Maj. Gen. Charles M. Wesson, Chief of Ordnance, U.S. Army, takes aim with the first Winchester-made M1 rifle to roll off the firm’s production line on January 10, 1941. To the general’s left is John Cantius Garand, inventor of the M1 rifle.

This article was first published in American Rifleman, April 2005

To most gun enthusiasts, the name Winchester typically conjures up images of lever-action rifles or slide-action shotguns. For many years, the Winchester Repeating Arms Co. of New Haven, Conn., manufactured myriad types of high-quality firearms for the civilian market. Although the company gained fame for its sporting firearms, Winchester was also an important supplier of military arms to the U.S. government from the late 1870s through the early 1960s. While its trademark lever-actions were not embraced by the American military, Winchester produced a number of firearms under government contract during the latter part of the 19th century, including several types of bolt-action Hotchkiss rifles and carbines and the Model of 1895 6 mm Lee Navy straight-pull rifle. During World War I, Winchester delivered large numbers of U.S. M1917 Enfield rifles to the government along with some Model of 1918 Browning Automatic Rifles (BARs) and Model 1897 trench and riot shotguns.

When war broke out in Europe in 1939, the United States was shaken out of its between-the-wars lethargy and formulated plans to rearm our ill-equipped military. The semi-automatic M1 Garand rifle was adopted in 1936 but, initially, production proceeded at a rather slow pace at the government-owned and -operated Springfield Armory. When it became obvious that the U.S. military would soon require additional quantities of service rifles, Springfield Armory was ordered to boost production of the M1 rifle. Even with this increased output, however, a secondary source of Garand rifle production was needed.

To this end, a number of commercial arms manufacturers were approached regarding the possibility of producing M1s under government contract. Several firms submitted bids and, after some negotiation, Winchester was selected. It is likely that the company’s past experience as a supplier of small arms to the U.S. military played some role in the company’s selection.

Educational Order Rifles

On April 4, 1939, Winchester was granted an Educational Order (Contract #W-ORD-343) for 500 M1 rifles along with one tool, fixture and gauge for each part. The reason for such a small quantity was to determine the company’s suitability for manufacturing the rifle prior to the granting of a large production contract. If, after completion of the initial Educational Order, the company—or the government—was not satisfied, Winchester could bow out of any subsequent orders and other potential manufacturers would be sought for the rifles.

Winchester designated the Garand rifle as the Model 39 in internal company documents and records. Winchester was assigned the serial number range of 100,001-100,500 for the Educational Order M1s. As Winchester tooled up to produce the 500 M1 rifles, the Ordnance Department ordered several changes to the initial specifications. The most significant of these changes was the configuration of the gas system. The M1’s original gas system was of the so-called “gas trap” variety. After the rifle was introduced in service, this gas system proved to have some faults. A redesigned and improved “gas port” system, which utilized a hole drilled in the barrel to vent the gas necessary to operate the action, was developed and adopted. This change in gas systems for the Winchester M1 rifles was approved on July 13, 1940, and an additional $9,030 was granted to the firm to cover the costs of the manufacturing changes. Since Winchester was a civilian entity, the company had to be compensated for any changes to the original contract. Winchester did not manufacture any gas trap M1s.

There were the typical glitches inherent to the production of any new mechanical object, which resulted in some delay in initial production.

Even with Winchester’s well-established history of mass production of guns, a few components of the Educational Order M1 rifles required some hand fitting and finishing. A number of parts, especially stocks, showed evidence of being shaped by hand to the desired configuration. Regardless of these problems, the first 100 Educational Order M1 rifles were delivered by Winchester on December 27, 1940. The remaining rifles were completed by March 10, 1941.

Second Contract Rifles

Even while the Educational Order rifles were still being manufactured, Winchester was offered a contract for the production of 65,000 M1s. The company agreed to the proposal, and the contract was awarded on September 20, 1939. In order to help set up for mass production of the M1, representatives from Springfield Armory met with the Winchester management and engineering teams to formulate plans for greatly increased production of the Garand at the New Haven plant.

While superficially appearing to be cooperative, there was a surprising amount of friction, if not outright hostility, between the Winchester and Springfield Armory teams. Some internal Winchester documents had rather unkind things to say about the Springfield people. Likewise, some Springfield personnel were known to accuse the Winchester firm of everything from incompetence to greed. While the situation apparently improved a bit during the course of production, bitterness between the two entities lingered throughout much of the war.

