On Feb. 27, 1918, two new automatic arms (the brainchildren of America’s genius arms designer John Moses Browning) were demonstrated before a select group of American political and military leaders, along with representatives of the French and British armed forces. The two machine guns were the Browning M1917 .30-caliber machine gun and the Browning Machine Rifle, also chambered in .30-’06 Sprg. You read that right: “Browning Machine Rifle.” The name of the legendary BAR, or “Browning Automatic Rifle,” took a little time to evolve in the common parlance of American troops and firearm enthusiasts alike.

The first known combat use of the Browning Machine Rifle came on Sept. 22, 1918, in the hands of the doughboys with the U.S. 79th Infantry Division near Avocourt, France, at the opening of the Meuse-Argonne Offensive. The BMR was issued to only four American divisions in the last two months of the war, the rest of the American Expeditionary Force struggling with and cursing their “damned and jammed” 8x51 mm R Lebel Chauchat automatic rifles. There were up to 17,000 BMRs in France by the end of July 1918, but Browning’s potent rifle was curiously withheld from general issue. Official explanations for why the Browning was kept out of combat are a bit hazy. They range from “not enough time for widespread training and deployment,” to supposed concerns that the Germans would capture one and quickly reverse engineer the firearm.

An Early Assessment From The Trenches

A recently uncovered U.S. Army document, dated Sept. 17, 1918, and originating from the “Automatic Arms Section” of the AEF’s Engineering Division, sheds some light on how the Browning Machine Rifle was viewed at the time of the great Allied offensive that would bring the Great War to an end. —James L. Ballou

The Browning Machine Rifle is the lightest automatic rifle in use by any of the nations now at war. On account of this light weight and its compactness it can easily be carried by the soldier in the same manner as an ordinary rifle and combines the advantages of the great fire power of an automatic rifle and the mobility of our service rifle. The barrel is the same as the barrel of a Springfield Rifle (Model of 1903) and the sights are the same as those on our Model of 1917 Service Rifle, so that the accuracy of the gun as a single shot weapon closely approaches that of our service rifle, in fact the accuracy of the weapon is usually greater than that of the soldier shooting it.

The similarity in appearance between a B.M.R. and our service rifle is so great that when the guns are in the field that they cannot be distinguished from each other at a distance greater than 50 yds.

Mechanically, the Browning Machine Rifle is more simple in construction than any other automatic rifle and has been dismounted and assembled as far as necessary for cleaning or changing spare parts in spare parts case in 55 seconds. The locking and unlocking section of the bolt is such that a full force of impact exerted against the gas piston is not transmitted directly to the rim of the shell but the bolt slowly acquires the momentum of the piston and slide due to the action of the link and hence the extraction troubles common to gas operated guns is eliminated. The buffer action reduces the shock of recoil to such an extent that the gun can be held steadily against the shoulder during automatic fire. By means of the change lever located just above the trigger guard the gun may be set for single shots, automatic fire or on safety.

The gun team for this rifle is composed of three men, namely, a gunner, loader and carrier. Nine hundred and sixty (960) rounds loaded in 48 magazines is carried by this team. The belt equipment is so arranged that it does not interfere with the carrying of the standard pack equipment, and is so compact that even with the 400 rounds the loader and carrier carry, they can double time or go into action the same as infantry.

The gun will be used for the most part as a rapid firing single shot weapon. It can be fired from the shoulder, kneeling or prone, the greatest accuracy, of course, being obtained in the latter position with the front of the forearm resting on some rigid body. In cases of emergency where the ammunition can be supplied, and where a large volume of fire is necessary, this gun will be fired automatically. Five hundred rounds were fired in 3½ minutes under field conditions, but this figure is a maximum for fire volume. Under ordinary conditions 300 rounds should be placed as a limit for continuous automatic fire except in cases of emergency.

General Description

The Browning Machine Rifle, Model of 1918, represents the latest development in automatic rifles for front line work. It is gas operated and air cooled. It may be set to fire single shots or automatically and may be fired conveniently from the shoulder or hip.

