This article was first published in American Rifleman, August 2002

Some names are forever linked with certain types of firearms. For example, a mention of Samuel Colt conjures up images of Whitneyville-Walkers, percussion Navy and Army and Single Action Army revolvers. Likewise, John Browning’s name is related with an impressive variety of arms ranging from semi-automatic shotguns and pistols to automatic rifles to machine guns.

Other names, however, are inexorably linked to one specific firearm. A classic example is John C. Garand. Anyone with even the vaguest interest in military firearms will recognize him as the inventor of the famed “U.S. Rifle, Caliber .30, M1.” Indeed, the name “Garand” is synonymous with the M1 rifle.

The M1 rifle was the main U.S. rifle of World War II and the Korean War and remained in front-line service from the time of its adoption in 1936 until at least the early 1960s. Limited numbers are still in use today. While the undeniable success of the M1 rifle has firmly cemented John Garand’s place in the history of great firearm inventors, his basic design continued to live on with the M1’s successor, the M14.

The M1 rifle was the main U.S. rifle of World War II and the Korean War and remained in front-line service from the time of its adoption in 1936 until at least the early 1960s. Limited numbers are still in use today. While the undeniable success of the M1 rifle has firmly cemented John Garand’s place in the history of great firearm inventors, his basic design continued to live on with the M1’s successor, the M14.

The story of the M14 began during the latter part of World War II when an evaluation of the M1 rifle was conducted by the U.S. Army Ordnance Department. Although the Garand proved to be a superb battle arm, it had several perceived or real shortcomings, which included recurring complaints about its weight, the lack of full-automatic capability and the desire of many users to have a larger-capacity, detachable-box magazine rather than the M1’s eight-round “en bloc” clip.

In 1944, the government’s Springfield Armory was directed to fabricate an improved version of the M1 rifle with the following characteristics:

(1) 9-lb. weight

(2) Selective-fire operation (semi-automatic and full-automatic capability)

(3) 20-round detachable-box magazine

(4) Ability to readily launch rifle grenades

(5) Provision for mounting a bipod

John C. Garand was intimately involved at Springfield Armory in the modifications to his rifle required to achieve the desired characteristics. The prototype, designated “T20,” had provision for selective-fire operation and a detachable-box magazine, but the rifle exceeded the mandated 9-lb. weight limit. The T20 was thoroughly tested by the Ordnance Department, and minor changes were suggested. An order for 100,000 of the new prototypes, designated “T20E2,” was placed in 1945, but the war ended before the T20E2 could go into mass production, and only some 100 prototypes were fabricated. After World War II, Garand himself continued to be actively involved in the development of many Springfield Armory prototype rifles during the immediate post-war period.

In 1947, in conjunction with the formation of the North Atlantic Treaty Organization (NATO), the United States and several allies, including Great Britain and Canada, began discussions on a plan to standardize the small arms used by NATO member nations. World War II had shown that the lack of standardized arms and ammunition could cause logistical problems between and among allies. While the nations involved agreed on the desirability of such standardization, there was much disagreement on the exact type of arm and ammunition to be adopted. The British had a strongly held opinion that a small, lightweight rifle chambered for a .280-cal. cartridge would be ideal for the new NATO service rifle. The Brits also felt that such an arm could replace both the service rifle and the submachine gun. The Americans, on the other hand, believed that any reduction in caliber below .30 would be undesirable and pointed out that a new selective-fire arm firing a full-power cartridge could not only replace the service rifle and submachine gun, but also the automatic rifle. Initial meetings on the subject resulted in a stalemate, and the respective nations continued development of their own improved rifle and cartridge designs.

In 1950, the British had perfected what they felt would be an ideal rifle and cartridge for the purpose of arming NATO nations, an unconventional “bullpup” rifle—the “EM2”—chambered for a .280-cal. cartridge. The British submitted the EM2 rifle to the United States to be tested along with a more conventional rifle developed by Belgium’s Fabrique National. The latter, designated “FN-FAL,” was also chambered for the British cartridge. The test results of both rifles were relatively favorable, and the Belgian rifle was preferred by the United States Ordnance Department. The mild recoil of the .280 cartridge was cited as an advantage, but the Americans thought that the round was insufficiently powerful. Both rifles, and the .280 cartridge, were rejected by the United States, and, in 1951, Great Britain unilaterally adopted the .280 EM2 rifle.

