M1 Garands have been used for casual and competitive target shooting ever since they came home on the shoulders of GIs in the 1940s. At this time, ammunition wasn’t quite what it was today, with a large bit of it being nothing more than repackaged surplus.

In those days, reloading was also in its infancy, and components were typically pull-down bullets and powder. Sadly, when you talk to some folks who reload for this old warhorse, they still opt for those same bulk bullets and surplus powder today! For this reason, the M1 often gets a rap as being inaccurate, and this has always bothered me.

Looking down at my post-Korean War M1, I decided it was time to see exactly how much accuracy I could squeeze out of it and set out on yet another handloading adventure. This M1 Garand is no stranger to the range. In fact, it has seen rigorous service at Renaissance Firearms Instruction in our Historic Military Firearms Shoot. By extensive, I mean far more than 5,000 rounds have been through it.

However, through good maintenance, cleaning and cooling procedures, it still gauges just shy of “3” at the muzzle with a throat erosion slightly below a “5”. Mechanically speaking, this would categorize it as a CMP “Service Grade." However, I describe the stock as “a Tung oil experiment gone horribly wrong."

Other than that, the gas cylinder is still nice and tight, ensuring that the front sight doesn’t have any wiggle, and the clicks on the knobs are still as sharp as they were in 1956. Overall, it was certainly worthy of the reloading project.

The advancements in reloading tools in just the last 10 years alone have been breathtaking. If you would have told me that my cell phone would be involved in dumping powder charges, I would have never believed it. Sure enough, several powder dispensers on the market now have Bluetooth connectivity to help streamline the process.

The newest of these is the RCBS MatchMaster with its .04 +/- grain accuracy. At the time of this writing, it is the most precise scale that RCBS makes. In addition to the company's new scale, I opted for its new dies that also carry the MatchMaster moniker.

These dies come in several varieties, depending on your application, so we went with the full-length set that utilizes your choice of neck sizing bushing to adjust the bullet tension to perfection.

Loading for semi-automatic rifles is always a delicate dance, as you want your bullet in tight enough that it stays put during cycling and recoil but you want an effortless release for best accuracy. The set also included the MatchMaster seater die that allowed me to drop bullets into a side window, saving my fingers from the typical pinching.

These dies also feature a precision micrometer seating stem, which allowed me to achieve a consistent 3.325” overall length without any fussing around. Other than that, we didn't venture too far outside typical reloading gear.

The components that were available to use also depicted decades of product development. All good rounds start with consistent brass. While best known for its pistol brass, Starline had shifted its focus to bottleneck cartridges and nailed it. The 30-06 Springfield brass is among the company's newest offerings, and we found it far more consistent right out of the bag than we could ever hope for with military surplus brass.

As we weighed a sample of 20 cases, we recorded no more than a 1.1-grain extreme spread with our lightest case weighing 187.8 and our heaviest only 188.9. I literally cannot prep HXP surplus brass to this level of consistency. Necks were also right on the money, as we measured a perfect .014” thickness all around on nearly every case in that sample. All that was required was a quick run through the sizing die and a light chamfer and deburr of the case mouths.

We primed these cases with CCI BR2 benchrest primers, because I have always found these to be the most consistent and reliable in anything that I have ever loaded. Many might say that the M1 "won't notice them." However, I believe every firearm deserves all the help it can get.

