The most iconic and well-known submachine gun of all time is unquestionably the Thompson. First put into production in 1921, the Thompson initially gained a measure of notoriety in the hands of G-Men and nefarious criminal elements in the late 1920s and early 1930s. It also saw limited military service during this same period, primarily with the U.S. Marine Corps, in various hot spots around the globe, such as the “Banana Wars” in the Caribbean and Central America, as well as China. By the time war broke out in Europe in 1939, the Thompson was the only submachine gun available to our armed forces and those of our allies. It was effective but had two major drawbacks; it was expensive and time-consuming to manufacture and, at about 11 lbs., was quite heavy for a gun of its type. The variant in production early in World War II, the Model 1928A1, was subsequently modified to reduce manufacturing time and expense, which resulted in the simplified M1 and M1A1. While they could indeed be made faster and at lower cost than the M1928A1, they continued to require an inordinate amount of machining, and their weight was only marginally less than the original model.

The British were the recipients of rather large numbers of Model 1928A1 Thompsons early in the war when no other submachine guns were available. But the British soon began development of a gun that could be made for a fraction of the cost and in a fraction of the time. The result was the utilitarian Sten 9 mm Luger submachine gun, which was composed largely of stamped and welded sheet metal. It was crudely made but proved to be functional, and eventually replaced most of the Thompsons in British service. The Germans had developed the MP 40 Maschinenpistole, which made extensive use of stamped parts and was widely used by the Wehrmacht throughout the war. From all indications, the MP 40 functioned just as well as its predecessor, the finely machined MP 38.

Although the advantages of the Sten were not lost on the U.S. Army Ordnance Dept., its crude appearance offended the sensibilities of some hide-bound American Army officers who were accustomed to finely machined and meticulously crafted guns, such as the Thompson, M1 Garand and Browning Automatic Rifle. In the minds of many, it was believed that guns made from stamped and welded sheet metal were inherently inferior to more traditional arms. But such suppositions were secondary to other considerations. An Ordnance report written soon after the U.S. Army’s initial tests evaluated the Sten in the following manner:

“Guns of the STEN series had been tested at Aberdeen Proving Ground and had been criticized because of this highly unorthodox appearance. The STEN demonstrated, however, that an efficient submachine gun could be made at small unit cost and by rapid production-line methods. Officers of the Small Arms Development Branch realized that in modern warfare there are other criteria than mere appearance. They knew that huge numbers of arms of this type would be required and directed all efforts toward the production of a gun which could be manufactured as easily, as swiftly, and as economically as the STEN.”

Inspired, at least in part, by the Sten, the U.S. Army Ordnance Dept. embarked on a program to develop a submachine gun that could be made faster and cheaper than the Thompson. A Brooklyn, N.Y., gun designer, George J. Hyde, had patented a submachine gun in 1935. Working in conjunction with the Inland Manufacturing Division of General Motors, which wanted to diversify into manufacturing military firearms, Hyde’s design was resurrected and improved. The gun, designated as the “Hyde-Inland 1,” was submitted to the Ordnance Dept. for testing in April 1942, and initial evaluation revealed that improvements were warranted. A modified version, the “Hyde-Inland 2,” was re-submitted.

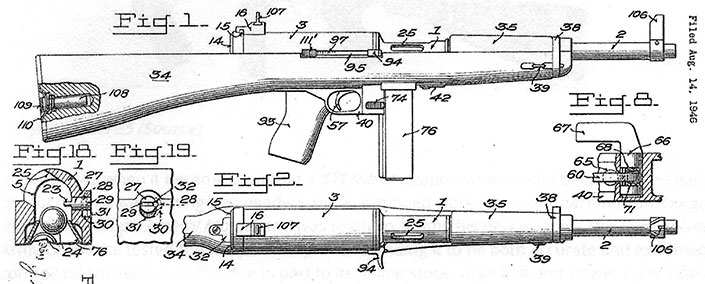

The Hyde-Inland submachine gun had a wooden stock and handguard, with a fixed rear aperture sight with protective “ears” on either side. The barrel was 12.1" long and the overall length was 32.1". Firing from an open bolt and chambered in .45 ACP, it was designed to utilize the standard 20- or 30-round Thompson box magazines. The Hyde-Inland gun could fire in either semi-automatic or full-automatic modes at a rate of approximately 570 rounds per minute. The gun weighed about 9 lbs., 4 ozs.—almost 2 lbs. lighter than the hefty Thompson. More importantly, it was believed it could be made much faster—and at a lower cost—than the Thompson.

