is required.