As the United States was determining what type of service rifle should be considered to replace the M1, the issue of the optimum service cartridge was also being closely evaluated. As early as 1945, shortened versions of the standard “.30-’06” cartridge were being designed and tested at Frankford Arsenal. A cartridge of that type would enable the receiver and bolt of a rifle to be shorter, thus resulting in a lighter and more compact rifle while retaining the range and power of the longer .30-’06 Sprg. round. After a great deal of testing and development, the United States settled on the .30-cal. “T65” cartridge.

In an attempt to salvage the issue of standardization between NATO countries, it was suggested that the American T65 cartridge be designated as “NATO-standard” and the British EM2 and Belgian FN-FAL rifles be re-chambered for the new round. The other NATO nations agreed with the suggestion. With the decision made, Great Britain surprisingly discarded the EM2 and adopted the Belgian FN-FAL chambered for the T65 cartridge, which was now designated “7.62 mm NATO.”

With the cartridge issue settled, the remaining decision was which rifle would become the standardized NATO arm. The two contenders were the FN-FAL and a modified T20 rifle, now designated “T44.” Belgium, Great Britain and Canada officially adopted the 7.62 mm FN-FAL before a decision was made by the United States.

The U.S. Ordnance Department procured several thousand FN-FAL rifles for evaluation and testing and they were assigned the “T48” designation. Some of these were manufactured in the United States, and some were purchased from FN in Belgium. During 1955 and 1956, the T44 and T48 rifles were thoroughly tested, and it was eventually determined that both rifles were suitable for United States military use.

The U.S. Department of Defense finally announced on May 1, 1957, that the T44 rifle, rather than the T48, would be adopted to replace the M1, citing slightly lighter weight and ease of manufacture by U.S. firms. While not specifically stated, it was likely believed that the machine tooling still on hand to manufacture the M1 rifle could be used to produce the new rifle. NATO standardization notwithstanding, the U.S. decided to field its own new service rifle rather than adopt the FN-FAL.

The new U.S. service rifle was adopted as “U.S. Rifle, 7.62 mm, M14.” It was also announced that the new rifle would not only replace the M1 Garand but would take the place of the M1 and M2 Carbines, M3 and M3A1 submachine guns and the Browning Automatic Rifle. The latter was slated to be replaced by a heavy-barrel version of the M14, the “M15.”

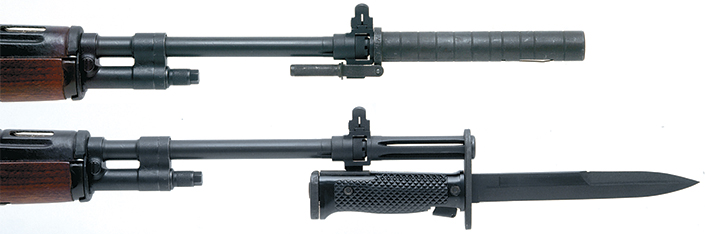

The M14 weighed 8.33 lbs. (without sling or magazine), which was substantially lighter than the 9.5-lb. M1. A loaded 20-round magazine weighed 1.07 lbs. An M14 and fully loaded 20-round magazine still weighed less than an M1 rifle with a eight-round clip. The M14’s barrel was 22" long (2" shorter than the M1) and was fitted with a flash suppressor.

Although there were obviously differences in the M1 and M14 rifles—including the design of the gas system and the incorporation of a detachable box magazine—there were also many similarities between the two that reflect John Garand’s original genius. Although not as long as the M1’s receiver (due to the difference in length between the .30-’06 and 7.62 mm NATO cartridges), the M14’s receiver design was nearly identical. One notable difference between the M1 and M14 receivers was the addition of an integral mount with a threaded screw hole on the left side of the latter rifle which permitted easy attachment of mounts for telescopic or night vision sights. Previously, such sights could only be used with the M1 by modifying the receiver or by installing a special barrel.

