The U.S. M1A1 Carbine had a folding stock and was intended for issue to American Airborne troops during World War II. These troopers in Europe in 1944 have M1A1s.

This article was first published in American Rifleman, November 2005

The arm that holds the distinction of being manufactured in greater numbers than any other U.S. military firearm of World War II is the “U.S. Carbine, Caliber .30, M1.” The carbine represented a new category of service arm, initially intended to replace both the .45 ACP pistol and the Thompson submachine gun. Developed in 1941 by Winchester Repeating Arms Company and adopted after an exhaustive series of trials by the U.S. Army Ordnance Department, the carbine was a lightweight (roughly 5½ lbs.) semi-automatic shoulder arm that fired a .30-cal. cartridge fed from a detachable, 15-round box magazine.

The carbine was chiefly intended for issue to military personnel—including some officers—who would have been too burdened by the heavy M1 Garand rifle to carry out their primary duties. By the time production ceased in 1945, some 6 million carbines had been manufactured by 10 different prime contractors, and carbines were widely issued in all theaters of the Second World War.

As production continued, several variants of the M1 carbine were developed, including a selective-fire version—the M2—as well as a model designed to mount an infrared night-vision sight, the T3. However, other than the standard M1 Carbine, the variant that was manufactured in greater numbers, and which saw the widest issuance, was the “U.S. Carbine, Caliber .30, M1A1.” The M1A1 Carbine was designed for use by paratroopers and had a folding wire stock, which reduced the overall length when folded. The stock was fitted with a wooden pistol grip. The only difference between the standard M1 Carbine and the M1A1 carbine was the folding stock on the latter.

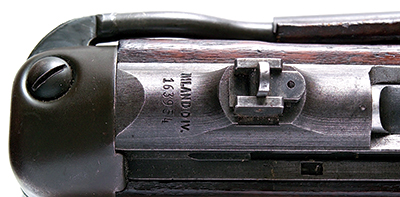

The M1A1 was officially standardized in May 1942, and the first deliveries began in October. The sole manufacturer of the M1A1 was the Inland Manufacturing Division of General Motors in Dayton, Ohio, which was also the largest manufacturer of standard M1 carbines. Inland produced about 43 percent of the total production of all carbines. In addition to M1s and M1A1s, the company produced the M2 and T3 variants. The initial subcontractor for the special M1A1 stock was Royal Typewriters, Inc., in Hartford, Conn. The wooden components of the stock were supplied by the S.E. Overton Company of South Haven, Mich., and Royal produced the wire butt and assembled the completed stocks. Royal apparently experienced some problems in its capacity as the lead subcontractor, and eventually, Overton assumed responsibility for assembling the M1A1 stocks and shipping them to the Inland factory.

There were two separate production runs of M1A1 Carbines. The so-called “First Contract” carbines were shipped between October 1942 and October 1943, with approximately 71,000 M1A1s delivered during the period. Serial numbers ranged approximately from 42,000 to 850,000. These M1A1s had the same features as the standard M1s of the era, including non-adjustable, flip-up rear sights; “high-wood” stocks (the area in front of the operating slide); narrow barrel bands (without bayonet lugs); and flat-top bolts.

The second production run was between about May and December 1944 and created less than 70,000 M1A1s. Serial numbers ranged approximately from 5,150,000 to 6,700,000. Although the basic design of the M1A1 stock did not change, the majority of the “Second Contract” stocks had “low-wood” and a slightly different shape to the grip. Also, during the course of production, many of the later production carbines (M1 and M1A1) were fitted with improved components, such as adjustable rear sights, round bolts and wider barrel bands. There is some disagreement whether or not any of these carbines originally left the factory with T4 barrel bands (with the bayonet lug). If so, only extremely late production M1A1 Carbines would have this feature, and the vast majority had either the narrow Type 1 or the wider Type 2 barrel bands (both types without bayonet lugs).

It must be stressed that the previously mentioned serial number ranges were only approximations, and there were no special serial number ranges assigned to the M1A1 production runs. M1A1 serial numbers were intermixed with standard M1 Carbines made by Inland during these periods. Therefore, as long as an Inland carbine is in the general serial number ranges already mentioned and has features consistent with the vintage of the stock, it is not possible to ascertain if an Inland action was originally mated with a M1A1 stock at the factory. Unfortunately, there is no known roster of M1A1 carbine serial numbers.

