Since its launch in 2015, the Ruger Precision Rifle (RPR) has transformed the landscape of the American rifle industry—swelling a wave of interest in long-range shooting while likewise providing mainstream exposure to the 6.5 mm Creedmoor that helped catapult the cartridge to the prominence it enjoys today. Prior to the rifle’s introduction, precision chassis-stocked turnbolts were essentially the exclusive province of a few custom, high-end builders. Despite not being a true chassis gun itself, the incredible success of the comparatively affordable RPR unleashed a deluge of competing models onto the market, as virtually every other major maker of center-fire rifles rushed to introduce its own offering—with some simply dropping their legacy actions into a cool-looking aluminum chassis stock and calling it a day. Yet despite the slew of outwardly similar rifles that have come in its wake, each gunning specifically for Ruger’s share of the pie, the model that first set the bar for the economical precision bolt gun still remains among the best of its type.

In this job I’m blessed to be able to partake in many different facets of the shooting sports. Enjoyable as each may be, I can say, without a shadow of a doubt, that long-range rifle shooting is my favorite by a mile. And given that interest in long-range competitive shooting disciplines, such as the Precision Rifle Series (PRS), is at an all-time high, it’s safe to say that I’m not alone.

So when I learned last summer that I would be making a return trip to FTW Ranch in Barksdale, Texas—home of the Sportsman’s All-Weather All-Terrain Marksmanship training course and its 12,000-acre campus—for four days of wind-bucking, steel-pelting goodness, I was immediately excited. When it was later revealed that I would be taking the trip in order to spend some time behind a hitherto unreleased magnum-chambered evolution of the RPR, I started counting the minutes.

You see, I’ve had my ear to the ground for this one for a while now. Back in 2015, I was among the small group of writers who got the first look at the original RPR prior to its announcement (August 2015, p. 50), and I took the opportunity to query Ruger’s director of product management, Mark Gurney, regarding if and when the platform would be expanding beyond the three short-action chamberings offered at launch. He assured me that a magnum-chambered version of the Precision Rifle was already planned, and I have waited (somewhat) patiently ever since. But now my watch is ended—and to my great relief—the magnum RPR has proven to be well worth the wait.

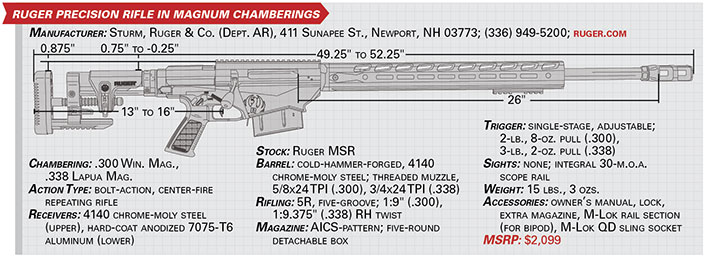

Unveiled in mid-October, the newest RPRs are being offered chambered in .300 Win. Mag. and .338 Lapua Mag., two cartridges with illustrious pedigrees in both competitive shooting and military sniping, and I was able to procure one of each for the purpose of this article. With a few exceptions, the most obviously apparent being the enormous 3.75"-long and 2"-wide tank brake affixed to the muzzle, the magnums are near-complete facsimiles of the original center-fire models—just scaled up in key dimensions in order to accommodate the new rifle’s much larger and more energetic cartridges.

Although chambered in several other options, the lion’s share (somewhere in the vicinity of 75 percent) of the short-action RPRs that Ruger has sold during the past three years have been 6.5 mm Creedmoors. The best-selling center-fire rifle cartridge in the world right now, the Creedmoor is revered, in part, due to the superb ballistic efficiency of its .264-cal. projectiles. They accomplish a lot, both externally and terminally, despite relatively middling kinetic energy levels. As a result, attendant recoil impulses are mild enough that even novices can tolerate them—another cause for the chambering’s appeal.

Factory loads span from 120 to 147 grs., with G1 ballistic coefficients (BCs) of match ammunition typically ranging between 0.486 and 0.658, and muzzle energies in the vicinity of 2,400 ft.-lbs. Yet as stingy as the 6.5 mm Creedmoor can be in regard to shedding its velocity while in flight, remarkably, the magnum RPR’s chamberings can be even more tightfisted—while also representing a significant step up energy-wise.

