Schweizerische Industrie-Gesellschaft (SIG Sauer) began making pistols at its factory in Neuhausen, Switzerland, starting in 1919 with the Chylewski “Einhand.” That was followed by a series of military pistols based on the designs of Charles Petter that culminated in the Model 210 of 1949.

While internal business was good, SIG was prevented by the alpine nation’s strict neutrality laws from competing for lucrative military and police contracts in other countries.

That led to the purchase of German maker J.P. Sauer & Sohn in the early 1970s to produce SIG-designed pistols. The first fruit of that marriage was the full-size P220, sold 1977-80 in this country as the Browning BDA. Chambered in 9x19 mm, .38 Super or .45 ACP, the P220 was fed by single-column magazines. In the early 1990s, the 9 mm P220 replaced the venerable P210 in Swiss military service. The 9 mm P220 was only briefly imported into the U.S. and the .38 Super was dropped in 1997.

The P220 was followed in 1980 by the P225, a more compact version developed originally for the West German police, which issued it as the P6.

At about the same time, SIG developed the full-size 9x19 mm-cal. P226 for the U.S. military service pistol trials that eventually led to the adoption of the Beretta-made M9. SIG teamed with Saco Defense, then-maker of the M60 machine gun, to offer a pistol that was about the same size and weight as the U.S. M1911A1, but that offered a 15-round magazine capacity.

SIG partisans are prone to credit the Beretta victory in the pistol trials to political pressure, and cite the later adoption of the SIG P228 as the U.S. M11 compact military service pistol as proof. Regardless, the P226 became one of the most common police pistols, especially among U.S. federal agencies, including the Justice and Treasury departments.

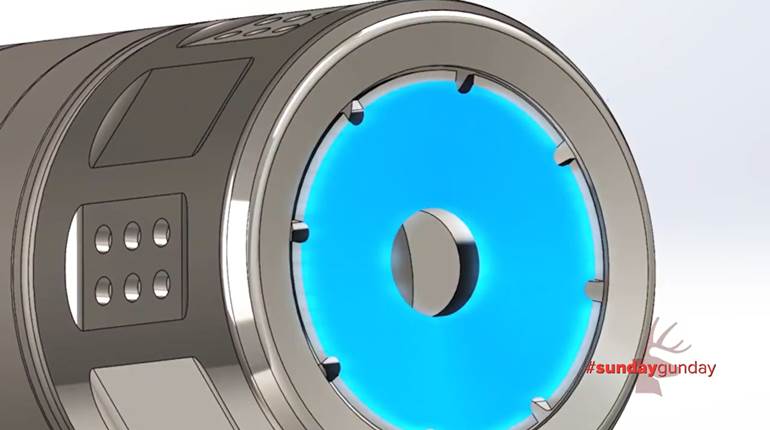

The most important features of the P226 and other Sauer-made SIG pistols are locking by a block at the breech end of the barrel against the front of the ejection port, and the frame-mounted decocking lever descended from the Sauer 38H pistol. The latter feature allows the loaded pistol to be carried ready for an immediate double-action shot, with the hammer safely lowered.

Some SIG models have had double-action-only lockwork. The accompanying drawing covers the decocker version.

Disassembly

Remove the magazine (51) and fully retract the slide (4) to ensure the chamber is empty. With the slide locked rearward, rotate the take-down lever (16) downward, then press the slide release lever (18) to allow the slide/barrel assembly to move forward off the frame (15). Next, turn the slide over.

Push forward on the recoil spring guide (2) then lift its rear end up and away from the barrel (1). Remove the guide and recoil spring (3). Next, lift the barrel up and out. This should be sufficient disassembly for routine maintenance and cleaning. Reassembly is in the reverse order.

The slide and breechblock (9) are separate parts joined by a nested pair of roll pins (7, 8). Drive these out in order with a suitable punch, which allows the breechblock to be removed downward out of the slide. The extractor (10), firing pin (11), firing pin spring (12), safety lock (13) and safety lock spring (14) may then be removed from the breechblock.

Rotate the take-down lever to point forward, then slide it to the left out of the frame. This allows removal of the locking insert (17) and the slide catch lever spring (19).

Remove the four grip screws (50) and the grip plates (48, 49). Remove the trigger bar spring (23) from the trigger bar (22) and lift it from the frame. Drive out the trigger pivot (21) with a punch right to left and remove it. Lift the slide release lever out the top of the frame along with the trigger (20) and trigger bar.

Press up on the mainspring seat (36) and slide it out of the frame, allowing removal of the hammer strut (33), mainspring (34) and mainspring pin (35).

Unhook the decocking lever spring (42) from the decocking lever (40). The lever then can be pulled off the decocking lever bearing (41). Press the bearing through the frame and allow it to fall out. Drive the hammer pivot pin (31) with a suitable punch right to left out of the pistol’s frame and lift the hammer (29) up and out.

Reassembly is in the reverse order. Be certain to hold the decocking lever bearing in place when reinstalling the lever.

When installing the locking insert, be sure the trigger pivot cuts point forward; the left end is slotted so it can be turned for proper orientation. Also, ensure the slide catch lever is against the left side of the frame.

When reinstalling the take-down lever, be sure the locking insert is properly seated, then begin to press the lever in with its arm straight up. Turn it forward to push it home, then finish with the lever down to allow reinstal-lation of the slide.

When replacing the breechblock in the slide, use a slave pin to align the parts and drive it out with the larger of the roll pins.