The M1A1 Carbine was generally issued with a padded canvas jump scabbard that attached to the pistol belt. The lower portion of the case could be strapped to the paratrooper’s leg during descent. Upon landing, the carbine could be quickly removed from the case, the stock opened and the gun ready for immediate use. Reportedly, the leg strap on the canvas case was rarely secured as it could cause injury (including broken legs) upon landing. Some paratroopers simply tucked the folded carbine behind their emergency parachute, or carried it in some other manner and dispensed with the jump scabbard altogether. The 15-round carbine magazines could be carried in either the standard two-cell, factory-made belt pouch or in rigger-made pouches fabricated by airborne unit riggers. These specially made pouches could hold either four, 15-round carbine magazines or three, eight-round Garand clips. Such pouches enabled more magazines to be carried on a paratrooper’s belt than was possible with the standard pouches. Similar rigger-made pouches were also constructed for the 20-round Thompson submachine gun magazines. M1A1 Carbines used the same type of sling as standard M1 Carbines.

As production allowed, the M1A1 Carbines were issued to all U.S. Army paratroop units, and they saw use in every American airborne operation of World War II, including Sicily, Normandy (D-Day), Market Garden and Operation Varsity (Rhine Jump). Limited numbers of M1A1 Carbines were also issued to the U.S. Marine Corps’ First Parachute Regiment, although the Marine paratroopers were never deployed in combat via airdrop. Not all paratroopers utilized M1A1 Carbines, and some were issued standard (full-stock) M1 Carbines instead.

The folding metal stock of the M1A1 Carbine was not well suited for launching rifle grenades due to the heavy recoil generated, which could bend or break the folding metal assembly. Regulations stated that the M1A1 was not to be used for grenade launching duties—except in emergency situations. If required, the recommended procedure when launching rifle grenades was to fold the stock and place the pistol grip of the carbine firmly on the ground.

Within the design parameters of the carbine, it performed adequately. It was only found lacking when compared to the venerable M1 Garand rifle, but the carbine was never intended to be a replacement for the rifle. Other than the limited-issue Marine Corps’ Reising Model 55 submachine gun, the M1A1 Carbine was the only World War II American small arm designed specifically for airborne use. The Second World War ended with the carbine firmly entrenched in the U.S. military’s inventory, and the M1A1 Carbine a mainstay of the American airborne units.

Following the war, the majority of American military arms—including carbines—were overhauled. The overhaul process consisted of inspecting the guns, disassembly, performing necessary repairs (including refinishing when required) and replacement of worn, broken or superseded parts. The carbines, including the M1A1, were typically fitted with updated parts, including adjustable rear sights, T4 barrel bands (with a bayonet lug), round bolts and rotary safeties. The earlier high-wood stocks were usually modified to the low-wood configuration as part of the rebuild procedure.

After overhaul, there was no effort made to replace the original barreled action in a refurbished M1A1 stock. Thus, while all original M1A1 carbines were made by Inland, a rebuilt example, conceivably, could have a barreled action made by any of the 10 prime contractors installed during the overhaul process. Regulations called for the identifying initials of the rebuilding entity to the stamped on the stock (typically the left side) after overhaul. Ordnance facilities that overhauled carbines in the post-World War II period included:

RIA: Rock Island Arsenal

RIA: Rock Island Arsenal

SA: Springfield Armory

AA: Augusta Arsenal (usually followed by another single letter)

RA: Raritan Arsenal

RRA or RRAD: Red River Arsenal or Red River Army Depot

SAA: San Antonio Arsenal

BA: Benicia Arsenal

AN: Anniston Arsenal

The most common rebuild markings found on M1A1 Carbine stocks are those of Rock Island, Springfield or Augusta, although others may be noted. The Springfield Armory also fabricated some M1A1 stock components after World War II, which can be identified by the “SA” markings. These parts would only be found on post-World War II rebuilt examples.

