June, 1974

Smith & Wesson is well known for high-quality handguns, but it is not generally known that this firm also produced shotguns. Double-barrel shotguns by this famous maker were discontinued about a century ago. However, the Springfield, Mass. firm reentered the shotgun market last year with two repeaters, the principal one being a gas-operated autoloader called the Model 1000.

Designed for field use, the Model 1000 is offered in 12-ga. only; with choice of various barrel lengths and chokes. It has a 2 ¾” chamber and fires standard and magnum 2 ¾” shells without adjustment.

This gun is produced for Smith & Wesson by Howa Machinery, Ltd., Nagoya, Japan. It was developed by Howa and has some minor modifications made by Smith & Wesson engineers.

As usual with gas-operated shotguns, the gas mechanism of the Model 1000 is in the front of the magazine tube, which is concealed by the fore-end. The barrel is fixed during firing, but can be removed easily without use of tools by following the well-written instructions furnished with the gun. This facilitates cleaning and permits changing of barrels. Spare interchangeable barrels with various lengths and chokes are available at extra cost.

Operation is by means of a short-stroke, floating hollow piston designed to give a prolonged push instead of a hammer-like blow. (For detailed explanation of this system, see Question and Answer “M14 Gas Cylinder,” The American Rifleman, Feb., 1963, page 64.)

Powder gas enters the hollow piston through a piston hole aligned with two ports in the barrel, and fills the space within the piston and cylinder. Initial movement of the piston takes the piston hole out of alignment with the gas ports and prevents further entry of gas. The trapped gas expands and drives the piston, piston connector ring, action bar assembly, and breechbolt base rearward. After these parts are driven back approximately 3/8”, the breechbolt base cams the locking block in the breechbolt downward out of engagement with the barrel extension. This gives time for the pressure in the barrel to drop before unlocking occurs.

When the piston hole aligns with the gas-escape slot in the cylinder, gas used to operate the mechanism is exhausted upward through two slots in the top of the fore-end. The piston and connector ring are stopped after 1-3/16” travel, but the action bar assembly and unlocked breechbolt continue to the rear until the fired shell is extracted and ejected. The rearward moving breechbolt cocks the hammer and compresses the action spring in the Buttstock. As the breechbolt is driven forward, it chambers a loaded shell.

A highly-desirable feature of the Model 1000 is its pressure-compensator valve assembly designed to stabilize variations in gas port pressures and thereby adapt the gun to a wide range of loads. Located in the front end of the gas cylinder, this valve assembly has a tough, springy plastic piece between two cylindrical metal parts. Gas pressure causes the plastic piece to be compressed according to the amount of pressure exerted, and thus varies the amount of space for gas expansion.

As with most semi-automatic shotguns, shells are loaded into the magazine through a port in the receiver bottom. A magazine capacity pin extending laterally through the magazine tube reduces total capacity of the gun to three shots as required by Federal Migratory Bird Regulations. Removing this pin increases the magazine capacity to three shells or total capacity of the gun to four. The gas system at the front of the magazine limits its capacity to three rounds although the total length of the tube and fore-end are quite long.

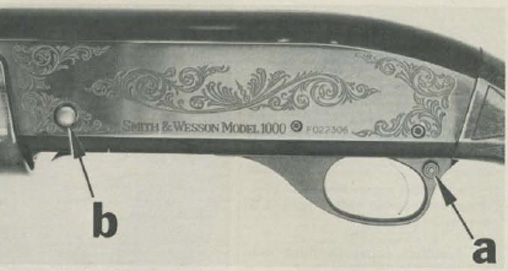

The crossbolt safety in the rear of the trigger guard has a red band that is exposed when the safety is disengaged. It can easily be reversed for left-handed use by following instructions provided with the gun.

A ventilated barrel rib fitted with front and mid-rib metal beads is a standard feature of the Model 1000. The rib is 5/16” wide and is finely checkered to reduce glare. The receiver top in line with the rib is finely grooved.

The gun has pleasing lines and a generally attractive appearance. Both stock and fore-end are well-figured, dark brown walnut with a high-gloss polyurethane finish. Cut checkering on the pistol grip and fore-end is about 20 lines per inch and of generally excellent quality. Fitted to the stock are a black plastic buttplate and grip cap separate from the wood by white plastic spacers. A round plastic inlay in the grip cap bears the Smith & Wesson monogram in silver-color letters on a blue field.

Made of aluminum alloy, the receiver and trigger guard have a black-anodized finish. The steel barrel is finished in a high-luster blue. The breechbolt assembly, trigger, and carrier are chrome plated. Both sides of the receiver are scroll engraved by an acid-etching process.

The Model 1000 shotgun evaluated by The American Rifleman Technical Staff has a 28” modified-choke barrel. This gun shows generally excellent workmanship and finish except that the hell of the buttplate projects slightly above the top of the stock. Also, some checkering in the border areas is not full depth and not quite as well executed as the rest of the checkering. This is a common fault even in many expensive custom guns.

Well proportioned, this gun points naturally, is easy to carry, and can be brought into action quickly. Point of balance is 7” forward of the trigger which makes the weight well distributed between the hands. Loading and unloading is easy, and the gun is convenient to use as a single-loader. The trigger pull weighs 4 ½ to 5 lbs. It has some creep, but this seems to have no adverse affect on the shooting.

The gun tested by the Technical Staff weighs only 6 ¾ lbs. which is light for a 12-ga. shotgun, especially for an autoloader. This is an advantage for an upland field gun where the gun is carried for long periods, but the lightness increases recoil. The recoil is not very great with light loads, and can be endured even in prolonged firing. It is much more pronounced, however, with heavy loads such as 3 ¾-dram equivalent. With magnum loads, recoil is severe. In firing 2 ¾” magnum loads, the heaviest for use in this gun, the computed recoil energy is 45 ft. lbs.

Approximately 475 light, medium, and heavy factory loads of several makes were fired in NRA tests of this gun, and there were only two malfunctions. One malfunction was a failure to chamber caused by the back of the shell swinging out to the right during feeding. The other was a failure of the breechbolt to latch in the open position after the last round in the gun was fired. Many loads firing during these tests were 2 ¾” magnums. Reloaded shells were also fired in the gun, and there were no malfunctions with them. During prolonged firing, the stock became slightly loose. This was easy to correct by removing the buttplate and tightening the back retainer bolt.

Tests for patterning were fired at 40 yds. using 3 ¾ dram equivalent factory loads with 1 ¼ ozs. No. 6 shot and plastic shot-container wads. The average pattern percentage or average number of pellet hits in a 30” circle was 67% for 10 shots, which corresponds to improved-modified choke results from this modified-choke gun. Distribution of pellet hits was only fairly even, with patchiness in many patterns. Point of impact at 40 yds. was 4.7” below point of hold.

The Technical Staff fired the gun extensively in skeet shooting. Handling qualities were generally very good and the gun pointed naturally and quickly. However, the low shooting proved a handicap, and results were only fair with several scores in the teens. The highest score was 23X35. Many targets were not broken cleanly indicating hits by edges of the patterns.

Except for its low shooting, the Model 1000 is a fine gun. Due to its lightness, it would be better suited for hunting upland game than waterfowl which requires use of heavy loads for good effectiveness.

Distributed by: Smith & Wesson, Springfield, Mass. 01101