Both the M1 and M14 shared the same type of bolt mechanism, although the M14’s bolt had a “roller” to improve operation, especially in the full-automatic mode. Such a roller had been considered for the M1 as early as 1943 and was used on most of the T20-type prototypes. The M1 and M14 rear sights were mechanically identical, although the M14 was calibrated in meters rather than yards. Early versions of the M14 rifle used the M1 buttplate, but a buttplate having a hinged shoulder plate was soon adopted.

Early versions had a wooden handguard, but that was soon changed (circa 1960) to a slotted fiberglass type to prevent charring of the wood during automatic fire. The slotted handguard proved to be rather fragile and was eventually replaced by a solid fiberglass unit beginning in 1962.

Experimental work was also done with a fiberglass composite stock that was stronger and less susceptible to the elements than wood. The plastic stocks eventually saw widespread use with the M14 and proved to be quite serviceable, if somewhat less attractive, than the walnut or birch stocks.

M15 and M14E2

The M14 was capable of selective-fire operation, but the rifle was issued with a “selector lock” that permitted only semi-automatic fire. The M14 was very hard to control firing in the full-automatic mode, and incorporation of the selector lock was intended to limit potentially wasteful full-automatic fire. Converting the M14 to selective-fire operation only required removal of the selector lock and replacing it with a selector and selector spring. Although the “M15” was adopted to fill the role of a squad automatic weapon (SAW), very few were manufactured. Instead, the “M14E2” was developed, which was basically an M14 with selective-fire capability fitted with a modified straight-line stock with a folding front hand grip and bipod to assist in fully automatic fire. The changes eliminated the need for a separate variant, such as the M15.

Sniper Rifles

The integral receiver base on the M14 made it quite easy to adapt for use with a telescopic sight. Early versions of M14s used in sniper roles were fitted with Griffin & Howe mounts and M84 scopes, similar to the M1C sniper rifles of the post-World War II period. The M84 proved to be an inadequate scope, and the “ART” scope (Adjustable Ranging Telescope) developed by Leatherwood Corp. was adopted for use with the M14 sniping variants along with an improved mount. The first variant scope was designated as the “ART I.” In the early 1970s, the M21 sniper rifle was adopted along with the improved “ART II” telescope and a stronger mount.

Other U.S. military units developed even more refined M14-based sniper rifles during the mid to late 1980s. Some of those highly evolved M14 sniper rifles remain in limited use by our armed forces today.

M14 Production

The first M14 production contract was given to Springfield Armory on March 26, 1958. Even though it was initially envisioned that the M14 could be readily manufactured on existing M1 rifle production tooling, this proved not to be the case, and there were numerous unforeseen delays and “glitches” in setting up the M14 production line. Eventually, these problems were identified and addressed and the first 50 rifles were delivered to the Ordnance Department in July 1959.

In order to increase production capability and provide for geographic dispersion (which was viewed as an important factor in the nuclear era), several commercial firms were granted contracts for M14 production. Springfield Armory assisted these firms in the technical aspects of setting up their M14 production lines.

Springfield Armory manufactured a total of 167,173 M14s between July 1959 and October 1963. As was the case with M1s made by Springfield, many M14 components were marked “SA” to identify the manufacturer. Some parts were stamped with their drawing numbers and steel “heat lot” code. Barrels were also marked with the year and month of manufacture.

The second firm to receive a contract to manufacture the M14 was the Harrington & Richardson Arms Co. The firm had produced the M1 rifle from 1952 through 1956. H&R was the largest manufacturer of M14 rifles, and the firm turned out 537,512 between 1959 and 1963. Most parts on the company’s rifles were stamped “HRA” to identify the manufacturer.

The third entity to be awarded an M14 production contract was the famous firm of Winchester, by that time a subsidiary of Olin-Mathieson. Winchester produced 356,510 M14s between 1959 and 1963. Many of them were marked with a numeric code, “66118,” and some parts were stamped “OM” (Olin-Mathieson). The barrels were marked “Winchester.” As was the case with H&R, Winchester was a former manufacturer of the M1. However, unlike H&R, Winchester had not manufactured any M1 rifles since the end of World War II.

The final M14 contract was given to the firm of Thompson-Ramo-Wooldridge. TRW was a multi-faceted manufacturer, and one of its divisions produced sophisticated jet engine components. The company produced 319,163 rifles between 1961 and 1963. The M14 parts made by the company were marked “TRW.”

