Introduced in 1950, the Remington Model 870 Wingmaster was the gun of the future. Part of a modernization program for Remington, it was announced at the same time as the semi-automatic Model 11-48. Touted as “A Fine New Pump at an Amazingly Low Price!” the 870’s receiver was sleek, and the bolt locked into a hardened-steel barrel extension (not the receiver), which has become a hallmark of nearly every pump gun since. A replacement for the Model 31, the 870 featured a smooth action and dual action bars running between the barrel and the tubular magazine. Not only did the 870 have style, it had an attractive price, thanks to having some parts soldered or riveted together to ease assembly time and cost. Designed to compete against the old-school Winchester Model 12, the 1 millionth Model 870 was made in 1966—two years after the venerable Model 12 was out of production.

Introduced in 1950, the Remington Model 870 Wingmaster was the gun of the future. Part of a modernization program for Remington, it was announced at the same time as the semi-automatic Model 11-48. Touted as “A Fine New Pump at an Amazingly Low Price!” the 870’s receiver was sleek, and the bolt locked into a hardened-steel barrel extension (not the receiver), which has become a hallmark of nearly every pump gun since. A replacement for the Model 31, the 870 featured a smooth action and dual action bars running between the barrel and the tubular magazine. Not only did the 870 have style, it had an attractive price, thanks to having some parts soldered or riveted together to ease assembly time and cost. Designed to compete against the old-school Winchester Model 12, the 1 millionth Model 870 was made in 1966—two years after the venerable Model 12 was out of production.

Introduced in 12, 16 and 20 gauges, there were 15 inaugural versions with prices ranging from $69.95 for the 870R AP Standard and Riot Grades all the way up to the Model 870TF Trap Premiere Grade with a sticker of $678.55. Five years later, the Model 870-AP Standard and Magnum ADL-Deluxe Magnum were chambered for the 12-ga., 3" magnum. A rifled version, the Model 870 RSS, with rifle sights, came out in 1955.

The .410-bore and 28-gauge versions were added in 1969 on receivers specifically scaled for those diminutive shotshells. Southpaws got their own 870s in 12 and 20 gauges two years later. Rem Choke interchangeable choke tubes were added to the 870 in 1986. Embracing the 12-ga., 3½" magnum shotshell in 1998, Remington announced the Model 870 Express Super Magnum.

The Model 870 has endured relatively few major changes to how the gun is made, but as with anything that has been manufactured for 67 years, the variations are legion—stocks, finishes, barrel ribs, beads, sights, barrel lengths, combos, sets, etc. Too, some parts once made of metal are now made of polymer, such as the trigger guards on Express models.

The Model 870’s success with hunters and shooters is unquestioned, although it has had limited U.S. military procurement. That said, it remains ubiquitous as a law enforcement shotgun. The gun’s receiver has always been well-suited for embellishment, and 870s have commemorated everything from Ducks Unlimited to Dale Earnhardt to the company’s 200th anniversary—celebrated last year.

As of this writing, more than 11 million Model 870s have been made in Ilion, N.Y. It remains the most-produced shotgun in history, and it likely will for some time to come. Sixty-seven years later, the 870 lives up to its original slogan, “tops in the blind and field.”

Disassembly

Depress the action bar lock (56) and move the fore-end (32) to the rear. Inspect both the barrel’s (1) chamber and the rear of the magazine to ensure the gun is unloaded. Once certain the gun is unloaded, move the fore-end forward. To remove the trigger plate (53) and assembly, first set the safety (51) on “safe,” then drift out the front and rear trigger plate pins (21 and 22) (FIG. 1). (When replacing these pins, holes in the trigger plate and receiver (15) must be properly aligned and show clear passage.)

Next, lift the rear end of the trigger plate from the receiver (A). Then, slide the unit rearward (B), turning it clockwise to clear the action bar lock (FIG. 2). When re-assembling the trigger plate assembly, the rear end of action bar lock must go below end of left connector (46) for the gun to function properly.

To remove the barrel assembly, including the barrel extension (6), if the gun is cocked, press the action bar lock upward. Move the fore-end half way back to open the action. Unscrew the magazine cap (11), remove it and then pull the barrel assembly from receiver (FIG. 3).

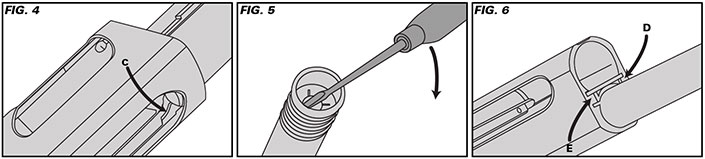

To remove the fore-end assembly, including the fore-end, breech bolt (70), locking block (68), slide (64), etc., press in on the front end of the left shell latch (33) (C) and slide the assembly forward off the magazine tube (13) (FIG. 4). The barrel must first be removed to affect this operation.

To remove the magazine spring (14) and the magazine follower (17), insert the blade of a small screwdriver into the hole in the spring retainer (12) and pry the retainer from the magazine tube (FIG. 5). Remove the retainer slowly to relieve tension on the magazine spring. The spring and follower may now be removed.

Re-assembly is in the reverse order. Assemble the slide to the action bars (28 and 29), together with the breech bolt assembly. Assemble the fore-end tube (30) over the magazine tube and insert the rear end of the action bars (with the slide and breech bolt assembly on them) into the receiver grooves (D and E) (FIG. 6). Move the assembly rearward gently until it contacts the front end of the right shell latch (34). Press in on the right shell latch to clear the action bar and slide the fore-end gently rearward again until it contacts the left shell latch. Press in the left shell latch and push the fore-end rearward until it is stopped by the action bar lock.