History

This rifle was patented by Mr. John M. Browning of Ogden, Utah, in 1917, and is manufactured by the Colts Patent Fire Arms Mfg. Co., Hartford, Conn., and the Winchester Repeating Arms Co., New Haven, Conn.

Miscellaneous Data

This gun fires U.S. Service Ammunition, Cal. .30, Model of 1906. The barrel is about the same weight as that of the Model of 1903 Springfield Rifle. It is air cooled, aided by no additional radiating device. The rate of fire of this gun is about 600 per minute. It is fed from a slightly curved metal magazine holding 20 or 40 cartridges whose weight load is one pound 7 ounces or two pounds 13 ounces. Weight of the gun, 15½ pounds.

Transportation

The gun is carried by means of a sling similar to that of the service rifle. The gunner carries the gun, spare parts kit and six magazines. A wide belt is provided for the carrying of the kit and magazines, to which is also attached a metal boot into which the stock of the gun fits and facilitates firing from the hip in marching fire. An assistant carries 20 magazines in a belt provided for that purpose and a second assistant carries 18 magazines.

Uses

The Browning Machine Rifle is used as an infantry weapon, 16 rifles being issued per infantry company for use in the front line trenches.

At the present time 27 divisions have been equipped with the Chauchat Auto Rifle, and two divisions with the British are using British .303 Lewis machine guns. All divisions over and above this number have been and are to be equipped with the Browning Machine Rifle.

In addition to the use of this gun as an infantry weapon, a number of requests have been received for its issue as an auxiliary anti-aircraft weapon. It is believed that when the supply of these weapons will permit, a large number will be employed for this purpose.

A Faithful Recreation In Semi-Automatic: Colt’s New 1918 BAR

Designed by John Moses Browning in 1917, the .30-’06 Sprg. Browning Automatic Rifle (BAR) was intended for use by the United States in World War I. In the fall of 1918, the U.S. military released a requirement for the BAR with Colt, Winchester and Marlin-Rockwell Corp. to produce 85,000 rifles. The BAR was rushed into service in September 1918, two months before the Armistice, but it had sufficient impact to continue in production after the war, when Colt started producing a commercial version.

The 1918 BAR was a selective-fire rifle operating by a long-stroke gas piston beneath its 24" barrel. A non-reciprocating cocking handle on the left side was pulled to the rear to cock the bolt and manually returned forward. Firing from the open bolt position, the breech was locked by a rising, tilting lock connected to the bolt, and forced up against a shoulder in the receiver by a toggle connected to the bolt carrier. This toggle doubled as a pivoting hammer, striking the firing pin as the bolt went into battery. The design was later inverted for use in the FN MAG 58 (U.S. M240) general-purpose machine gun.

Located on the left side of the receiver above the trigger, the 1918 BAR’s three-position selector was rotated to the rear to “S” for safe, to the middle to “F” for semi-automatic use and all the way forward to “A” for automatic fire capable of 500 to 650 rounds per minute. The BAR’s sights consisted of a front post and a rear folding leaf like that used on the U.S. Model 1917 (Enfield) rifle with a long-range tangent adjusting to 1,500 yds.

Within the front of the trigger guard was a button that was pushed forward to release the BAR’s 20-round, staggered box magazine. Takedown pins were equipped with perforated fins that could be dislodged using the point of a bullet to be rotated for removal in order to field strip the rifle.

The stock furniture of the 1918 BAR consisted of American walnut with the fore-end deeply checkered on both sides with a coarse crosshatch pattern. In conjunction with the rear of the receiver, the buttstock formed a pistol grip. The Model 1918 BAR was finished in blue. Unlike the successive U.S. and foreign versions of the Browning Automatic Rifle, the M1918 BAR did not use a bipod, a separate pistol grip or a shoulder rest.

In spite of its relatively heavy trigger, good accuracy from the 1918 Browning Automatic Rifle was possible in semi-automatic mode despite the movement of its open-bolt firing. Once sighted in, the rifle’s bolt jump was the same with every shot, especially when shooting from the prone position. A 4" tubular flash hider was standard with the 1918 BAR.