Even though all of the entities that received M14 production contracts (with the exception of TRW) had previous experience manufacturing the M1 rifle, there were a surprising number of problems encountered with the M14 program. The similarities between the M1 and M14 rifles were cited as a major advantage when the T44 was selected over the T48, but these “advantages” proved to be illusory. The problems encountered in the M14 production program were an embarrassment to the Ordnance Department and resulted in much negative publicity. The true reasons for the near-fiasco were many and varied, and they included allegations of inadequate funding, lack of technical support from the Ordnance Department and firms bidding too low on the contracts. It is interesting to note that the first commercial contracts set the per-unit price of each M14 at $68.75, which was substantially lower than the cost of the M1 rifle 20 years previously. Several of the firms were desperate to obtain M14 production contracts, but it was soon realized that the rifles could not be feasibly produced at that price. Subsequent negotiations resulted in the price being raised to approximately $95. Even that was quite a bit less than the M1 rifle cost during World War II (adjusted for inflation).

These production problems resulted in delays in getting the new M14s into the hands of “using services.” One of the first units to receive the new M14 rifle was the 101st Airborne Division in late 1961. The turmoil in Southeast Asia during that period gave renewed emphasis on improved infantry arms, and M14 production became even more of a priority. By the time of the “Cuban Missile Crisis” in 1962, many regular Army and Marine Corps units were fully or partially equipped with M14s.

As ever-increasing numbers of U.S. military personnel deployed to Vietnam, the M14 had its first major “baptism of fire.” As was the case with its predecessor, the M1, the M14 proved to be a reliable, accurate and hard-hitting military rifle. However, there were recurring complaints regarding the rifle’s weight, the weight of its ammunition, reliability, durability and inaccuracy. Also, the .30-cal. cartridge of the M14 was viewed by some as being unnecessarily powerful for many of the combat applications encountered in Vietnam.

As ever-increasing numbers of U.S. military personnel deployed to Vietnam, the M14 had its first major “baptism of fire.” As was the case with its predecessor, the M1, the M14 proved to be a reliable, accurate and hard-hitting military rifle. However, there were recurring complaints regarding the rifle’s weight, the weight of its ammunition, reliability, durability and inaccuracy. Also, the .30-cal. cartridge of the M14 was viewed by some as being unnecessarily powerful for many of the combat applications encountered in Vietnam.

The radical and unconventional Armalite AR-15 rifle chambered for a small-caliber, high-velocity 5.56 mm cartridge was evaluated for possible adoption by the U.S. military. The light weight of the rifle and the ammunition as compared to the M14 were considered to be significant advantages. The AR-15 was eventually adopted as the M16 and began to see wide issuance in Vietnam by the mid-1960s. The M16 eventually supplanted the M14 in front-line service, although a number of “end users” were not happy about it. Subsequent events proved that concerns about the M16 had merit. Early versions proved to be unreliable due to deficiencies inherent in the design of the rifle and the formulation of the cartridge’s powder. Eventually, the M16 and its ammunition were improved and almost totally supplanted the M14 as a U.S. service rifle.

A large number of M14s in the government’s inventory were destroyed (“demilitarized”) during the tenure of Secretary of Defense Robert McNamara. The rifles were typically destroyed by cutting the receivers in two with a torch or machine shear. The vast majority of the government’s M14 rifles, some in brand-new, unissued condition, were destroyed by the late 1960s or early 1970s. A few remained on hand for sniping use and other purposes, but only a relatively small percentage have survived.

The M1 rifle was unquestionably the premier battle rifle of World War II and is almost universally held in high esteem today. It is unfortunate, and more than a bit ironic, that its “product improved” successor, the M14, was conceived in international controversy between allied nations, was mired in production difficulties, was soon superseded by an arguably inferior rifle and most examples met the ignoble fate of being cut up for scrap metal. To many people today, the M14 is among the best, if not the best, military rifle ever devised. To others, it was an anachronistic relic of days gone by. The resemblance to its famous sire is unmistakable and, love it or loathe it, John Garand’s final legacy was the “U.S. Rifle, 7.62 mm, M14.”