As today’s most popular .30-cal. magnum cartridge by a large margin, many (if not most) of the loads available for the .300 Win. Mag. are intended for use in hunting, and are not optimized for long-range shooting. Nevertheless, plenty of ammunition makers do offer low-drag match loads for the cartridge using longer, heavier projectiles, with bullet weights hovering around 200 grs., and boasting BCs even better than the Creedmoor—from 0.547 to 0.717—and with energies averaging about 3,500 ft.-lbs. at the muzzle.

The .338 Lapua Mag., on the other hand, was designed from the ground up as a long-range cartridge, and was actually developed, in part, at the behest of the U.S. Army, to address penetration concerns regarding the .300 Win. Mag. Primarily offered in 250- and 300-gr. match loads, the BCs of the former generally fall within the 0.587-0.685 range, while the latter possess extraordinarily aerodynamic G1 BCs between 0.720 and 0.822—both with muzzle energies way up around 4,700 ft.-lbs.

In comparing trajectories, using four similar loads from Federal’s Gold Medal Match line as an example, all topped with Sierra MatchKing projectiles, we can see that—despite its flat-shooting reputation—the Creedmoor is the first to trail off. When zeroed at 200 yds., the 140-gr. 6.5 mm Creedmoor (0.535 BC) drops 47.5" at 500 yds., while the 190-gr. .300 Win. Mag. (0.533 BC), 250-gr. Lapua Mag. (0.587 BC) and 300-gr. Lapua Mag. (0.768 BC) drop 39.9", 37.1" and 46.6", respectively, at the same distance. In terms of wind deflection, the magnums also get the nod. Subjected to a 10-m.p.h. crosswind, at 500 yds., the four above projectiles are knocked off course: 140-gr., 18.1"; 190-gr., 16.4"; 250-gr., 14.3"; and 300-gr., 12.8".

Of course, it’s difficult to offer any sort of true apples-to-apples ballistic comparison of two projectiles as dissimilar as a spindly .264-cal., 140-gr. projectile and a .338-cal., 300-gr. behemoth—and the above is a lone example within an immense market of ammunition offerings—however, it does illustrate the impressive capabilities of the RPR’s two newest chamberings. All this increased ballistic performance reduces hold-overs, shortens flight times and pushes the maximum effective range of the magnum RPR out beyond the distances where the short-action RPR’s cartridges start to fall short (although at the unavoidable cost of increased recoil and weight). Hence my eager three-year vigil for fresh news out of Newport: If efficiency is good, and raw power is good, then efficiency plus raw power is pure nirvana. Particularly if the firearm behind it all is controllable and accurate—qualities which I have discovered Ruger’s newest magnum to have in abundance.

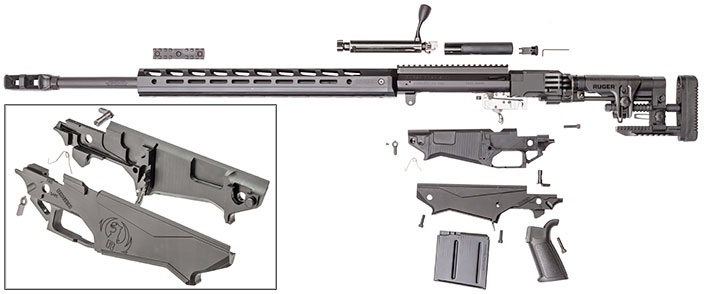

As mentioned above, in supersizing the RPR to create a magnum-chambered version, Ruger’s engineers didn’t change much about the design because, frankly, there was precious little about the original that required an overhaul. The magnum RPR is a push-feed bolt-action rifle, based on the company’s American action, housed within a purpose-built receiver that eschews traditional bedding in favor of a linear recoil path that transmits energy straight back through the in-line buttstock assembly. The new models retain all of the modularity of the short-action models, as the handguard, pistol grip, buttstock and bolt knob can all still be swapped out to suit the user’s preferences.

The rifle’s upper receiver and one-piece bolt body are CNC-machined from pre-hardened 4140 chrome-moly steel. The lower receiver, composed of 7075-T6 hard-coat anodized aluminum, is machined in two halves, a method that simplifies production by allowing the gun’s small parts to be placed into position in one side before the other half is installed in place. Despite the .338 cartridge being considerably longer and fatter than the .300, both versions of the rifle share the same scale, being built on identical receivers, and differing only in regard to those details specific to their chamberings (i.e. barrels, chambers, bolt faces, etc.).