During the testing at Aberdeen in April 1942, the Hyde-Inland 1 fired 6,080 rounds during the endurance firing phase with 20 malfunctions, 15 of which were failures of the bolt to remain open after the last round was fired. The gun was deemed superior to the M1928A1 and M1 Thompsons in mud and dirt tests. During full-automatic firing, it was judged to be more accurate than any of the other submachine guns tested at the time. When five improved Hyde-Inland 2 guns were tested in June 1942, 2,640 rounds were fired with only two malfunctions. The Hyde-Inland 2 gun was classified as “Substitute Standard” in April 1942 and designated “Gun, Submachine, Caliber .45, M2.” Since Inland had become heavily involved in manufacture of the M1 carbine by this time, the Marlin Firearms Co. was given a production contract for 164,500 M2 submachine guns at a cost of $38.58 each.

The M2 was designed to utilize powder metallurgy to lower costs and increase the rate of production, but that proved to be unsatisfactory. Marlin had never used this manufacturing process and experienced a great deal of difficulty adapting to the new material. Eventually, it was decided to re-design the gun to utilize standard machined steel, which took some time to accomplish. This change eliminated the major advantages of the M2—faster production at lower cost.

The M2 was designed to utilize powder metallurgy to lower costs and increase the rate of production, but that proved to be unsatisfactory. Marlin had never used this manufacturing process and experienced a great deal of difficulty adapting to the new material. Eventually, it was decided to re-design the gun to utilize standard machined steel, which took some time to accomplish. This change eliminated the major advantages of the M2—faster production at lower cost.

Subsequent testing performed on the new Marlin-made M2 submachine guns revealed some troublesome functioning problems that had not shown up with the prototype Inland-Hyde guns. Numerous changes were made, but the modified guns continued to exhibit an excessive number of malfunctions. Due to the production problems and performance issues experienced by Marlin, the first M2s were not received by Ordnance until May 1943.

Possibly anticipating some problems with the M2, in mid-1942 the Ordnance Dept. had decided to hedge its bets while the new submachine gun was being developed. Colonel Rene Studler, George Hyde and Frederick Sampson collaborated on the design of another new submachine gun that, like the Sten, was made almost entirely from stamped and welded sheet metal. These efforts culminated with the development and adoption of the “Gun, Submachine, Cal. .45, M3.”

Due to the positive attributes of the new M3 sub-machine gun, Marlin’s contract for the M2 was cancelled on June 9, 1943, by which time only about 400 of the guns had been produced.

In his book, Ordnance Went up Front, author Roy Dunlap recalled seeing the M2 submachine gun at Aberdeen Proving Ground in 1942 and alluded to the gun that would be its replacement. He also commented on one positive virtue of the M2—its straight-line stock, which made it more controllable when firing in the full-automatic mode: “I saw these (M2 submachine guns) at Aberdeen Proving Ground early in 1942, and they were listed in some ordnance catalogs, though apparently, they never went into quantity production being superseded by the cheaper M3 … I think these M2s would have been very good guns so far as control of the arm in shooting was concerned.”

The fate of the relatively few M2 submachine guns made is not known, but existing specimens are quite rare, and it is likely most of the guns were destroyed. There is no evidence of any issuance or combat use of the gun by American troops in World War II.

The M2 submachine gun proved to be a failure at its intended purpose. Although the functioning problems that plagued it could likely have been corrected, the high expectations that the gun could be made faster and less expensively than the Thompson did not come to fruition. Eventually, those expectations were fulfilled with the development and adoption of the stamped and welded M3 “Grease Gun.” Thus, the M2 submachine gun has been relegated to a few museum showcases. It does, however, represent something of a missing link between the expensive and superbly crafted Thompson and the inexpensive but crudely made “Grease Gun” in the evolution of the World War II American submachine gun.