The so-called Second Contract Winchester M1 rifles were serially numbered in sequence to the Educational Order rifles, 100,501-165,500. Production commenced in February 1941, and these rifles began to be shipped from the factory in April 1941.

The M1 rifles manufactured by Springfield and Winchester during this period were very similar. Many of the components, such as the receiver, operating rod, bolt, hammer and safety, were stamped with the initials of the manufacturer (“sa” or “wra”) and a drawing number that identified the specific part. The stocks were stamped with a circled “P” proof mark on the grip to denote that the rifle had been successfully proof-fired as part of the inspection process. Upon final assembly, a stamp, today often referred to colloquially as a cartouche, was applied to the left side of the stock to indicate that the rifle met all requisite inspections and was accepted into government service. Rifles manufactured by Springfield Armory were stamped “sa” over the initials of the commanding officer of the Armory at the time. The Winchester M1s were stamped “wra” (Winchester Repeating Arms) over the initials of the head of the Hartford Ordnance District, in which the company was located. The Educational Order Winchester M1s and early production Second Contract rifles were stamped “wra/rs” on the stock to indicate “Winchester Repeating Arms/Robert Sears.” Col. Robert Sears was replaced as the Hartford Ordnance District head in July 1941 by Col. Waldemar Broberg and the final inspection stamp was changed to “wra/wb.” There were two variations of Broberg’s inspection stamp.

As production continued, there were a number of design modifications instituted to speed production and/or improve the utility of the rifle. One noteworthy modification was the introduction of a hinged recess in the buttstock to store cleaning implements. Other changes included the elimination of the keystone-pattern operating rod spring that was replaced by a coil-type spring, incorporation of a relief cut on the rear handguard and, slightly later, an improved rear sight which included a locking bar to more securely hold the adjustments. These modifications were implemented at Springfield soon after adoption, as it only required the issuing of proper orders through channels to authorize such production changes. On the other hand, such alterations were not as easily accomplished at Winchester since the firm was a civilian entity.

Any changes to the original contract specifications required negotiation to determine appropriate compensation due to the company and the expected time-frame for the changes. Therefore, most of these modifications were generally instituted on Springfield M1s some months before they were incorporated on Winchester M1s. Some changes, such as the configuration of the safety, were never changed on Winchester rifles. In all fairness, with few exceptions, the various modifications were relatively minor and did not impair the overall effectiveness of the M1 rifle. There were some problems encountered fairly early in Winchester’s production with out-of-spec operating rods and similar issues, but these were resolved in short order.

Perhaps surprisingly, Winchester M1 rifles often left the factory with parts that were not, cosmetically speaking, as well finished as their Springfield Armory counterparts. Many of these parts evidenced signs of hasty production such as tool chatter marks, which indicated little polishing prior to finishing. It is a bit surprising that a company known for high-quality and beautifully finished commercial guns would turn out rifles with roughly finished parts. It is even more perplexing that, as a rule, many of the Springfield Armory parts of the same vintage were better finished. On the other hand, all M1s shipped out of the New Haven plant were passed by government inspectors and, thus, were as serviceable as their Springfield Armory counterparts. If an M1 passed inspection and was accepted into service, Winchester got paid. In wartime, functionality and production rate trump cosmetic considerations.

It is also important to remember that while Winchester was heavily involved in manufacturing the M1 rifle, the firm was producing large numbers of M1 Carbines (which the company developed) along with fairly sizeable quantities of Model 97 and Model 12 military shotguns.

Subsequent Contracts

As the war progressed, additional M1 rifle production contracts were granted to Winchester. Winchester was assigned additional serial number blocks for M1 rifle production in the 1,200,000 to 2,400,000 range. During the course of production, some of the updated components, such as the hinged buttplate recess and locking bar rear sight, were incorporated in the Winchester M1s. The final inspection stamp was changed to “wra/ghd” to represent Col. Guy H. Drewry who replaced Col. Broberg in June 1942. The majority of Winchester M1 Garand rifles were manufactured during Col. Drewry’s tenure.