One tweak made to the design in order to better harness the increased ballistic capabilities of its cartridges relates to the gun’s top rail. Whereas the original RPR features a 20-m.o.a.-canted Picatinny rail atop its receiver for the installation of an optic, the magnum iteration instead wears a 20-slot, 30-m.o.a.-canted section of rail (affixed via six No. 8-40 screws) for even more built-in elevation adjustments.

A beast of a rifle—the word honkin’ has been uttered on multiple occasions regarding the magnum RPR—it weighs in at 15 lbs., 3 ozs., naked, and once fully laden with a high-magnification scope, bipod and other ancillary equipment, shooters can expect the gun to tip the scales in the vicinity of 20 lbs. Comparing this to the short-action RPR, no featherweight itself—which comes out of the box at 10 lbs., 10 ozs., and is around 15 lbs. fully dressed—demonstrates pretty clearly just how much beefier the new rifle is given that the guns’ overall lengths are quite similar (once you account for the longer barrel and the elongated muzzle device).

Ruger’s American action utilizes a 70-degree bolt throw that is easy to articulate while prone or from the bench, yet also provides adequate scope clearance. The magnum RPR’s full-diameter, three-lug bolt travels within the rifle’s AR-style receiver extension during manipulations, so there’s no fear of it coming into contact with the shooter’s face and, therefore, no need to break cheekweld while racking the bolt. For the benefits of increased wear- and corrosion-resistance, as well as lubricity, the entire bolt body has been subjected to a black nitriding treatment.

A sliding-plate extractor found within the bolt head’s 10-o’clock lug pulls the cartridge clear of the chamber, and a plunger-style ejector opposite it at the 4-o’clock position on the bolt face then expels the case through the right-side ejection port. The rifle cocks upon opening, and a bolt-release lever on the left side of the upper receiver allows the bolt to be withdrawn from the gun, however, the buttstock must be folded out of the way in order to do so.

Both chamberings of the new rifle feature 26", cold-hammer-forged, 4140 chrome-moly steel barrels that utilize right-hand 5R rifling and come with Ruger’s distinctive new muzzle brake. Each magnum RPR barrel is of a heavy contour, measuring 0.875" in diameter at the muzzle, and floating freely within its handguard. As with the original RPR, the barrels attach to the receiver via a barrel nut, and can be replaced by a decent gunsmith using AR-style tools. The .300 Win. Mag. model’s tube is rifled at a 1:9" twist rate and is threaded 5/8x24 TPI at the muzzle to accept the majority of .30-cal. suppressors and accessories, should the user decide to remove the factory brake. On the other hand, the .338 Lapua Mag. guns are rifled 1:9.375" and threaded 3/4x24 TPI—a common, but not universal, thread pitch for .338-cal. muzzle devices.

Ruger is making the tank brake in-house, casting the 4140 steel body at its Pine Tree Castings operation and then machining the device to final form in its manufacturing cell with the rest of the rifle. Four cavernous side baffles very efficiently re-direct escaping gases laterally, while four ports drilled into the top of the symmetrical brake can be opened or closed, allowing the user to tune the rifle for minimized muzzle jump. Although it may eventually be offered aftermarket, for now, the accessory is exclusive to the magnum RPR.

Unlike the short-action variant, which can feed from both rear- and side-latching detachable box magazines, the magnum accepts only rear-latching, single-stack, AICS-pattern boxes, using the bolt’s 6-o’clock lug to strip a cartridge from the magazine’s feed lips and load it into the chamber. Each rifle ships with two five-round Accurate-Mag SSSF magazines of the appropriate cartridge—the 3.850" magazines being long enough to accommodate any CIP- and SAAMI-spec cartridges of either chambering.

Accordingly, the magnum RPR features a simplified magazine-release system compared to its forebear, as it has no need to facilitate the use of side-latching magazines. Instead, a simple pivoting release lever, located just forward of the trigger guard, trips only the Accurate-Mag’s rear latch. Magazines lock into place using only upward pressure, and they fit snugly enough within their well to require manual assistance from the shooter when the release lever is depressed for removal. Also differing from its predecessor, the magnum’s bolt does not lock back on an empty magazine due to differences in the designs of the magazines’ followers themselves.

One of the few components not scaled-up in the magnum RPR is the fire control group, as it shares the same Marksman trigger system present in the short-action RPR. A user-adjustable design with a safety blade bisecting the trigger shoe that must be depressed before the trigger will release, the Marksman’s single-stage break can be set by the user to any weight between 2 lbs., 4 ozs., and 5 lbs.