Arsenal-overhauled M1A1 carbines were equal to factory-original carbines in functioning and performance as they were rebuilt to as-new standards. For today’s collectors, however, rebuilt examples do not typically have the same desirability or value as do specimens remaining in their original World War II factory configuration. For this reason, the practice of restoring overhauled carbines has been popular among many collectors. This process typically involves substituting the updated parts that were replaced during the overhaul procedure with the correct type of parts as installed at the factory. Some restorers go so far as to sand off—or otherwise remove—the arsenal-rebuild stamps on overhauled stocks. It should be noted that there is a big difference between original parts and correct parts. A restored carbine might be made correct, but it can never be made original. The wisdom and ethics of restoring overhauled arms is the subject of debate among many collectors today.

In addition to restored examples, there have been many reproduction M1A1 Carbine stocks commercially manufactured for the past 30 years or so. Some of these are reasonable facsimiles of the originals, while others vary in a number of respects. None of the reproduction M1A1 stocks remotely approach the value and desirability of genuine examples, rebuilt or otherwise.

Genuine M1A1 Carbines are extremely popular in the collector market today, and prices are rising dramatically. Examples now change hands for prices that would have seemed almost unimaginable just a few years ago. The huge price differential between reproduction and original M1A1 stocks makes positive identification very important. There are several features to examine when attempting to identify a genuine M1A1 carbine stock. The most important are as follows:

- The inside of the stock (the barrel channel) will be marked “OI.” This denotes that the stock was manufactured by the Overton Company for Inland (Overton-Inland).

- The underside of the pistol grip on the First Contract M1A1 Carbines was also marked “OI” along with a small Ordnance Department crossed cannons escutcheon. Later production pistol grips were typically marked “RI/3.” These were made under subcontract by the J.S. Richardson Company (Richardson-Inland). On most of the later grips, a larger Ordnance escutcheon was stamped on the right side rather than on the bottom of the grip as found on the earlier examples. The configuration of many of the later grips was also somewhat different than the earlier examples.

- The inside of the metal buttplate had a drawing number cast (not stamped). The number, “B257614,” was followed by an asterisk-shaped marking enclosed in a circle (sometimes described as a wagon wheel) followed by a one- or two-digit number. This marking is often rather indistinct and can be hard to read. Reproduction M1A1 buttplates are usually unmarked although some fakes may be noted with a stamped (not cast) number.

- The early stocks typically had a circled “P” proofmark stamped on the rear of the stock. This marking was not generally found on the later stocks. It should be noted that many of the post-war rebuilt stocks had a proofmark applied as part of the overhaul procedure, but this was often a block letter “P” (not enclosed in a circle).

- The leather cheek pad was neatly attached to the stock and secured by rivets. Some rivets marked “7/4” have been observed, and these are believed to have been automotive brake shoe rivets made by Inland. Early rivets for the M1A1 cheek pad were typically made of brass, while most of the later rivets were made of Parkerized steel and usually painted brown to match the leather. The leather of the original cheek pads was fairly thin, and some original stocks have deteriorated or damaged pads. Some owners choose to replace the missing or damaged pads with newly made leather pads. Original leather pads will show evidence of factory-quality workmanship, whereas many of the replaced pads are somewhat ill-fitting or fabricated using leather that is too thick and/or too light in color.

After World War II, large numbers of carbines, including many M1A1s, remained in Uncle Sam’s arsenal and later saw use during the Korean War in the early 1950s. Although there were no selective-fire (M2) variants of the M1A1 Carbine manufactured, there have been some post-war overhauled M1A1 stocks noted with the inside of the stock routed out to accommodate the M2 Carbine’s fire-selector lever.

A number of M1A1 Carbines were subsequently supplied to American allies after World War II under various military assistance programs. Some of these saw action in the hands of French paratroopers in Indochina, including the ill-fated defense of Dien Bien Phu. Some M1A1 Carbines were later used by American troops and our South Vietnamese allies during the Vietnam War.

Few U.S. martial arms are as popular with today’s collectors as the M1A1 Carbine. The M1A1’s historic background, association with the elite airborne units, limited availability and unique appearance combine to make it a highly sought-after, and usually rather expensive, martial arm. A genuine M1A1 Carbine is one of the classic American arms of the Second World War and a true collector’s prize.