For my money, handloading has got to be the most interesting topic in the industry, right down to the mindset of those who seek training for it. When I teach a firearm-handling course, I have to work strenuously to keep my student’s attention during the safety portion, whereas those looking to produce their own rounds usually want to hear about nothing but safety. To their surprise, keeping things safe is not as complicated as it first appears, especially with a little preliminary knowledge. These folks have the advantage of learning from a certified instructor; I, for one, was not so fortunate. Suburban Long Island, N.Y., didn’t have the training avenues that it has today, and believe it or not, there was a time before YouTube, so all I had was a Lyman 48th Edition Reloading Handbook to show me the way. Nonetheless, I got there and learned a few ways to stay safe as I developed my routine. Here are five safety tips that I share with my students:

Select Powders That Can’t Double-Charge

The only thing potentially more catastrophic than putting the wrong powder into a case is to put twice the amount. Once your tooling is set, overcharges either don’t happen or they happen at a rate of x2. If a case can’t hold two charges of the powder being used, we have a handy alarm that shows us when this phenomenon has taken place.

This is where the handloader has a touch of control. By choosing powders that nearly fill the case before hitting the published maximum charge, one is afforded this protection. Propellants like Trail Boss are excellent for taking up the extra space of cartridges that were originally loaded with black powder, and extruded rod types excel in most modern bottleneck rounds. However, be sure to keep to safe, published data and never work outside the book to make this happen.