This can be accomplished without disassembling the rifle by inserting a hex key, cleverly incorporated into the rear of the bolt shroud, through the magazine-release lever and into the trigger’s adjustment screw. Both of our test samples exhibited admirable triggers, with light, crisp breaks—at 2 lbs., 8 ozs., on the .300, and 3 lbs., 2 ozs., on the .338—and zero discernible take-up or overtravel.

Attached via a mil-spec, carbine-length AR-style receiver extension, the magnum RPR employs the same buttstock assembly as does its progenitor—Ruger’s proprietary Precision MSR unit. This buttstock allows for quick, repeatable alterations to the rifle’s length of pull, comb height and buttpad cant; the former two are accomplished by unlocking a pair of cam levers located on the side of the stock, adjusting the stock to the desired setting and then re-tightening the levers. In all, the Precision MSR allows for to up 3" of length-of-pull adjustment (between 13" and 16") and 1" of comb-height fine-tuning.

In addition to upward and downward motion, the rifle’s cheek pad can also be moved forward and rearward along the stock, and can be reversed so that it extends toward the aft of the rifle rather than the muzzle. Cant is customized by removing the rubber recoil pad, loosening the bottom of two exposed screws and removing the top one, shifting the stock to the desired orientation (up to nine degrees in either direction is possible), then re-tightening both screws and re-installing the pad. The Precision MSR also features a reversible QD sling socket, a five-slot section of Picatinny rail along its bottom surface for the optional installation of a monopod and a 1.5"-thick soft rubber recoil pad.

Given its utilization of a standard receiver extension, the magnum’s factory stock can be replaced with any mil-spec AR-15-compatible unit of the shooter’s choice. A hinge incorporated into the receiver allows the buttstock assembly to be folded along the left side of the receiver and locked in this position for easier transport, decreasing the rifle’s length to a more manageable 40.35".

The magnum RPR’s 18"-long, 2.25"-wide hard-coat anodized aluminum handguard bears M-Lok slots along its 3-, 6-, 9- and 12-o’clock surfaces, and a pair of QD sling mounts on each of these sides but the top. New to the magnum, the larger gun’s handguard also features a 1.5" dovetail machined into its bottom face that is compatible with accessories that use Arca-Swiss-type mounts. Initially developed for use within the photography industry, this system has caught the attention of many PRS competitors, and—according to Gurney—if well received by the shooting community on the magnum RPR, may also find its way onto the short-action RPRs as well. As previously mentioned, the handguard is user-replaceable—however, as it’s compatible with the larger AR-10 platform and not the much more abundant AR-15, substitute fore-end options for the magnum will not be as plentiful.

Rounding out the rifle’s furniture is the same extended-reach AR-style pistol grip found on the original version, although, again, it can be swapped out to suit the user’s druthers. Early-model short-action RPRs, like the one I evaluated, made use of a one-sided-but-reversible 45-degree safety selector, however, both the late-model short-action rifles and the magnums come with bilateral 45-degree safeties.

Some southpaws will bemoan the lack of left-hand models, but, despite being a lefty myself, for the long-range and benchrest applications for which the magnum RPR will predominantly be used, I personally strongly prefer a right-hand action. This allows me to run the bolt with my support hand without coming off of the trigger, greatly decreasing the amount of time between shots. And unfortunately for southpaws still holding onto hope that Ruger will one day deliver the reversed action for which they have been waiting, Gurney indicated that neither left-handed short-action nor magnum RPRs currently figure into the company’s future plans. Sorry, guys.

Function testing began in the Texas Hill Country and continued back at NRA Headquarters. At FTW, I only had the opportunity to field test the .338 version, but back home both chamberings were shot extensively on the NRA Publications’ Test Range—although after having had occasion to ring steel at extreme long range with the magnum-chambered RPR, firing these rifles on paper at close range does feel vaguely inappropriate.

While in Texas, I was able to score hits on one-m.o.a. targets all the way out to 1,823 yds. (1.036 miles) despite hellacious, shifting, 25-m.p.h., summer crosswinds, although my attempts at the 2,500-yd. steel under the same circumstances were unsuccessful. A better shooter, with more favorable winds, would no doubt be able to successfully employ the magnum on shots out beyond a mile with regularity.

