Cocoa, Fla.-based Kel-Tec CNC Industries, Inc., forever changed the accepted idea of defensive shotguns with the debut of its highly distinctive, dual-magazine, pump-action, 12-ga. KSG. Its successful launch lent credence to expanding the line, which the company promptly did with the KSG-NR, KSG Tactical and KSG-25, the latter of which is reviewed here.

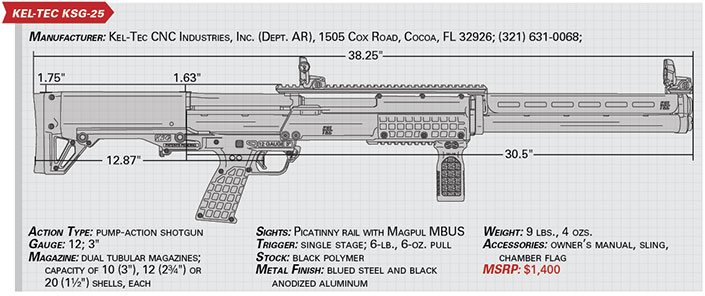

Like most line extensions, the core characteristics of the KSG-25 stem from the original design. Somewhat unusual in the shotgun world, the KSG-25’s bullpup configuration results in a shorter overall length, even with an almost unheard of 30.5" barrel. Despite that, the KSG-25’s overall length is 38.25", which is slightly shorter than most defensive shotguns.

Safe for use with lead and steel shot, the fixed cylinder-choke barrel must be 30.5" in length to enable the dual magazines tubes—located side by side beneath the barrel—to accommodate 12, 2 3/4" shells each. Combined with a round in the chamber, that’s 25 (hence the model designation) 12-ga. shells with which to resolve a problem. Alternatively, each tube can hold 10, 3" or 20, 1½" shells for all-up totals of 21 or 41, respectively. The Henry axiom, “... load on Sunday and shoot all week,” seems especially applicable.

Loading the tubular magazines requires that the slide be forward. Additionally, the three-position magazine selector switch, located forward of the ejection port, must be moved to the same side as the magazine that you want to load (i.e., left for the left magazine). In doing so, the other magazine is blocked. This action permits the magazines to be filled with differing loads, such as buckshot and slugs, with the shooter switching between them as necessary.

Pressing downward on the bilateral action-bar lock, which is situated in front of the trigger guard, frees the slide (fore-end assembly) to travel rearward, thereby lowering the carrier (ejecting downward a hull if one had just been fired) to accept an awaiting shell. Pushing forward on the slide chambers the round. Mounted to dual action bars, the slide is, unsurprisingly, made from polymer, and beneath it there’s an integral, 6" MIL-STD-1913 Picatinny rail to which a Magpul Rail Vertical Grip (RVG) is affixed. It can be removed, but the RVG aids in cycling the action forcefully for proper functioning.

Beyond the fire controls already described, the KSG-25 has a crossbolt-style safety and single-stage trigger housed in the polymer lower unit. Unlike most shotguns, the square-shaped safety travels from left to right to move from safe to fire. For right-hand shooters accustomed to using the trigger finger to disengage a crossbolt safety, it’ll take time to adjust to using the thumb. Left-hand shooters will need to use the trigger finger. Moving the button results in an audible “click” that resonates through the gun.

Consistent with the heavy triggers and long linkages typical of bullpups, the KSG-25’s trigger pull measured 6 lbs., 6 ozs.; however, it’s still lighter than the pull weight of many shotguns. Additionally, there’s considerable travel, though the reset is short. Reaching the polymer trigger shoe from the pistol grip—ergonomically similar to that on the PMR-30, RFB and RDB—is easy for shooters of various hand sizes. Recesses in the side of the pistol grip provide space to hold the two assembly pins during disassembly.

Spanning from the muzzle plate assembly rearward to the sleeve plate is an aluminum heat shield with Magpul M-LOK slots. Meanwhile, extending from the sleeve plate to the sight base itself, forward of the polymer heat shield, is a 30-slot aluminum Picatinny rail. Atop the rail is a windage-adjustable Magpul MBUS rear sight, which works in conjunction with an elevation-adjustable post front affixed to the muzzle plate assembly. Bilateral sling attachment points are found on the muzzle plate assembly, and a sling ships with the gun.

Although chambered in 12-ga., 3", the KSG-25’s stock is fitted with a 3/8"-thick, semi-hard rubber recoil pad. Minimally tacky, the pad doesn’t easily snag when shouldering the gun, nor does it reduce recoil very effectively.

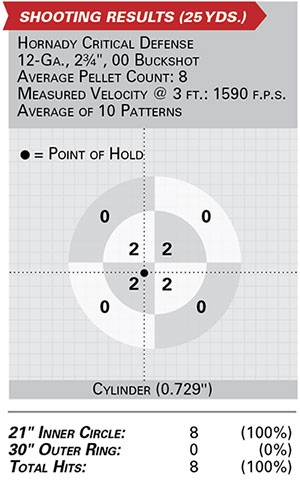

Evaluation of the KSG-25 began with patterning at 25 yds. using Hornady Critical Defense 2¾" 00 buckshot and the MBUS. Despite its cylinder-choke barrel, the KSG-25 kept all 80 pellets within the 30" outer ring of the patterning papers, and 75 within the 21" inner circle—ideal for self- or home defense.

With patterning completed, we transitioned to function testing and rapid-fire drills. As it’s chambered to handle 12-ga., 1½" to 3" shells, we proceeded to feed it a variety of target, heavy field, buckshot, slug and steel loads in lengths ranging from 2" to 3". In exhausting multiple partial and full boxes of each, we discovered that the shotgun must be cycled vigorously for reliable functioning, and on several occasions cycling damaged—or removed—a portion of the brass-washed steel head of the shell. Twice we had a shell lock up the action, requiring finesse to remove them.

Upon closer inspection, it was noted that two tabs integral to the molded polymer buttstock halves (one per side) had been broken. They appear to keep the shell centered on the carrier. The gun was sent to Kel-Tec, which promptly serviced and returned it. Accompanying the gun was a letter stating, “chamber service, adjusted swedge, replaced buttstock and carrier, [and] recommend high-brass ammo.” A subsequent range session revealed that Kel-Tec had successfully remedied the problem, as the gun cycled much smoother than before, and there was no damage to hulls, either.

The MBUS were a nice addition to the KSG-25. Moreover, we liked the gun’s downward ejection, as well as the ability to switch between magazines (should they be loaded with complementary loads, such as slugs and buckshot). The positioning of the magazine selector and left-to-right movement of the safety will take time to get used to, but, overall, the KSG-25 is a marvel in its own right.