With the addition of an adjustable bipod and a folding shoulder rest on the butt, the Model 1918 BAR was adopted as the M1918A1 in 1937, but was short-lived, as in 1938 an improved version was issued, as the Model 1918A2. This BAR eliminated the semi-automatic setting, replacing it with a low rate-of-fire position providing 350-500 r.p.m., where single shots could be fired with trigger control. After the 1918 BAR, all successive models had a Parkerized finish. The Model 1918A2 served in the U.S. military into the Vietnam War with the U.S. Navy.

In 1996, Ohio Ordnance Works, in Chardon, Ohio, introduced a semi-automatic-only version of the Model 1918A2 BAR called the Model 1918A3 SLR (Self Loading Rifle). Firing from a closed bolt, this rifle was hammer-fired, and substituted the solid toggle hammer with one carrying an intermediate firing pin, which lined up with the main pin only when in battery. Following the Model 1918A3 SLR was a handful of semi-automatic rifles made in 1918 configuration using original 1918 components. Now there is a brand-new version.

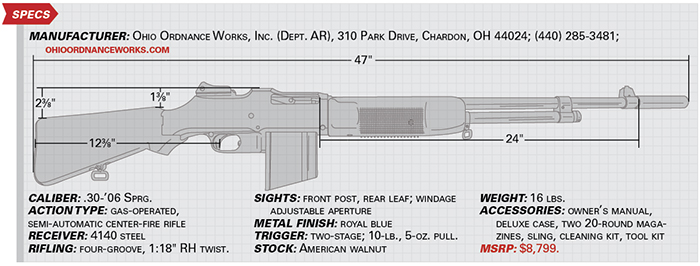

Called the Colt 1918 Self Loading Rifle, this BAR is manufactured by Ohio Ordnance Works, Inc., under license from Colt and is made with 100 percent new parts, including its CNC-machined receiver. In a nutshell, the new Colt 1918 SLR is identical to the original World War I 1918 BAR, but uses an improved version of the fire control group found in OOW’s 1918A3 SLR with a two-position “Safe” and “Fire” selector. The new rifle also uses a match-grade barrel from Bergara, of Duluth, Ga. Also standard is a deep royal blue finish and the Colt name along with its “Rampant Colt” trademark.

As with the Ohio Ordnance Works 1918A3 SLR, the cocking handle of the New Colt 1918 SLR is non-reciprocating, being used only to cock and load the rifle, returning forward with the bolt. It is otherwise identical to the original, excepting its markings, as noted.

The new Colt 1918 SLR comes in a deluxe Italian, fitted, hinged rifle case covered in leather with three built-in brass combination locks. The Colt name is not only found on the lid of the case, but is also imprinted in gold on the royal blue lining inside. Spaces to hold two deluxe blue 20-round magazines, an authentic style 1918 BAR leather sling, a removable toolbox, a cleaning kit and owner’s manual are also furnished.

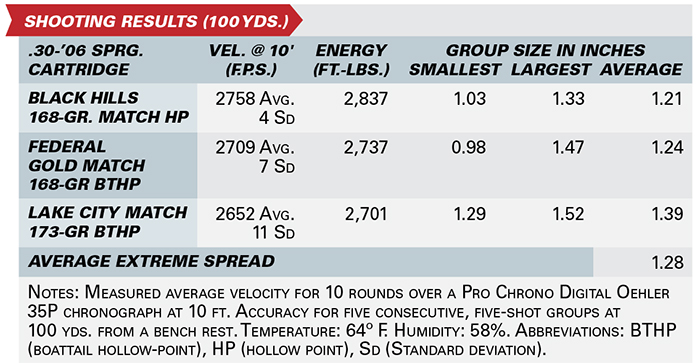

While the Colt 1918 SLR is an investment-quality collector’s rifle, it also comes ready for the range. In test firing the new Colt Model 1918, it operated smoothly in all respects with a relatively heavy trigger let-off of 10 lbs., 5 ozs. No malfunctions occurred and 100-yd. accuracy was very good fired from sandbags, as recorded in the accompanying table. Production will be limited to 1,000 units. —Gary Paul Johnston