Generally speaking, how well a shooter can operate a magnum rifle is ultimately dependent upon his or her ability to endure recoil, as a flincher has no chance of keeping the rifle stable enough throughout the firing process in order to make consistent strikes on a target located far afield. However, the magnum RPR’s considerable weight and effective muzzle brake largely take recoil out of the equation, as they combine to render the rifle remarkably pleasant to shoot—a term that can rarely be applied to firearms producing this much power.

Just recently, I conducted testing of a 7-lb., unbraked .30-’06 Sprg.-chambered hunting rifle, and subjectively, I find the .338 Lapua Mag. Ruger to be slightly more comfortable to shoot for prolonged periods—producing more of a slow push than a sharp kick. And if the .338 is surprisingly agreeable, the .300 is an absolute pussycat. To say that the rifle is tame enough to allow you to watch your hits through the scope would be an exaggeration for most shooters, but for shots in excess of 1,000 yds., after pulling the trigger, using the .338, I was easily able to get back on target in time to check for impacts.

A highly capable muzzle device does present a down side, however, as the noise and lateral blast created by the magnum RPR is, for lack of a better word, epic. While not much of an issue for outdoor excursions—consider investing in a quality shooting mat to minimize ground disturbance—testing conducted on an indoor, one-stall test range was thunderously loud, and the blast was sufficient to knock several small items and papers from a nearby desk. In such an environment, I strongly recommend doubling-up on your ear protection and being cognizant of (and respectful toward) your neighbors.

In putting approximately 200 rounds through each rifle, neither of the new RPRs exhibited any malfunctions. Longer cartridges obviously require greater bolt travel, which made for slower cycling of the magnums than I am accustomed to in my well-broken-in 6.5 mm Creedmoor RPR, but, for a fresh-from-the-box bolt gun, the rifles’ actions were smooth, and should become even more so with use. Given the ubiquity of the AR-15 within the contemporary gun world, use of the magnum RPR’s safety will be second-nature for most shooters—which cannot be said of many of the Ruger’s competitors that I have encountered.

When shooting for accuracy, the .300 Win. Mag. was outfitted with a Leupold Mark 5HD 5-25X 56 mm scope, an Accu-Tac SR-5 QD bipod and an Accu-Shot BT12-QK monopod; the .338 Lapua Mag. was accessorized with a SIG Tango6 5-30X 56 mm scope, a GG&G Quick Detach Heavy Duty XDS bipod and a CTK Precision Ultimate Rail-Pod monopod. Testing followed this magazine’s established protocol of five consecutive, five-shot groups using three different types of ammunition. Each rifle demonstrated exemplary accuracy, with only two of the 30 combined groups exceeding the modern 1" benchmark.

On average, the .300 Win. Mag. edged out the .338 Lapua, managing a 15-group average of 0.77" compared to the 0.80" average produced by the larger cartridge—however, the smallest group of the day (0.44") belonged to Federal’s .338 load. These results are remarkably consistent with our prior evaluation of the 6.5 mm Creedmoor-chambered RPR, which managed an average extreme spread of only 0.76".

For the sake of simple practicality, given the far greater availability of .300 Win. Mag. ammunition compared to .338 Lapua Mag.—and its much more modest price tag when it is encountered—I suspect the .300 magnum RPR will ultimately sell in larger numbers for Ruger than the .338. However, I believe there are more than enough die-hard extreme-long-range shooters out there, insatiable as they can be in their efforts to maximize ballistic performance and extend their range, to keep demand for the .338 humming along steadily, despite the cost of feeding it.

And speaking of price, the magnum RPR will retail for $2,099, a not inconsiderable $500 markup relative to the short-action rifle, but not too bad at all when you consider that a muzzle device like the one employed by this firearm will often cost several hundred dollars alone on the aftermarket. Not to mention how much more expensive the bigger rifle’s AICS-type magazines (of which two ship with the gun) are than the original RPR’s PMAGs. While unquestionably a sizeable investment, with a likely eventual price at the counter south of $2,000, the new rifle nonetheless offers substantial value, as a brief appraisal of the limited magnum-chambered chassis-gun market reveals this figure to reside on the far low end of the price spectrum.

The new RPR in magnum cartridges retains everything that made the original gun worthy of this publication’s 2016 Golden Bullseye Award for Rifle Of The Year: utter dependability, a high degree of modularity, phenomenal accuracy and relative affordability. That the magnum does so while hitting harder, reaching farther and making bigger holes—yet remaining eminently shootable—sounds like a win-win-win scenario to me.