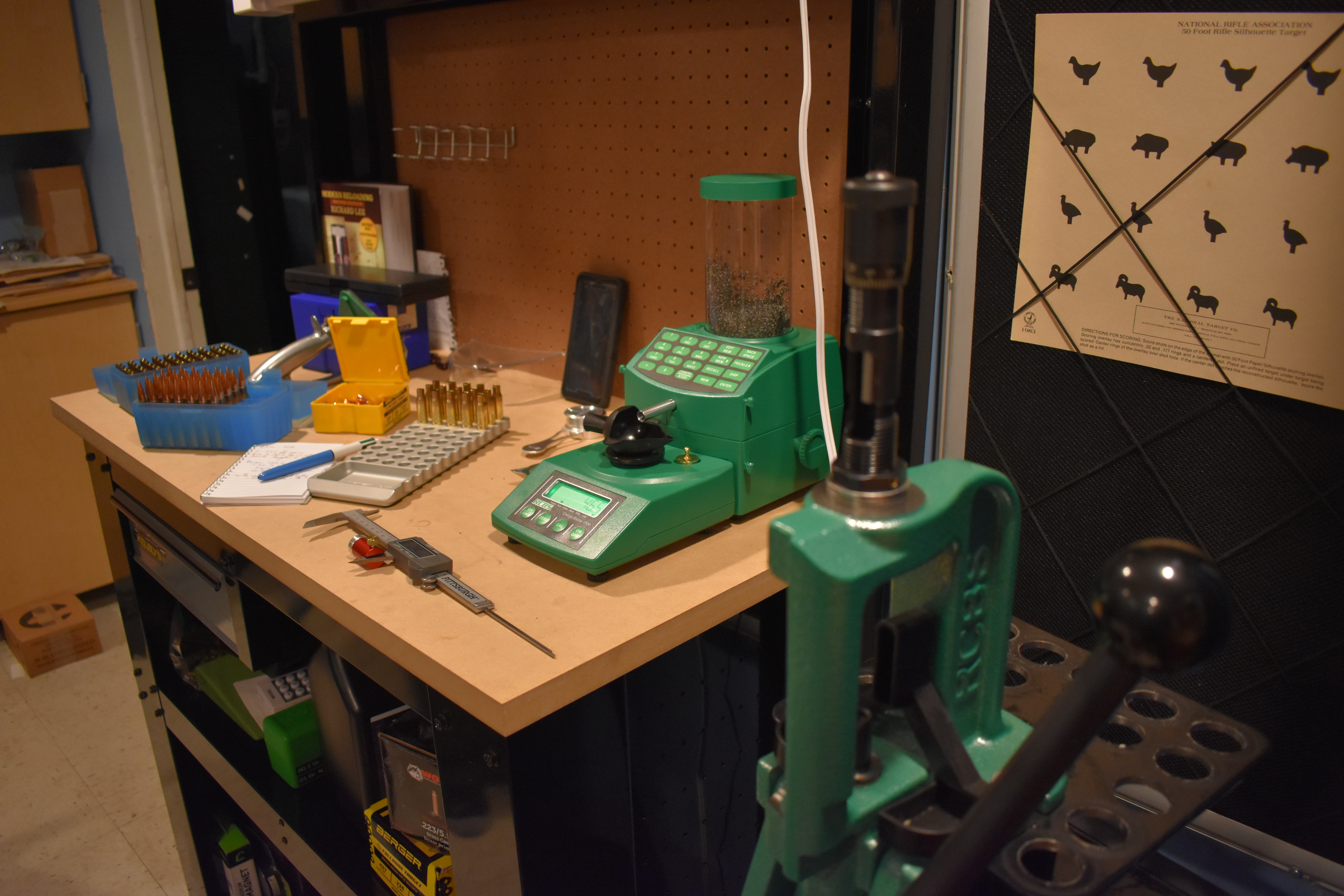

4. Clear Progressive Jams In The “Up” Position

Multi-stage progressive machines are excellent for pumping out high volumes of handmade ammunition. However, with complexity comes a certain failure rate. When something goes wrong on a progressive, we must halt, figure out the problem, remedy the stoppage and then pick up precisely where we left off. If we fudge the step we are on, in some cases, we might get two powder charges or none at all. Lesser issues like skipping a crimp or a sizing abnormality are also possible and will show themselves at the range or during a hunt.

To keep track, I have found that it helps to keep the ram as close to the up position as possible, particularly if the press indexes on the down stroke. This allows you to pull the problematic case from the line and continue on with the others relatively unaffected. Visually and physically inspect each remaining case to ensure that the problem wasn’t two-fold, and you should be right back in business. Of course, this advice assumes the issue happened when the cases were running up into the dies, as this is the most common scenario. However, if you have some sort of issue on the down stroke, it’s best to go as low as you can before removing the offending shell.

3. Label Primers

Just like powder, primer packages are also clearly labeled before being shipped. Well, for the most part, anyway. Most manufacturers have gone out of their way to incorporate a number system along with the primer type right on the outer layer of the packaging; however, that all goes out the window once you slide them out of that cardboard sleeve.

Standard primers and their magnum counterparts look identical in many cases, and switching one for the other could cause a dangerous over-pressure scenario. Something that I like to do anytime I take a brick of primers in is to use a fine-tip felt pen to put some of the information on the edge of the plastic primer divider. This helps me in case the two become separated beyond recall for some reason.

2. Only Charged Cases Stay Up

Maybe not so much dangerous as they are inconvenient; squib loads can easily ruin your day. For the handloader, this is typically rooted in forgetting a powder charge. Should that bullet fail to leave the barrel, one must pound it out and have the gun inspected before further use (under no circumstances should one try to shoot it out).

A simple system that I employ is keeping cases either on their side in a bowl or mouth down in a loading block until they are charged with powder. With strict adherence to this self-imposed rule, it becomes next-to-impossible to miss a charge. I typically dispense powder and then immediately seat a bullet, which also goes a long way to stave this off.

1. Label Powder Hoppers And Dispensers

Gunpowder arrives from the manufacturer in a clearly marked container, making it relatively hard to pull the wrong one off the shelf. This remains true until we pour it into a powder dispenser or meter. Sure, you can keep the bottle right next to your device, but it’s easy enough to get cluttered and let these bottles pile up on your reloading bench (something else that needs to be avoided). A simple note with the brand and type of powder being dispensed can avoid putting the wrong stuff into the wrong ammo or contaminating a jug with the incorrect propellant.

Safe, accurate and effective loads are typically the byproduct of carefully produced ammunition. As I write these words, I remember the 'sage' advice of a gentleman behind the gun counter who told a customer that “he can fill a .30-'06 case all way with any powder and be fine.” Lord only knows how many people he’s affected with that “advice.” On the other end of the playground are the shooters who weigh bullets to ensure nothing silly got mixed in; these are the guys who also seem to keep winning the matches. A combination of good housekeeping, attention to detail and common sense are about all it takes to get the results you seek without injuring yourself or others. Take your time, use good load data and make the process as much your own as the ammunition it yields.

![Auto[47]](/media/121jogez/auto-47.jpg?anchor=center&mode=crop&width=770&height=430&rnd=134090788010670000&quality=60)

![Auto[47]](/media/121jogez/auto-47.jpg?anchor=center&mode=crop&width=150&height=150&rnd=134090788010670000&quality=60)