A sea change in defensive shotgun design has occurred during the past decade. Beyond upgrading existing platforms, the trend has been to find unconventional ways to maximize firepower from a small platform. One such firearm that embodies this movement is the subject of this review, the Standard Mfg. Co. DP-12.

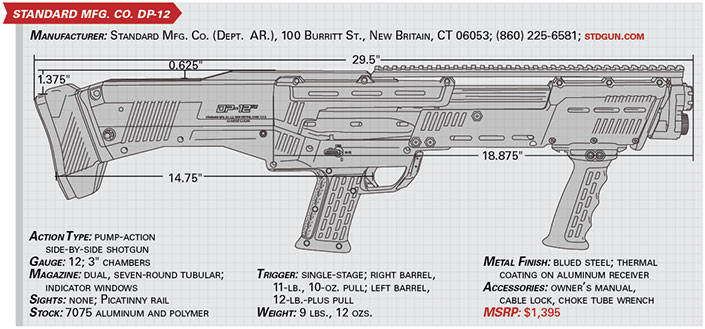

The DP-12 is a bullpup-style, pump-action, side-by-side, 12-ga. shotgun with dual magazine tubes. Essentially, it combines the handiness and rapid firing of a Western-style “coach gun” with the sure functioning and firepower of a pump-action shotgun. Since the action is located behind the trigger group and integral with the buttstock, the gun measures only 291/2" long while featuring twin 187⁄8" barrels.

The DP-12’s barrels are machined from round bar stock, and they flare considerably approaching the aluminum muzzle support. Chambered for 12-ga., 3" shells, the barrels are threaded to accept Tru-Choke-pattern choke tubes. A “Max Spreader” choke tube is provided for each barrel. Shells measuring less than 2¾" in length are safe to use in the DP-12; however, the company recommends testing for functionality before pressing these diminutive loads into service. Tubular magazines that facilitate in-line feeding are located beneath the barrels. Each magazine holds seven 2¾", 12-ga. shells, bringing the total capacity to 16 rounds when two rounds are chambered. Shell indicator windows in the magazines permit visual confirmation of the rounds remaining. The oversize loading/ejection port is located behind the pistol grip and forward of the butt.

The DP-12’s receiver is machined from aircraft-grade 7075 aluminum. Company literature reports that it has a thermal coating, too—given the DP-12’s potential high rate of fire, that’s a prudent decision. Since the bolts lock up with steel barrel extensions, and thus the receiver is subject to minimal stress, the use of aluminum there is justified. At the front of the receiver is a black, two-piece, polymer shroud to protect the shooter from heat. Extending from the top of the receiver to the shroud is an aluminum rail that provides rear support for a 13¾" (34-slot) section of Picatinny rail. The latter, which is also crafted from aluminum, is secured at the front to the muzzle support. Open sights aren’t provided.

Beneath the receiver—and extending from the pump pad shroud forward more than half the gun’s length—is the grip assembly, which, like the shroud, is made from two halves. In addition to the ejection/loading port, the grip assembly contains the fire controls. The bilateral, two-position safety mimics that on AR-pattern rifles. Creep of the single-stage trigger was nonexistent, and reset was surprisingly short, too; however, the pull weight was exceptionally heavy, as is often the case with bullpup designs. Whereas the trigger broke on the right barrel at 11 lbs., 10 ozs., the left barrel exceeded the 12-lb. limit of the trigger-pull gauge. The action release lever is located on the front of the trigger guard and is actuated by pulling down.

The thinness of the DP-12’s pistol grip and flaring nearing its bottom enable a solid purchase. Further enhancing grip are raised sections on each side of the pistol grip and urethane strips adjoined to the backstrap. The gun’s center of gravity is located directly above the pistol grip. At the bottom of the two-piece, polymer fore-end is a seven-slot, 33⁄8" section of Picatinny rail to which a composite grip handle is attached. Thanks to the six slots on the fore-end, there are 18 total slots on the gun to add Magpul Original Equipment (MOE) rails.

Beneath the thin, rubber recoil pad are dual recoil springs. Given the gun’s 9-lb., 12-oz. empty weight, recoil-mitigating enhancements probably aren’t necessary for anything but the stoutest 3" loads. Operationally, the DP-12 isn’t too unlike single-barrel pump-action shotguns. Once the DP-12’s magazines are charged, the action bar release is pressed, permitting the fore-end to travel rearward, extracting and ejecting empties downward (if present) and allowing fresh rounds to slide onto the carrier. Pushing the fore-end forward advances the new shells into the chambers and then completes lock-up.

Pulling the trigger fires the right barrel, and a subsequent press discharges the left tube. Instant access to a second round is assured; should the first shell (in the right barrel) fail to discharge, the left barrel is prepared to fire.

To test the DP-12 we topped it with a TruGlo multi-reticle/dual-color, open-dot-style sight and utilized the provided 0.725" “Max Spreader” tubes. Due to the DP-12’s primary use as a defensive arm, we opted to pattern test it using Suprema 12-ga., 2¾" 00 Buck, which featured nine lead pellets. The results are tabulated nearby, and were impressively tight given the distance to the target.

With patterning completed, we then fed the DP-12 a diet of shells from myriad makers—ranging from 1¾" Aguila Minishells to 3" Remington Nitro Magnum waterfowl loads. Regardless of the order in which they were loaded, the DP-12 fed, fired, extracted and ejected all shells tested flawlessly. As with other pump-action shotguns, the action should be cycled with vigor.

As can be expected from a shotgun weighing nearly 10 lbs. and measuring nearly 3" wide, the DP-12 is not as fast on target as is a single-barrel shotgun. Immediate access to a second round and greater capacity, however, more than offset that negative. Lastly, even ardent pump-action shotgunners may struggle with the DP-12 at first; used to working the slide after each shot, doing so on the DP-12 is an act of futility. Only through practice will the ingrained habit change.

Standard Mfg. Co. has created a compact shotgun with unparalleled firepower that’s sure to be appreciated by the defensive-minded homeowner. Beyond personal protection, the shotgun would excel for feral hog hunting and pursuing snow geese during the conservation season, too.