Even though the M1s manufactured by Springfield and Winchester were functionally identical, there are some relatively minor differences in some of the parts between the two manufacturers, beyond the markings. For example, the protective ears of the front sight on Winchester rifles are noticeably wider than on the Springfield-made Garands (13/16" vs. 5/8" to 11/16"). Also, the locking bar of the Winchester M1’s rear sight is rounded on the ends, whereas the Springfield bars are square on the ends. Another difference is that the barrel ring on the Winchester M1 gas cylinder is rounded on top, but the Springfield gas cylinder barrel ring is milled flat in that area. Original Winchester gas cylinders had a slight bluish tint (Du-Lite), while the Springfield M1 gas cylinders were black (Molyblack). There were also rather subtle differences in the configuration of the Winchester and Springfield stocks. Regardless of these differences, all components of the M1 rifle were interchangeable between both manufacturers.

WIN-13 Rifles

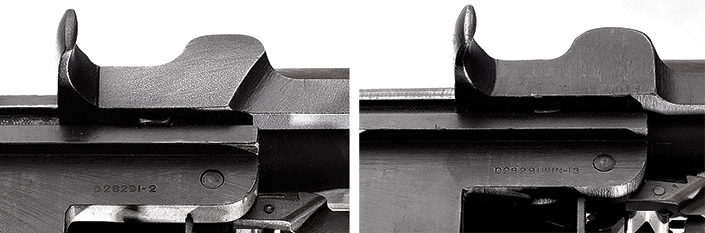

The final contract for M1 rifle production was granted to Winchester in February 1945 and was a bit of a departure from the previous WRA contracts in several respects. This last production run of rifles was assigned the serial number range of 1,600,000-1,640,000. This was unusual because this serial number range is much lower than the prior block of serial numbers assigned to Winchester. This is an obvious departure from the typical practice of ascending serial numbers as production continued. In other words, these rifles have much lower serial numbers than Winchester M1 rifles manufactured months, or even a couple of years, earlier. These final contract Winchester M1 rifles also had the receiver drawing number changed from “D282591-2” to “D28291 WIN-13” and are referred to by collectors today as “WIN 13” rifles. The reason(s) for the large numeric jump from revision No. 2 to revision No. 13 (and the addition “WIN” prefix) on the receiver is not known. Another difference between the earlier Winchester M1 rifles and the WIN-13 rifles was the change in the receiver bolt recess from a square to a round profile configuration.

Since the WIN-13 contract came late in the war, Winchester wished to use up any remaining M1 components on hand in order to keep from having unusable (and un-saleable) parts left over if the contracts were cancelled due to the winding down of the war. To this end, the WIN-13 rifles were assembled using a mixture of early and late vintage parts. To put it simply, whatever serviceable parts the company had on hand at the time were used to assemble these late production rifles, regardless of the vintage.

Winchester’s M1 production contract was cancelled in June, 1945, and the WIN-13 represented the last production variant of the Winchester Garand. By the time Winchester ceased M1 production, the company turned out a total of 513,880 Garand rifles as compared to just over 31⁄2 million by Springfield Armory. As was the case with the M1 rifles manufactured by Springfield Armory, the majority of the Winchester Garands were subsequently overhauled after the war. Any damaged, worn or superseded parts were replaced as part of the overhaul procedure. In many cases, the only Winchester part that remained was the receiver, and even that was invariably re-Parkerized.

Although the company did not manufacture any M1 rifles after World War II, large numbers of the refurbished Winchester M1s were issued during the post-war years. When the M14 rifle was adopted in 1957, Winchester received a production contract in 1959. It was initially believed that the company’s prior experience manufacturing the M1 would be helpful, given the similarities between the two arms. As events transpired, this perceived advantage did not materialize and Winchester had as much trouble as the other commercial contractors (Harrington & Richardson Arms Company and TRW) in getting into mass production of the M14 during the early 1960s. Eventually, Winchester produced 356,501 M14s, just over one-quarter of the total production.

The days of the M1 as a front-line, state-of-the-art service rifle are long past, but it has garnered much popularity in recent years with collectors and still enjoys success on the target range. Any M1 rifle can be a valued and desirable collectible, but the examples manufactured by Winchester will almost certainly continue to attract attention—and fetch prices—well out of proportion to their actual scarcity. The Winchester Garand is a great example of how America’s civilian arms makers assisted this nation’s efforts in time of war. Some may think of the Winchester lever-action as “The Gun that Won the West,” but it should also be remembered that the Winchester Garand (along with its Springfield Armory counterpart) was the gun that helped win World War II!