The HCAR Turns A New Page In BAR History

After serving almost half a century as America’s first squad automatic weapon, the BAR was eventually replaced by the M14. The M14 never worked out very well in the role because it lacked the durability of the BAR and invited cook-offs since it fired from the closed bolt. In the 1980s, the role was filled by the M249 SAW, which did fire from the open bolt, yet many of the design lessons learned from the BAR were forgotten. There is no primary extraction, and the barrel is so lightweight that a second one must be carried to avoid cook-offs. The M249’s quick-change barrel feature is handy but contributes to the marginal accuracy of the design. The M249’s belt feeder is very reliable, while the back-up magazine feed is not. As for terminal effects, neither the 5.56x45 mm NATO M249 nor the 7.62x51 mm NATO-firing M14 have the punch of the .30-’06 Sprg.-chambered BAR.

The BAR is chambered for a cartridge that today’s modern militaries no longer use. As the gun is fully automatic, this precludes most civilian ownership. As a result, nobody thought about the BAR anymore. Nobody that is, except for Bob Landies, owner of Ohio Ordnance Works. Bob envisioned a semi-automatic BAR variant and believed there was a market for it.

The conversion from an automatic firearm into a “street legal” semi-automatic is no easy task. There are two components to the process: First is the mechanical conversion into what is hoped to be a reliable semi-automatic. The second is to pass examination by the Technology Branch of the Bureau of Alcohol Tobacco and Firearms (BATF). The BATF conducts a thorough examination to convince itself that there is no easy way to convert the rifle to fully automatic fire. It is this second component that presents a serious design challenge. Landies’ company had already distinguished itself by developing semi-automatic variants of full-automatic arms and breezed through the ATF review. Once the semi-automatic M1918 SLR design was approved, the gun went into production.

It wasn’t long after the M1918 SLR was fielded that the OOW team began getting feedback from customer surveys. Can I get a scope rail? How about a pistol grip? Where would I mount a bipod? Customers wanted modern features that were never intended to be offered on the original BAR or the M1918 SLR.

Landies’ team went right to work, setting the design goals for an M1918 SLR modernization program. Bob’s son, Robert, initiated the design work in what would eventually be called the Heavy Counter Assault Rifle or HCAR. He added the Picatinny rail and pistol grip, and then put the gun on a weight-reduction program.

In 2013, after Robert’s design was operational, they took the HCAR to SHOT Show and the NRA convention. People were very curious about it, but it still looked and felt like a hobby project with no real direction. Landies decided to bring in a consultant group made up of former military personnel. This group was certain there was a military application, since the ammunition offers better performance than the standard 7.62 mm NATO. Their design review resulted in additional changes that included a new safety, a better trigger, larger-capacity magazine and a means for the bolt to stay open on the last shot. One thing they all agreed on—with a reasonable trigger pull, the gun had the potential to be a real tack driver. At the 2014 SHOT Show the final design was introduced.

What impressed me about the transition of the HCAR from the original BAR was what I did not see. Too often new gun designs or conversions like this are chock-full of nuts, bolts and even lock washers that are used to attach the requisite additional parts. Such attachment efforts make the transition easy for the novice designer, while experienced designers understand that these fasteners just beg to be shaken loose during firing. Such is not the case with the HCAR. As new features were added, they were added without threaded fasteners and with a minimum of new parts in order to maintain overall reliability.

One major challenge in the HCAR design was the incorporation of a bolt hold-open mechanism. Bolt hold-back after the last shot fired is achieved by a lever that rotates into a slot that becomes vacated when the magazine is empty or not present. It’s a handy function that enables the user to hold the bolt back for other purposes too, such as inspection and cleaning. The trigger frame is made from polymer and maintains the two guide wings Browning purposed as an aid for rapid magazine change. The trigger frame is attached to the receiver by two quick-release pins that allow the entire unit to be removed for cleaning. The original BAR didn’t have a pistol grip, and I admit I’m not a fan of these for guns that are meant to be rapidly brought to the shoulder. Since the HCAR is a gun achieving best accuracy when fired from a bipod, the need is more apparent. The pistol grip helps the shooter pull the buttstock into the shoulder and aids in maintaining side-to-side orientation. When shooting the HCAR, you find yourself wondering why John Browning never added one.