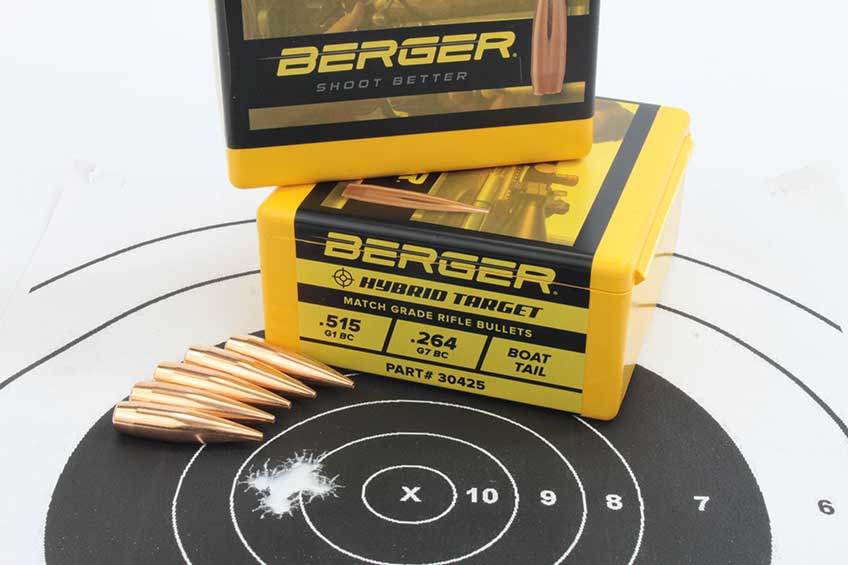

For bullets, we decided to give the new Berger Hybrid Target 168-gr. pills a whirl. The hybrid secant/tangent ogive on these boat-tailed beauties makes them less dependent on their positional relationship with the barrel's lands. This is important for semi-automatic firearms, as their magazines greatly limit how close you can get.

For powder, I decided to branch out and give VihtaVuori N150 a try. This powder has a few technological advances over the classic go-to: H4895. These include a de-coppering agent as well as temperature stability. Its short grain flowed very easily through the MatchMaster dispenser and resulted in nearly zero overthrows. Mind you, that an overthrow with this dispenser is only 0.02 of a grain-or essentially 2 kernels of powder.

We loaded from 41.00 to 47.50 in .50 grain increments and arranged our 14 different test loads into two MTM Deluxe H-50 boxes. Anyone who doesn’t see the value in a properly-fitted, locking ammo box has never spilled a round of load development on the floor only to have to pull 50 bullets and do it all again.

My range day was a dream come true for load development. We were blessed with 60-degree weather and only a five MPH wind, and at my back at that. Whenever I am forced to do load development with iron sights, I limit my distance to 50 yards. This allows me to create a more repeatable sight picture, reducing the possibility of this type of shooter error. I cradled my Garand in a Caldwell Rock BR Competition front shooting rest and supported the rear with a Champion Wedge bag.

After confirming my zero, I fired groups with each powder charge. Not to my surprise, I hit a node right off the bat with a group that was just outside of MOA. Take note that this is not the first time that I have experienced this. If safety alone isn't enough reason to start at the bottom and work up, let accuracy tip the scale.

Of course, it wouldn't make sense to leave the other 13 loads in the box, so I proceeded as originally planned. As charge weight and ambient temperature increased, so did barrel temp. I used a MagnetoSpeed Rifle Kuhl to help reduce the wait time between groups while I policed up my brass, expediting my range session quite a bit.

About halfway through, I hit my second node at around 45.0 grains. My best group was .62" (1.24 MOA) at 45.00 grains. At 45.50 grains, the first four shots measured .75" (1.50 MOA) and a fifth opened it up to 1.75", still respectable for an M1.

When it comes to selecting a load to mass-produce, I like to consider the final application, as well as my projected means of loading it. That being said, I decided to stay away from the 41.00 loading, even though it produced terrific accuracy and mild recoil.

Although it was a great shooter, the node was really narrow, meaning that just a bit over or under, and I would not have the same accuracy. It also is going to be on the slower side of the velocity scale, and I plan on reaching out to at least 800 yards with it.

For these reasons, I selected 45.20 grains as my final test load. This load can be a few tenths either way and still produce exceptional results. This opens the possibility of metering charges and maybe even complete production on a progressive press.

However I decide to fill cases and seat bullets, one thing is for sure: the Garand can be an exceptional shooter if you give it everything it needs to succeed.