The entire gun, even the reciprocating components, have been lightened by machine cuts. Lighter reciprocating components move faster during cycling, which requires a damping buffer at the rear of the stroke to moderate the overall speed of the cycle. The HCAR uses a hydraulic buffer for this, which is ideal because the amount of buffering is directly proportional to the speed of the impacting parts. This means the faster the moving part impacts the buffer, the more energy is removed, and their speed is reduced proportionately. Hydraulic buffers have improved through the years to the point where they don’t leak but do give reliable performance throughout the life of the gun. Case in point: the military’s M249 SAW and M240B medium machine guns both have them. To accommodate various loads, a dirty gun and different vintages of ammunition, the three-position gas system setting of the BAR has been maintained on the HCAR.

The chrome-molybdenum steel barrel is button-rifled with four grooves and has a 1:10" twist. Ohio Ordnance Works dimples the barrel exterior as an effective means of reducing the weight without a major impact on barrel stiffness. Fluting the barrel would have worked too, but dimples give it a more modern look. The entire barrel is nitrided inside and out to give it protection from the elements and a hard surface finish. The advantage of nitriding the barrel as opposed to chrome plating is that nitriding does not change the internal dimensions as much as chrome does, preserving accuracy while extending barrel life. There is no quick-change feature to the HCAR barrel, which allows the barrel to be supported the same way Browning intended, preserving system accuracy.

Like the trigger frame, the Picatinny rail fore-end and Magpul buttstock are also polymer components. While none of these are as durable as their metal counterparts could be, they weigh less, cost less and are easily replaced.

A 30-round magazine’s development came as a result of an M1918 SLR fan who found a photograph of a 40-round magazine, originally intended for times when the first BAR was to be used in the anti-aircraft role. This fan went so far as to make a brass extension for his 20 round magazine that increased its capacity to 30 rounds. He showed up at OOW, insisted the company test it and suggested it should develop one for the HCAR.

The Landies team agreed but learned the hard way that there were huge challenges in manufacturing the 30-round magazine. Fortunately, like most engineering challenges, a problem only had to be solved once, and a reliable magazine was eventually developed. Like many other steel components of the HCAR, the magazine body is hardened by the liquid salt bath nitriding process to provide a hard finish and to add stiffness.

The rifle I received for testing was fitted with a beautiful Leupold Mark 6 scope and Harris BDM Bipod. This assembly, less magazine, weighed in at 14 lbs., 15 ozs. The first BAR tested at Congress Heights was 15 lbs., 8 ozs. with only iron sights and no bipod. All of the trigger/safety controls are positioned for easy access. The Magpul stock comes in handy with its six positions offering much needed adjustability to shooters who are not content with a standard length of pull.

The single-stage trigger pull felt a little on the heavy side. I measured it at 9 lbs., which I understand is out of specification for the normal HCAR’s delivered by Ohio Ordnance Works. Positioning the bipod at the end of the fore-end, for me, turned out to be an ideal spot and made me wonder how it ever ended up way out on the end of the barrel on the World War II version of the BAR.

The exterior of the HCAR I received was finished with the same liquid salt bath nitriding process found on most of the working parts. Not only does the process provide a hard, durable surface but also results in an attractive black finish. The HCAR’s aluminum parts are hard-anodized, which also creates a hard layer at the surface. For those who want a look that is both durable and unique, Cerakote coatings are also available for the exterior.

A nicely illustrated technical manual takes the owner through all of the necessary steps for disassembly and cleaning. I followed the manual during field stripping and cleaning operations, and had no issues.

Without a doubt, the HCAR offers a well-balanced shooting experience. Its accuracy is commendable, and for that reason the gun is enjoyable to shoot. The muzzle brake necessitates hearing protection and will be required if the gun is ever used in a hostile environment. I see this as a useful police arm. I do not see the necessity for one for every squad car, but certainly every SWAT team should have one. The availability of high performance ammunition in this highly accurate rifle makes it a sniper-grade rifle with excellent firepower and one hell of a punch. —George E. Kontis, PE